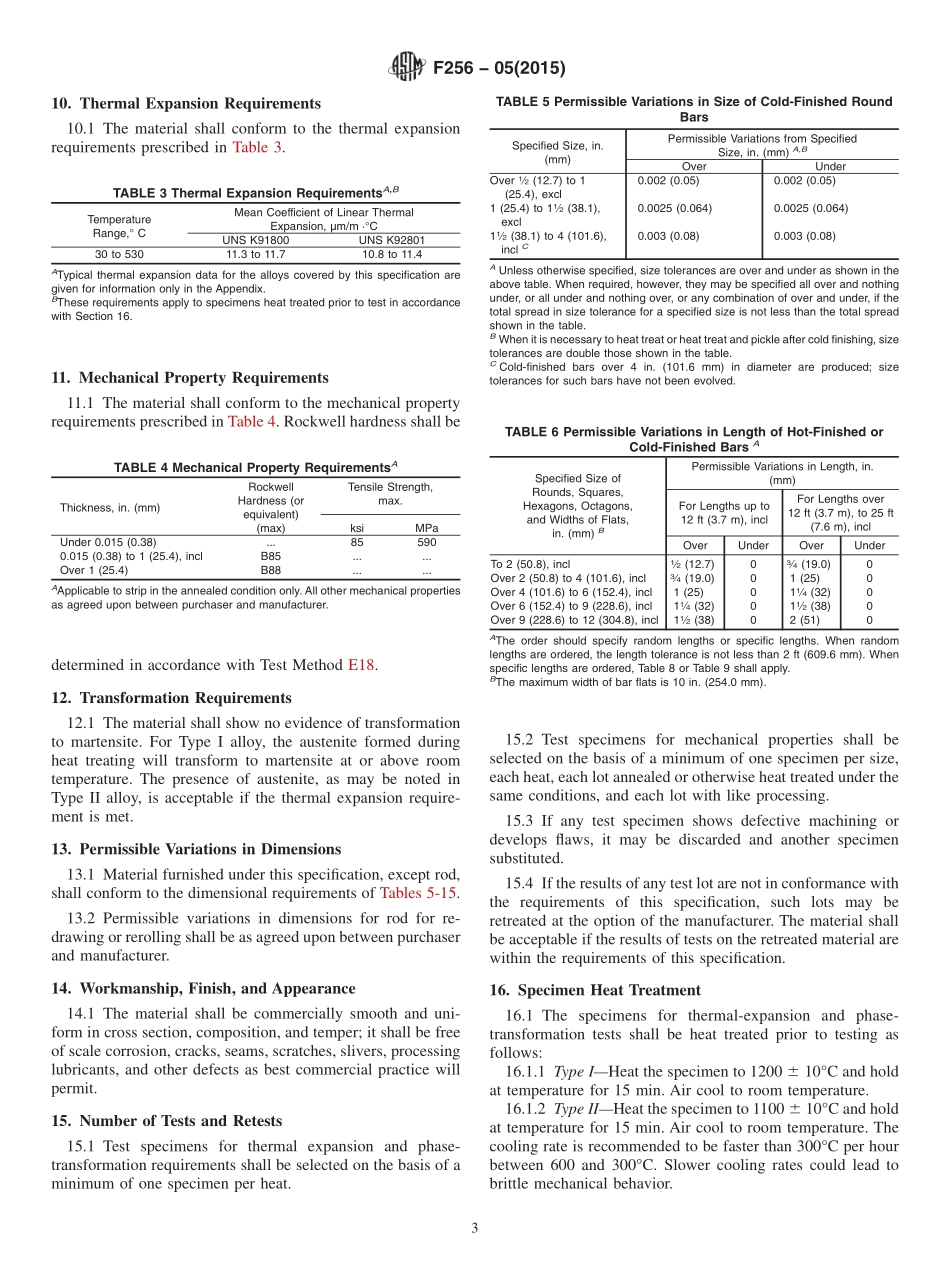

Designation:F256−05(Reapproved2015)StandardSpecificationforChromium-IronSealingAlloyswith18or28PercentChromium1ThisstandardisissuedunderthefixeddesignationF256;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thisspecificationcoverstwochromium-ironalloys,theformer,(UNSK91800),nominally18%chromium,balanceiron,thelatter,(UNSK92801),nominally28%chromium,instrip,bar,wire,androdformsintendedprimarilyforsealingtoglassinelectronicapplications.NOTE1—UNSK92801shouldonlybeconsideredforuseatservicetemperaturesbelow300°C.Thealloyispronetosigmaphaseformationattemperaturescloseto620°C,andexhibitsbrittlemechanicalbehaviorafterprolongedexposuresattemperaturescloseto475°C.1.2Thevaluesstatedininch-poundunitsaretoberegardedasstandard.ThevaluesgiveninparenthesesaremathematicalconversionstoSIunitsthatareprovidedforinformationonlyandarenotconsideredstandard.1.3Thefollowinghazardcaveatpertainsonlytothetestmethodportion,Sections16and17,ofthisspecification.Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappropriatesafetyandhealthpracticesanddeterminetheapplicabilityofregulatorylimita-tionspriortouse.2.ReferencedDocuments2.1ASTMStandards:2A370TestMethodsandDefinitionsforMechanicalTestingofSteelProductsE3GuideforPreparationofMetallographicSpecimensE18TestMethodsforRockwellHardnessofMetallicMa-terialsE29PracticeforUsingSignificantDigitsinTestDatatoDetermineConformancewithSpecificationsE38MethodsforChemicalAnalysisofNickel-ChromiumandNickel-Chromium-IronAlloysE228TestMethodforLinearThermalExpansionofSolidMaterialsWithaPush-RodDilatometerF14PracticeforMakingandTestingReferenceGlass-MetalBead-SealF140PracticeforMakingReferenceGlass-MetalButtSealsandTestingforExpansionCharacteristicsby...