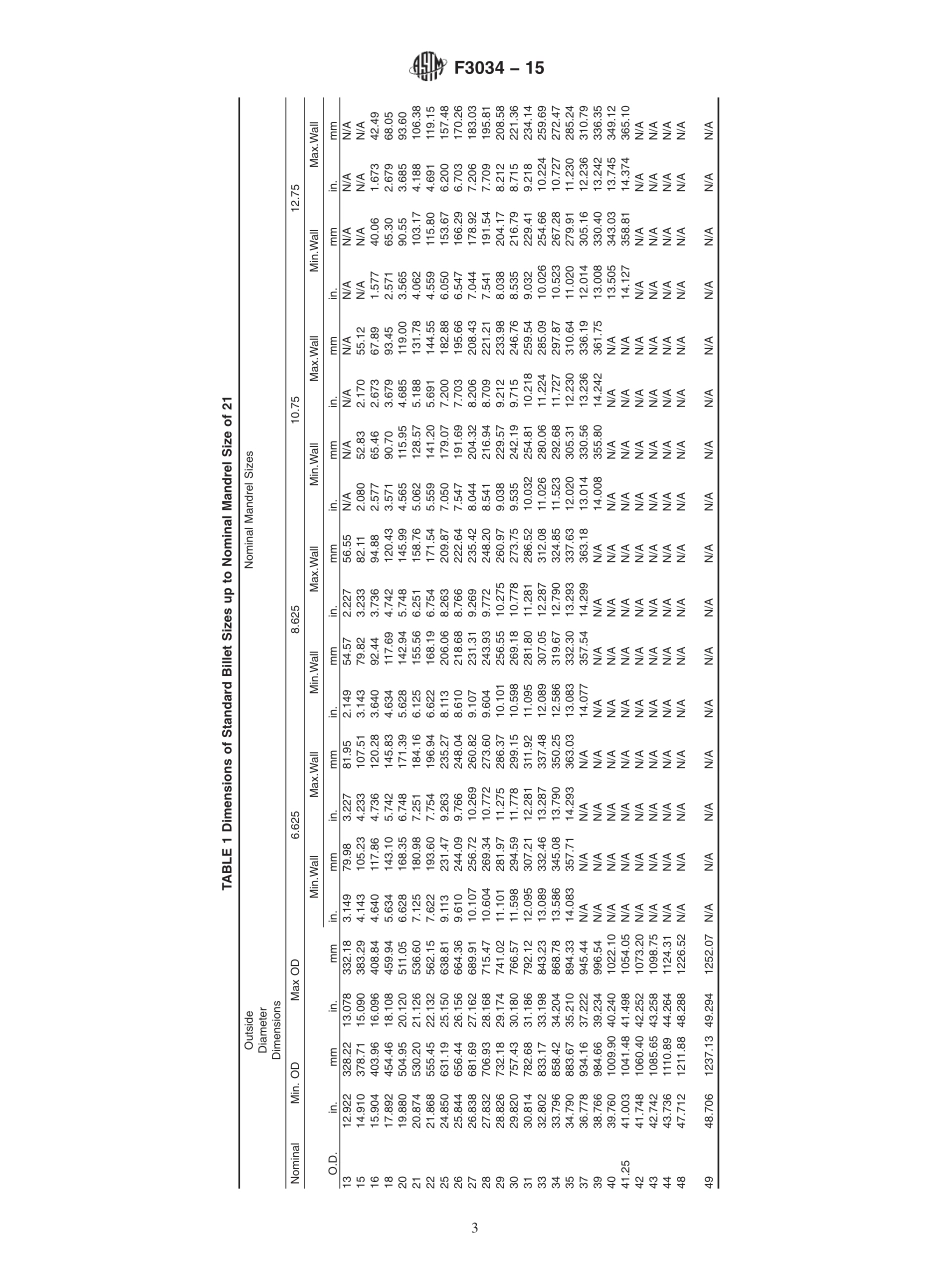

Designation:F3034−15StandardSpecificationforBilletsmadebyWindingMoltenExtrudedStress-RatedHighDensityPolyethylene(HDPE)1ThisstandardisissuedunderthefixeddesignationF3034;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope*1.1Thisspecificationcoversbilletsmadefromstress-ratedhigh-densitypolyethylene(HDPE)materials.1.2Thebilletsaremanufacturedbyapplicationofmoltenextrudedmaterialontoarotatingmandreltoformamonolithicmass.Removalofthemandrelprovidesabilletintheapproxi-mateshapeofathick-walledcylindricalshell.Machiningpriortodimensioningisacceptable.NOTE1—Althoughitisimpossibletoaddressallmanufacturingdetailsrelatedtothefabricationofbilletsinthisspecification,successfulheatfusionbondingofHDPEisobtainedthroughcontrolledapplicationofsufficientheattocausemeltingincombinationwithappliedforceoveraperiodoftime.1.3Thebilletsareintendedforfabricationintopipefittingssuchasflangeadaptersandreducers.1.4Requirementsforanduseofthefabricatedpipefittingsshallbeinaccordancewithanapplicableproductspecification.Thisspecificationforbilletsdoesnotincluderequirementsforitemsfabricatedfromthebillets.1.5Thisspecificationincludesthermoplasticpipematerialdesignationcodesforselectionofappropriatestress-ratedmaterial,togetherwithperformancerequirementsforbilletsandtestmethodsfordeterminingconformancewiththere-quirements.1.6Minimumqualitycontrolmeasuresareprescribedformanufacturers.SeeAnnexA1forqualitycontrolforbilletsconformingtothisspecification.1.7Thevaluesstatedininch-poundunitsaretoberegardedasstandard.ThevaluesgiveninparenthesesaremathematicalconversionstoSIunitsthatareprovidedforinformationonlyandarenotconsideredstandard.1.8Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafe...