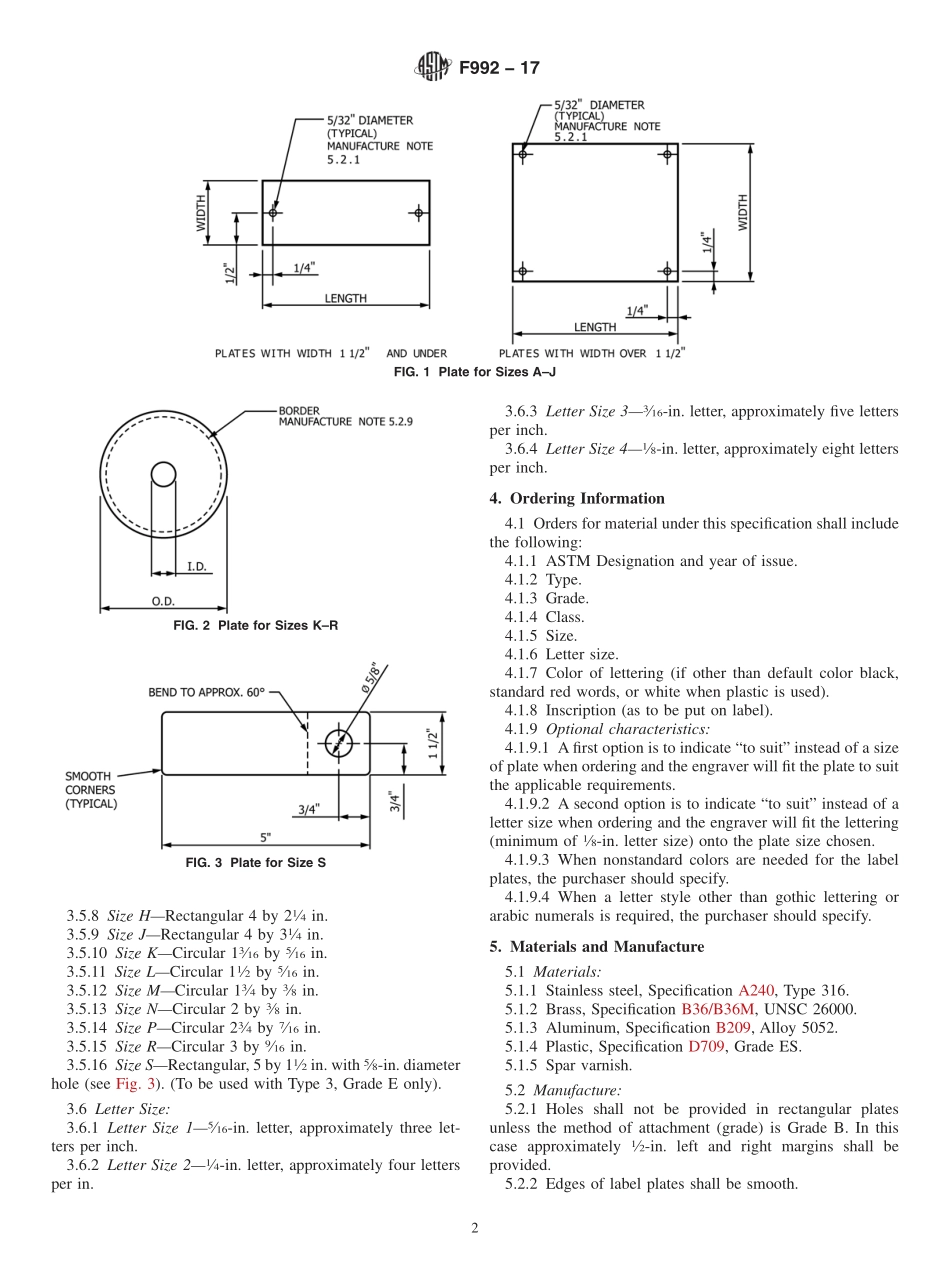

Designation:F992−17AnAmericanNationalStandardStandardSpecificationforValveLabelPlates1ThisstandardisissuedunderthefixeddesignationF992;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thisspecificationcoversthematerials,dimensions,inscription,andmethodsofinscribingforshipboardvalvelabelplates.1.2Fastenersshallbeorderedseparatelyandarenotin-cludedinthisspecification.1.3Thevaluesstatedininch-poundunitsaretoberegardedasstandard.Nootherunitsofmeasurementareincludedinthisstandard.1.4Thisinternationalstandardwasdevelopedinaccor-dancewithinternationallyrecognizedprinciplesonstandard-izationestablishedintheDecisiononPrinciplesfortheDevelopmentofInternationalStandards,GuidesandRecom-mendationsissuedbytheWorldTradeOrganizationTechnicalBarrierstoTrade(TBT)Committee.2.ReferencedDocuments2.1ASTMStandards:2A240SpecificationforChromiumandChromium-NickelStainlessSteelPlate,Sheet,andStripforPressureVesselsandforGeneralApplicationsB36/B36MSpecificationforBrassPlate,Sheet,Strip,AndRolledBarB209SpecificationforAluminumandAluminum-AlloySheetandPlateB580SpecificationforAnodicOxideCoatingsonAlumi-numD709SpecificationforLaminatedThermosettingMaterials2.2OtherDocuments:AmericanBureauofShippingRulesforBuildingandClassingSteelVessels3ANSIY14.38AbbreviationsandAcronymsforUseonDrawingsandRelatedDocuments43.Classification3.1Labelplatesshallbeclassifiedbytype,grade,class,size,andlettersizeinaccordancewithmaterialandmethodofinscribing,methodofattachment,thicknessofsheet,strip,orplate,dimensions,andlettersizetobeused.3.2TypesandMaterials:3.2.1TypeI—Anodizedaluminum,engraved.3.2.2TypeII—Anodizedaluminum,metalphoto.3.2.3TypeIII—Stainlesssteel,engraved.3.2.4TypeIV—Brass,engraved.3.2.5TypeV—Plastic,engraved.3.3GradesandMethodsofAttachment:3.3.1GradeA—Adhesiveonmetalbracket(backi...