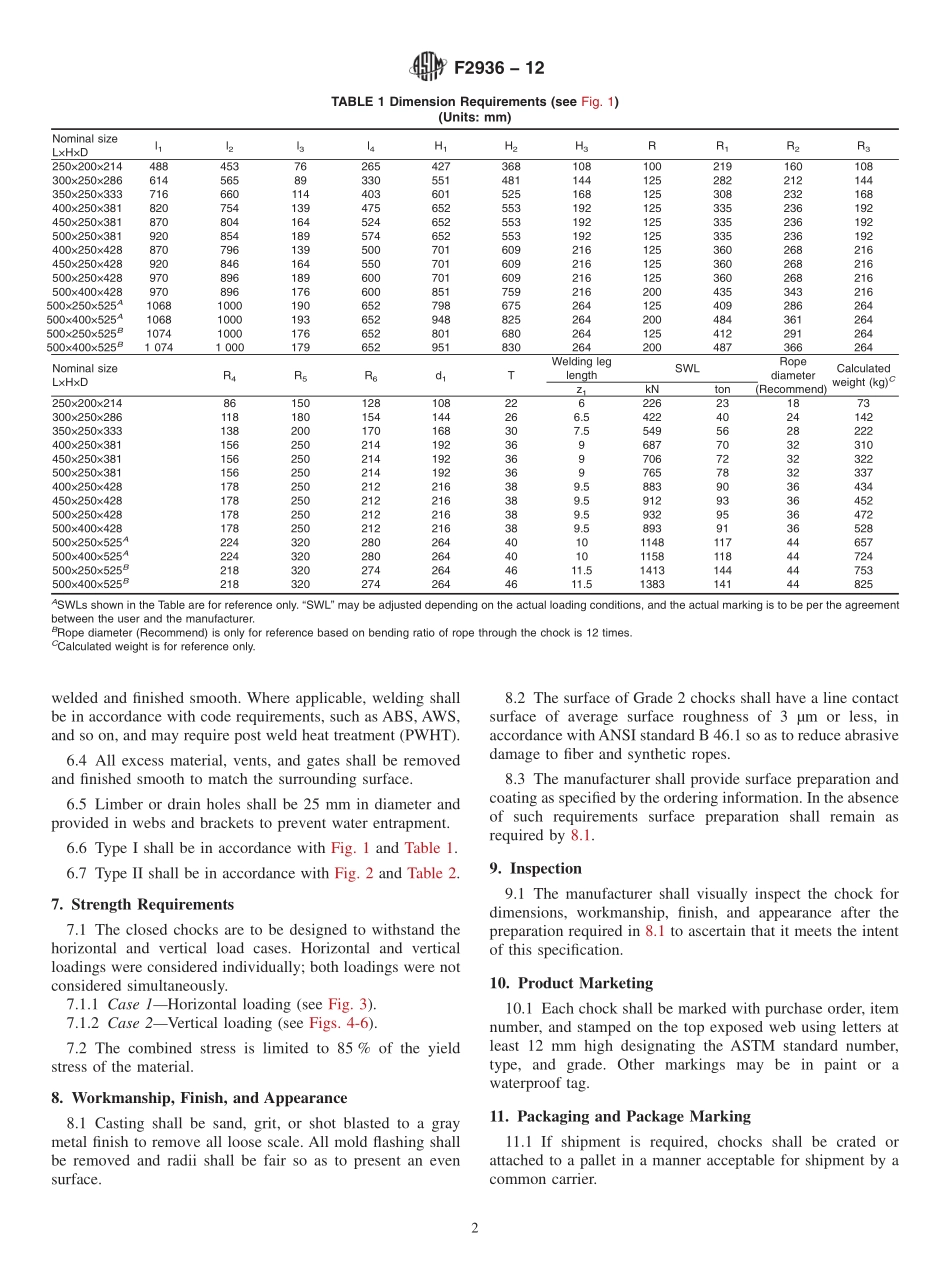

Designation:F2936−12AnAmericanNationalStandardStandardSpecificationforChocks,ShipMooring,CastSteel1ThisstandardisissuedunderthefixeddesignationF2936;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thisspecificationcoverstheprincipaldimensionsandmaterialsofclosedchocksforinstallationonshipsusedformooring.1.2Chockscanbeusedwitheitherwireropeorfiberandsyntheticropes.1.3Chocksareformountingdirectlyonadeck,seat(foundation),orformountinginabulwark.1.4ThevaluesstatedinSIunitsaretoberegardedasstandard.Nootherunitsofmeasurementareincludedinthisstandard.2.ReferencedDocuments2.1ASTMStandards:2A27/A27MSpecificationforSteelCastings,Carbon,forGeneralApplication2.2ANSIStandard:B46.1SurfaceTexture33.Terminology3.1DefinitionsofTermsSpecifictoThisStandard:3.1.1bulwark—astructuralenclosurealongtheedgeoftheshiptoserveasarail.3.1.2closedchock—ametalflaredring-likefittingmountedonaship,throughwhichmooringlinespasstomooraship.3.1.3mooringringorpipe—achockmountedinthebul-warkandconformingtoTypeIIandIV.3.1.4ropecontactarea—thatpartofthefittingincontactwiththemooringlineinnormalmooringoperations.4.Classification4.1Thesizeofthechockswillbeidentifiedbythenominalsize“L”and“H”oftheopeningasshowninTable1andTable2.4.2Chocksarefurnishedintypesasfollows:4.2.1TypeI—DeckmountedasshowninFig.1andconformingtoalldimensionsinTable1.4.2.2TypeII—BulwarkmountedasshowninFig.2andconformingtoalldimensionsinTable2.4.2.3TypeIII—Deckmounted,conformingonlytodimen-sions“L”and“H”ofTable1andisofadequatestrengthtoatleastmeet7.2requirementandtherequirementsofSections6to10.4.2.4TypeIV—Bulwarkmounted,conformingonlytodi-mensions“L”and“H”ofTable2andisofadequatestrengthtoatleastmeet7.2requirementandtherequirementsofSections6to10.4.3Chocksshallbefurnishedineitherofthefollowinggrades:4.3.1...