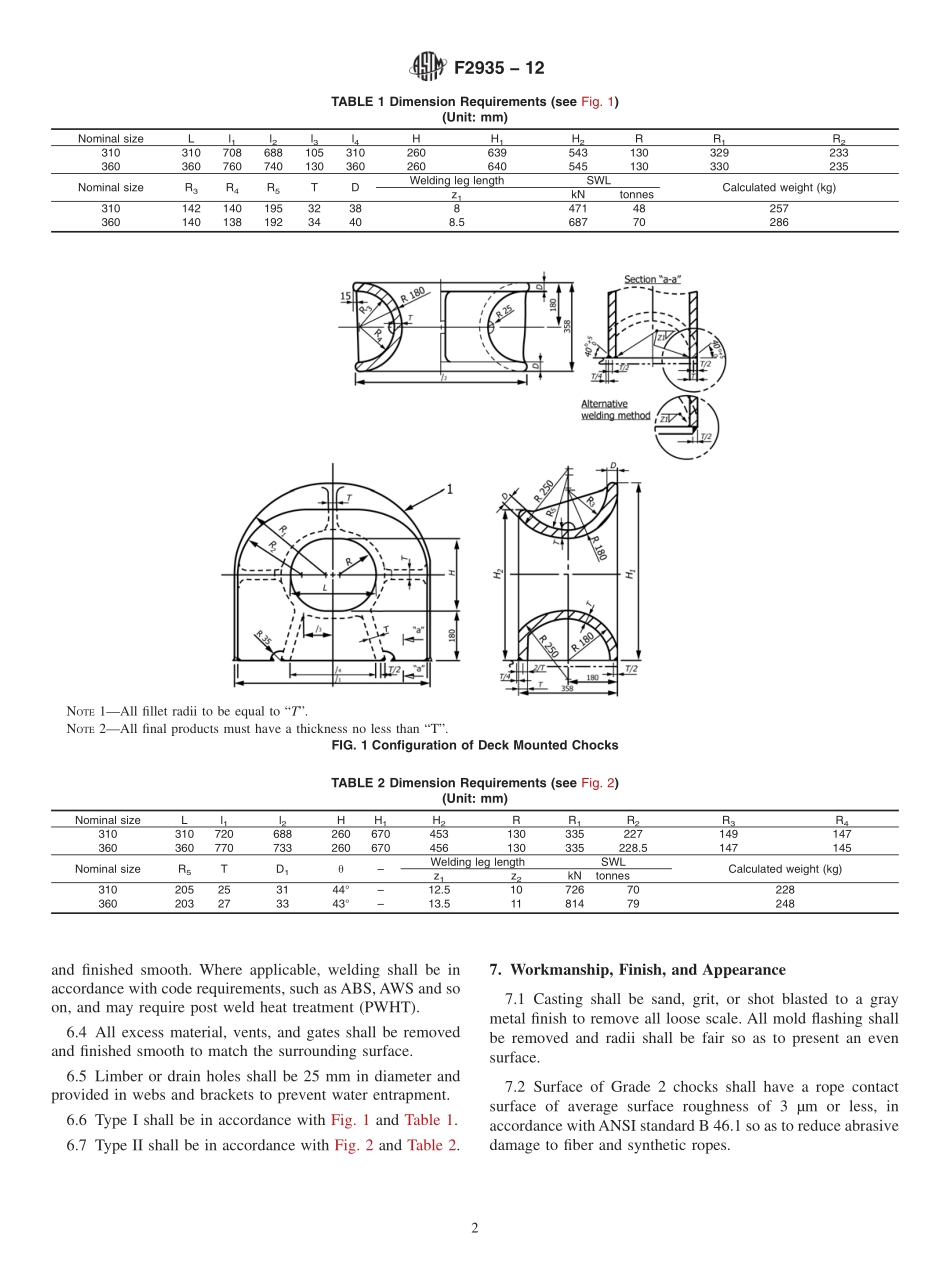

Designation:F2935−12AnAmericanNationalStandardStandardSpecificationforChocks,Panama,MooringCastSteel1ThisstandardisissuedunderthefixeddesignationF2935;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1ThisspecificationcoverstheprincipaldimensionsandmaterialsofchocksinstalledinshipstocomplywiththeregulationsofthePanamaCanal.1.2Chockscanbeusedwitheitherwireropeorfiberandsyntheticropes.1.3Chocksareformountingdirectlyonadeck,seat(foundation)orformountinginabulwark.1.4TomeetPanamaCanalCompanyregulationstheradiusofcontactsurfacesoflinesmustbe180mm.1.5ThevaluesstatedinSIunitsaretoberegardedasthestandard.2.ReferencedDocuments2.1ASTMStandards:2A27/A27MSpecificationforSteelCastings,Carbon,forGeneralApplication2.2ANSIStandard:3B46.1SurfaceTexture3.DescriptionsofTermsSpecifictoThisStandard3.1bulwark—astructuralenclosurealongtheedgeoftheshiptoserveasarail.3.2closedchock—ametalflaredring-likefittingmountedonashipthroughwhichmooringlinespasstotowormooraship.3.3mooringringorpipe—achockmountedinthebulwarkandconformingtoTypeIIorIV.3.4ropecontactarea—thatpartofthefittingincontactwiththemooringlineinnormalmooringoperations.4.Classification4.1Thesizeofthechockshallbeidentifiedbythenominalsize“L”and“H”oftheopeningasshowninTable1andFig.1,andTable2andFig.2.Sizeslargerthan360mmby260mmmaybeconsideredasdoublechocks.4.2Chocksarefurnishedintypesasfollows:4.2.1TypeI—Deckmounted,asshowninFig.1,andconformstoalldimensionsinTable1.4.2.2TypeII—Bulwarkmounted,asshowninFig.2,andconformstoalldimensionsinTable2.4.2.3TypeIII—Deckmountedconformingonlytodimen-sions“L”,“H”,and180mmradiusatentrance,asshowninFig.1andTable1andtherequirementsofSections6–10.4.2.4TypeIV—Bulwarkmountedconformingonlytodi-mensions“L”,“H”,and180mmradiusatentrance,asshowninFig.2andTable2andtherequi...