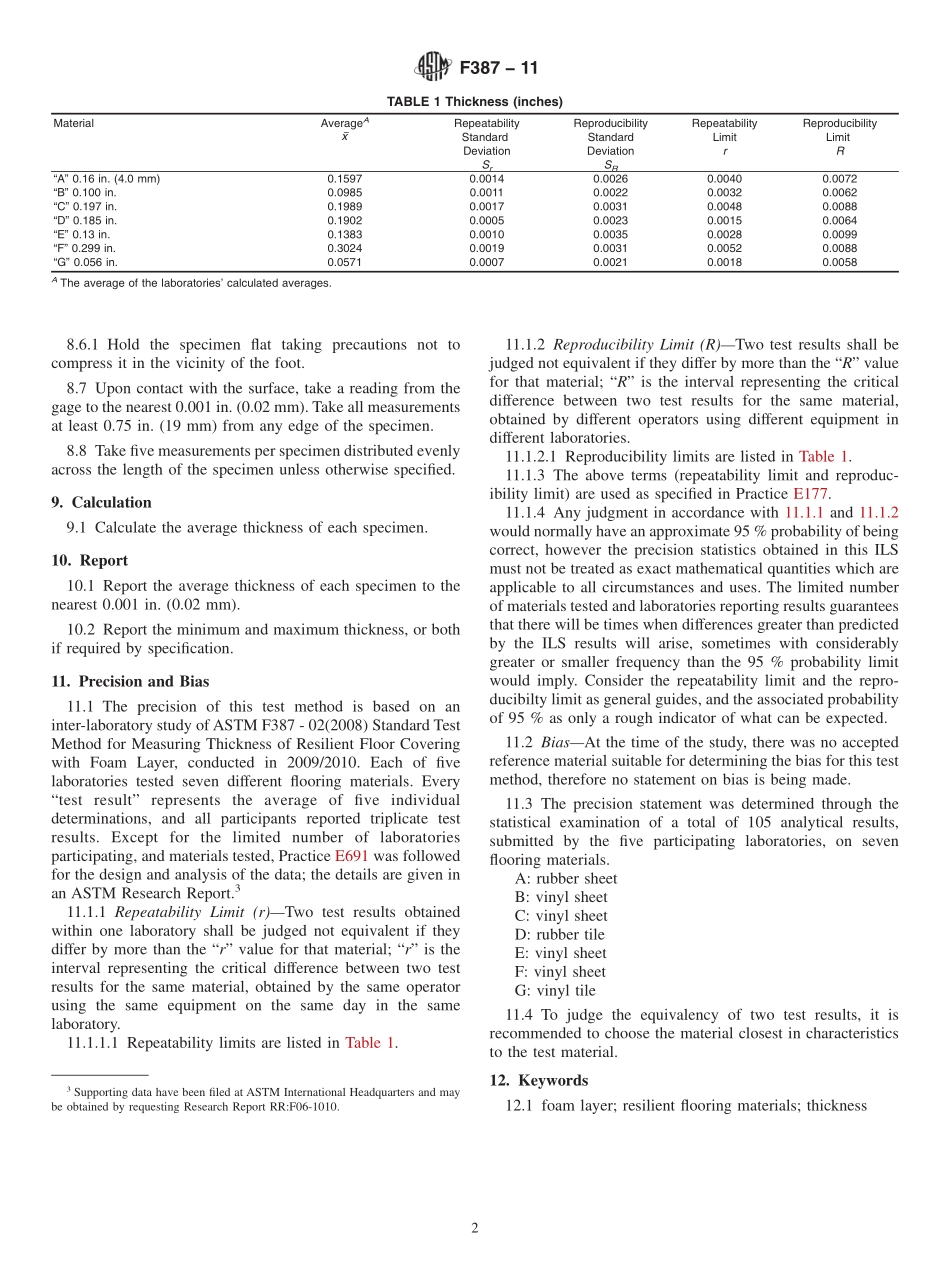

Designation:F387−11StandardTestMethodforMeasuringThicknessofResilientFloorCoveringWithFoamLayer1ThisstandardisissuedunderthefixeddesignationF387;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheDepartmentofDefense.1.Scope1.1Thistestmethodcoversthedeterminationofthethick-nessofresilientnon-textilefloorcoveringscontainingafoamlayeraspartoftheconstruction.1.2Thevaluesstatedininch-poundunitsaretoberegardedasstandard.ThevaluesgiveninparenthesesaremathematicalconversionstoSIunitsthatareprovidedforinformationonlyandarenotconsideredstandard.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2E691PracticeforConductinganInterlaboratoryStudytoDeterminethePrecisionofaTestMethodE177PracticeforUseoftheTermsPrecisionandBiasinASTMTestMethods3.SignificanceandUse3.1Theoverallthicknessorcaliperofresilientflooringisabasicphysicalproperty.However,conventionalmeansofmeasuringthethickness,suchasahandmicrometerorregulardialmicrometer,arenotapplicableforfoam-layerproductsduetotheerrorfromcompressingthefoam.Thistestmethodminimizesthistypeofmeasuringerrorandstillretainstheconvenienceandspeedofmeasurement.3.2Measurementoftheproductthicknessmayberequiredforqualitycontrolpurposesortoensurecompliancewithapplicablespecifications.4.Apparatus4.1Theapparatusshallconsistofacomparatorstandhavingaflatanvilbaseatleast6in.(15cm)square,equippedwithathicknessgagegraduatedto0.001in.(0.02mm).Thegageshallbeequippedwithaflatpresserfoot0.25060.01in.(6.3560.5mm)indiameter.Thefootshallexertaforceof160.1ozf(0.2860.03N)maximum.4.1.1Thec...