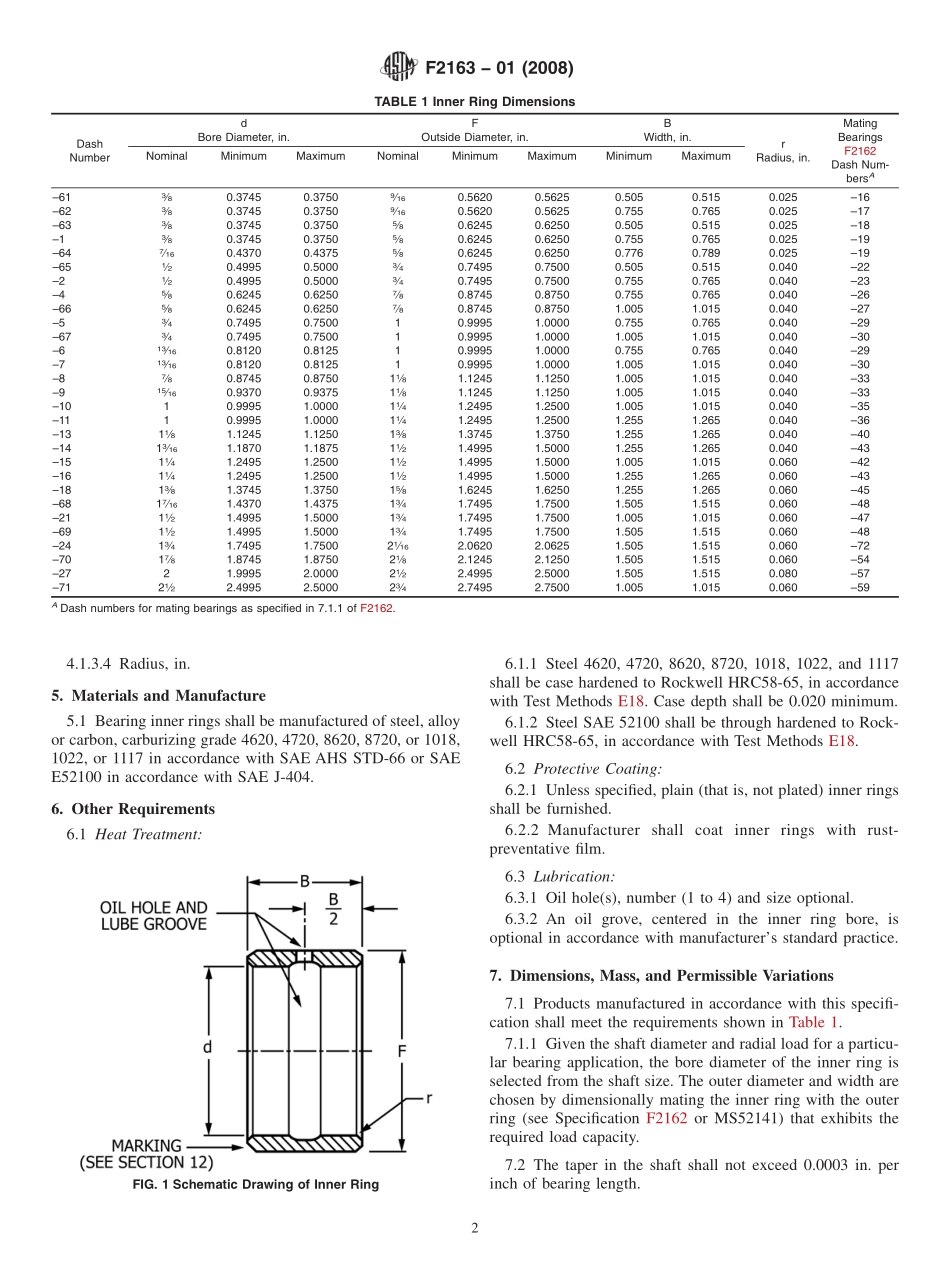

Designation:F2163−01(Reapproved2008)StandardSpecificationforRing,Bearing,Inner:forNeedleRollerBearingWithDrawnOuterRing1ThisstandardisissuedunderthefixeddesignationF2163;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheU.S.DepartmentofDefense.1.Scope1.1Thisspecificationcoversinnerringsforneedlerollerbearingswithdrawnouterrings.1.2Theinnerringsspecifiedinthisspecificationarein-tendedforuseonunhardenedshaftsinconjunctionwithopenendneedlerollerbearingsshownonSpecificationF2162andMS52141.1.3Theuseofrecycledmaterialsthatmeettherequirementsoftheapplicablematerialspecificationwithoutjeopardizingtheintendeduseoftheitemisencouraged.1.4Theinnerringsspecifiedinthisspecificationarenotintendedforuseinflight-criticalsystemsofaircraft.1.5Thevaluesstatedininch-poundunitsaretoberegardedasstandard.ThevaluesgiveninparenthesesaremathematicalconversionstoSIunitsthatareprovidedforinformationonlyandarenotconsideredstandard.NOTE1—ThisspecificationcontainsmanyoftherequirementsofMS17130,whichwasoriginallydevelopedbytheDepartmentofDefenseandiscurrentlymaintainedbytheDefenseSupplyCenterRichmond.2.ReferencedDocuments2.1ASTMStandards:2E18TestMethodsforRockwellHardnessofMetallicMa-terialsF2162SpecificationforBearing,Roller,Needle:DrawnOuterRing,FullComplement,WithoutInnerRing,OpenandClosedEnd,StandardType2.2ASMEStandard:ASMEB46.1SurfaceTextureSurfaceRoughness,Waviness,andLay32.3SAEStandards:SAEAHSSTD-664SAEJ-404ChemicalCompositionofSAEAlloySteels42.4MilitaryStandards:MIL-STD-130IdentificationMarkingofUSMilitaryProp-erty5MS52141Bearing,Roller,Needle:DrawnOuterRing,Caged,WithoutInnerRing,OpenandClosedEnd,Stan-dardType52.5AmericanBearingManufacturer’sAssociation(ABMA)Standard:STD4ToleranceDefinitionsandGaugingPracticesForBallandRollerBearings...