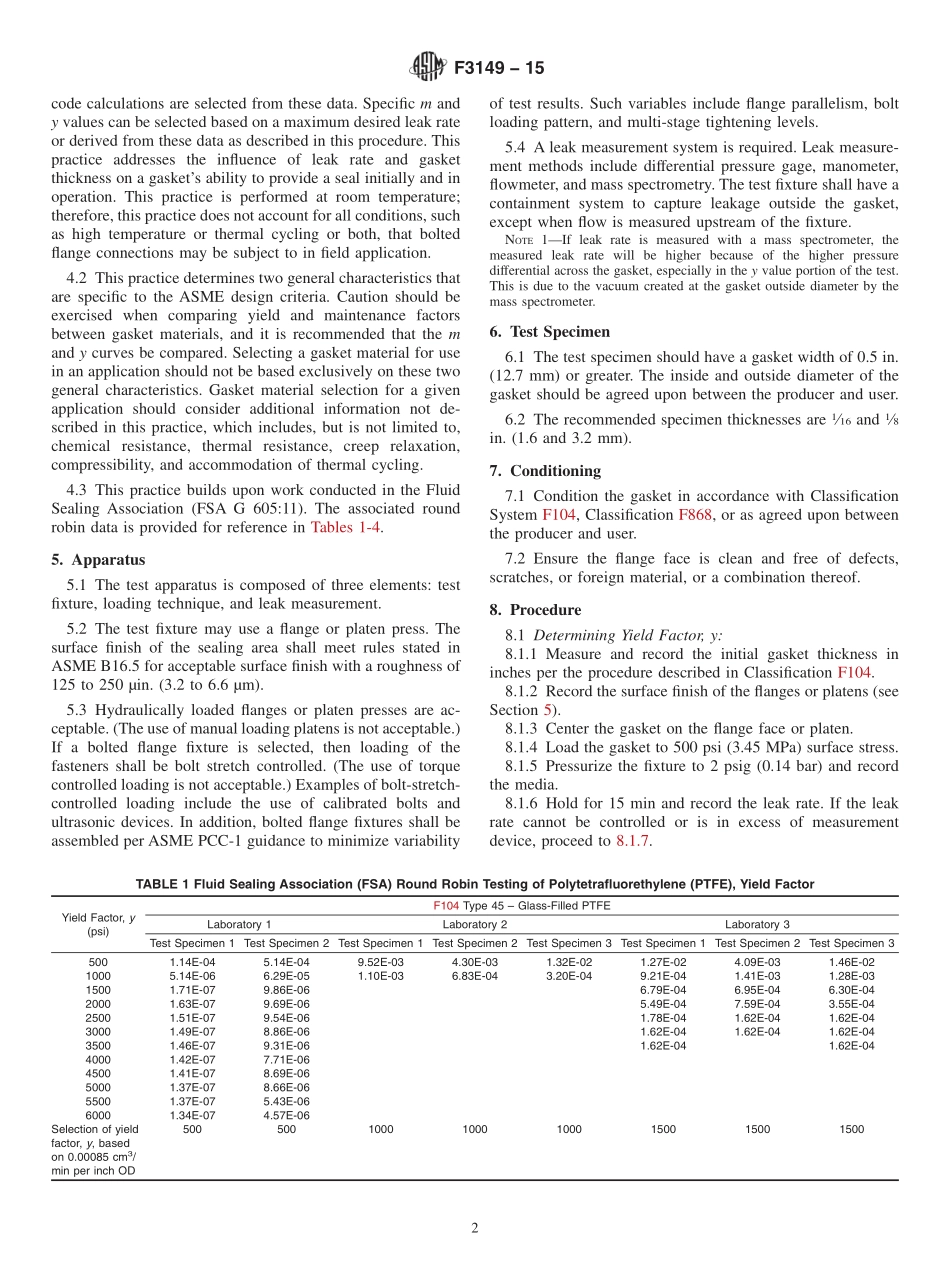

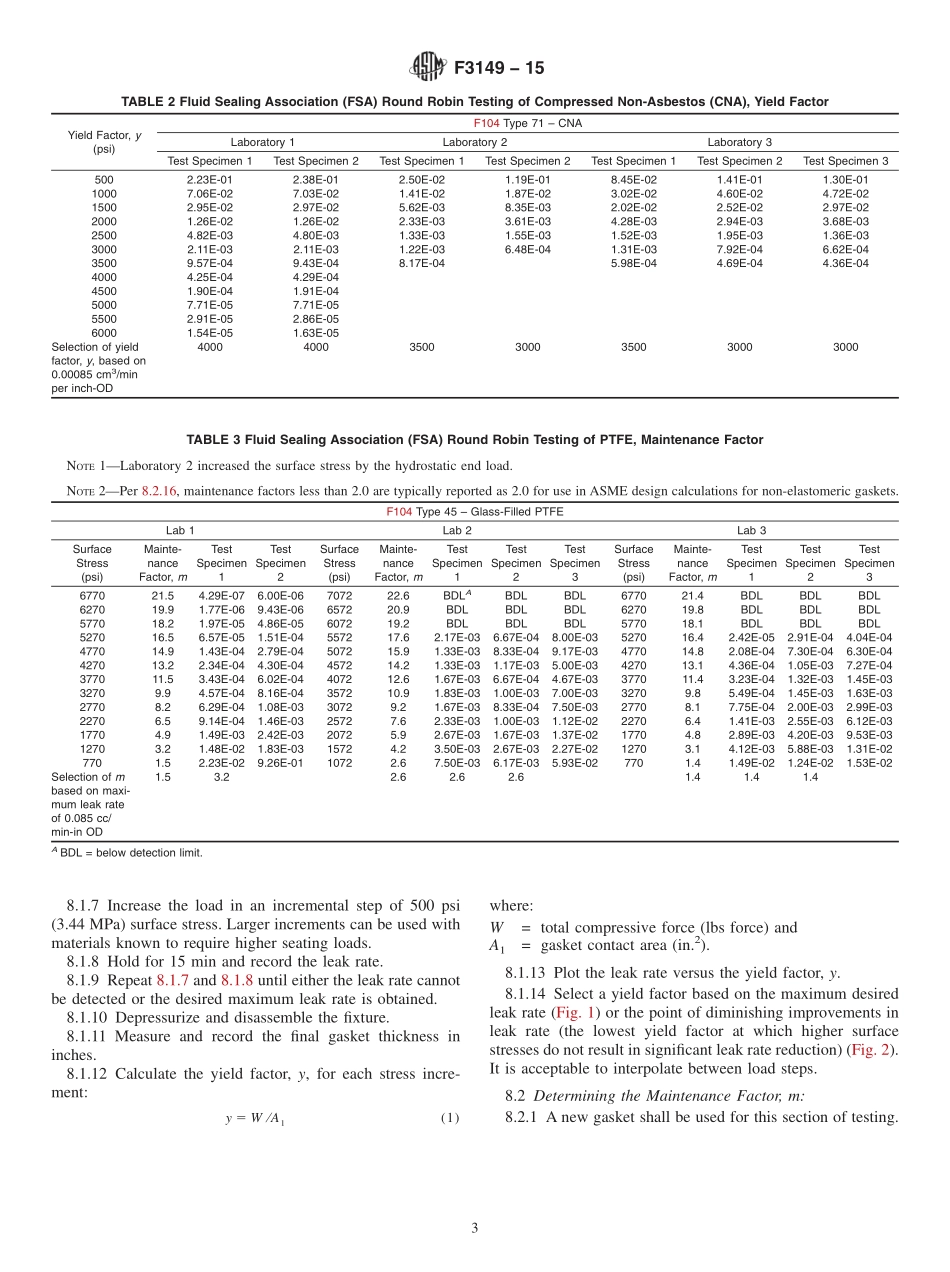

Designation:F3149−15StandardPracticeforDeterminingtheMaintenanceFactor(m)andYieldFactor(y)LoadingConstantsApplicabletoGasketMaterialsandDesigns1ThisstandardisissuedunderthefixeddesignationF3149;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1ThispracticewillestablishcriteriafordeterminingloadingconstantsthatarereferencedintheAmericanSocietyofMechanicalEngineers(ASME)pressurevesseldesign(BoilerandPressureVesselCode,SectionVIII,Divs.1and2).Theseconstantsarespecifictothisdesigncriterionformetallic,semi-metallic,andnonmetallicgaskets.1.2Units—Thevaluesstatedininch-poundunitsaretoberegardedasthestandard.ThevaluesgiveninparenthesesaremathematicalconversionstoSIunitsthatareprovidedforinformationonlyandarenotconsideredstandard.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2D2000ClassificationSystemforRubberProductsinAuto-motiveApplicationsF104ClassificationSystemforNonmetallicGasketMateri-alsF868ClassificationforLaminatedCompositeGasketMate-rials2.2ASMEStandards:3B16.5PipeFlangesandFlangedFittings:NPS1/2throughNPS24Metric/InchStandardBoilerandPressureVesselCodeSectionVIII,Divs.1and2PCC-1GuidelinesforPressureBoundaryBoltedFlangeJointAssembly2.3DINStandard:DIN3535GasketsforGasSupply42.4FSAStandard:FSAG605:11StandardTestMethodforDetermining(m)and(y)LoadingConstantsApplicabletoGasketMaterialsandDesigns53.Terminology3.1Definitions:3.1.1gasketcontactarea,A1,n—gasketareaincontactwiththeflangesurfacesandunderload.3.1.1.1Discussion—ThegasketcontactareadescribedinthispracticecandeviatefromtheeffectiveareadescribedintheASMEpressureve...