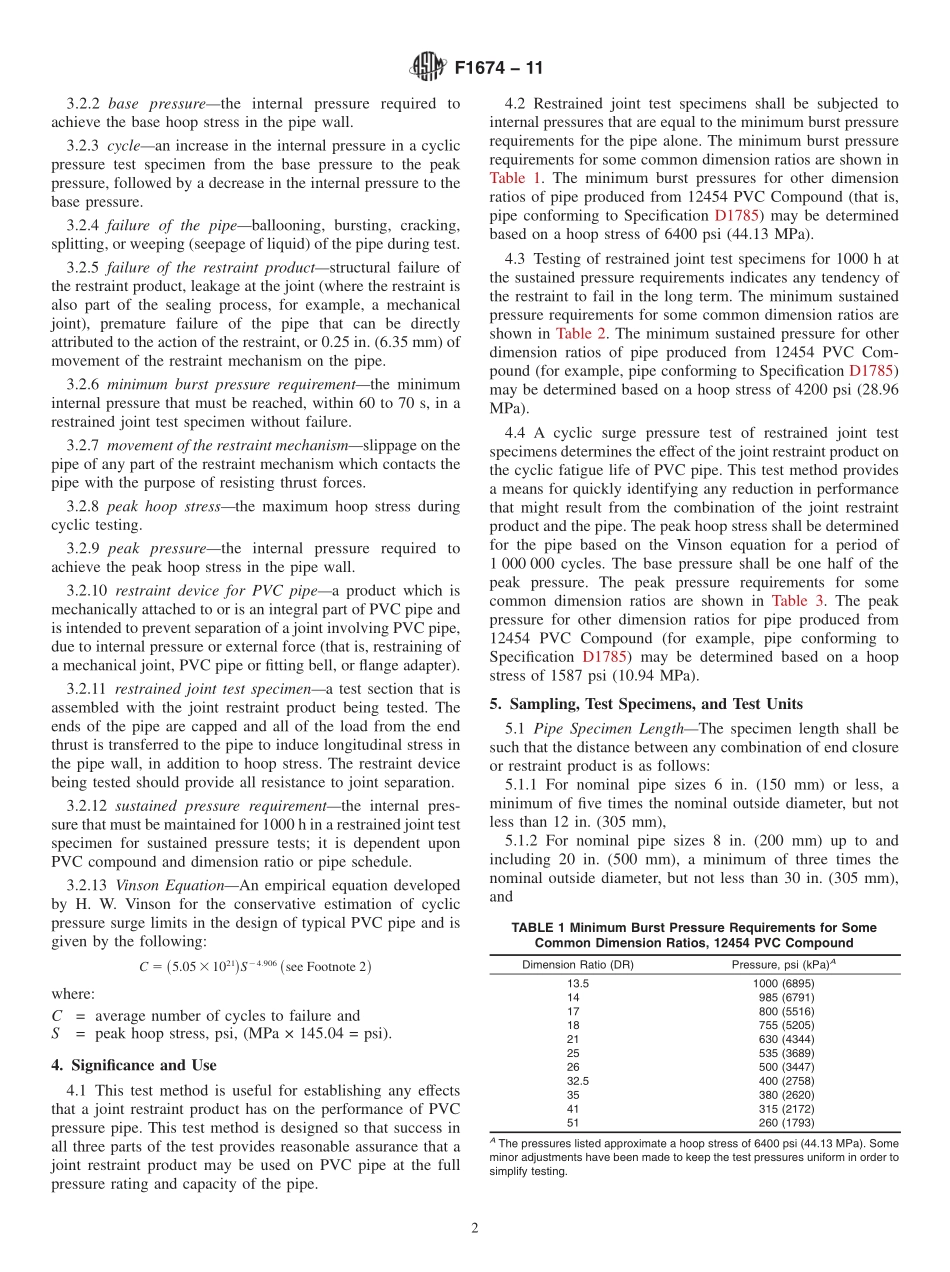

Designation:F1674−11StandardTestMethodforJointRestraintProductsforUsewithPVCPipe1ThisstandardisissuedunderthefixeddesignationF1674;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope*1.1ThistestmethoddescribesaprocedureforqualifyingtheperformanceofjointrestraintproductsforuseonPVCpressurepipesystemsbyevaluatingtheeffectofthejointrestraintproductontheperformancecharacteristicsofPVCpipeduringcyclicpressuretestsandstaticpressuretests.ThePVCpipepropertyvaluesreferencedinthistestmethodareforthe12454compoundasdescribedinSpecificationD1784anda4,000HDBshallbeobtainedbycategorizingtheLTHSinaccordancewithTable1inTestMethodD2837.Thatincludes,butisnotlimitedto,pipeproducedinaccordancewiththefollowingstandards:SpecificationsD1785andD2241,AWWAC900,andAWWAC905.1.2Thistestmethoddeterminestheshort-termperformanceofajointrestraintproductonPVCpipe,whichinvolvesthetestingofrestrainedjointtestsectionstotheminimumburstpressurerequirementsofthepipetodeterminequickburstperformance.1.3Thistestmethoddeterminesthelong-termeffectofajointrestraintproductonPVCpipe,whichinvolvesthetestingofrestrainedjointtestsectionstothesustainedpressurerequirementsofthepipeforaperiodof1000h.1.4ThistestmethodaddressesrestraintproductsthatareratedatthefullpressurecapacityofthePVCpipeonwhichtheyareused.Therearejointrestraintdevicesavailablethatarenotratedatthefullpressurecapacityofthepipe.Whilethoseproductshaveprovenacceptableandusefulinthemarketplace,thistestmethoddoesnotapplytothoseproducts.1.5ThistestmethoddeterminestheperformanceofajointrestraintproductonPVCpipesubjectedtocyclicpressuresurges.Theperformanceiscomparedtothebaselineperfor-manceofpipewithoutjointrestraintproductsestablishedbyHerbertW.Vinson.21.6Thevaluesstatedininch-poundunitsaretoberegardedasthestandard.Thevaluesinparenthesesareforin...