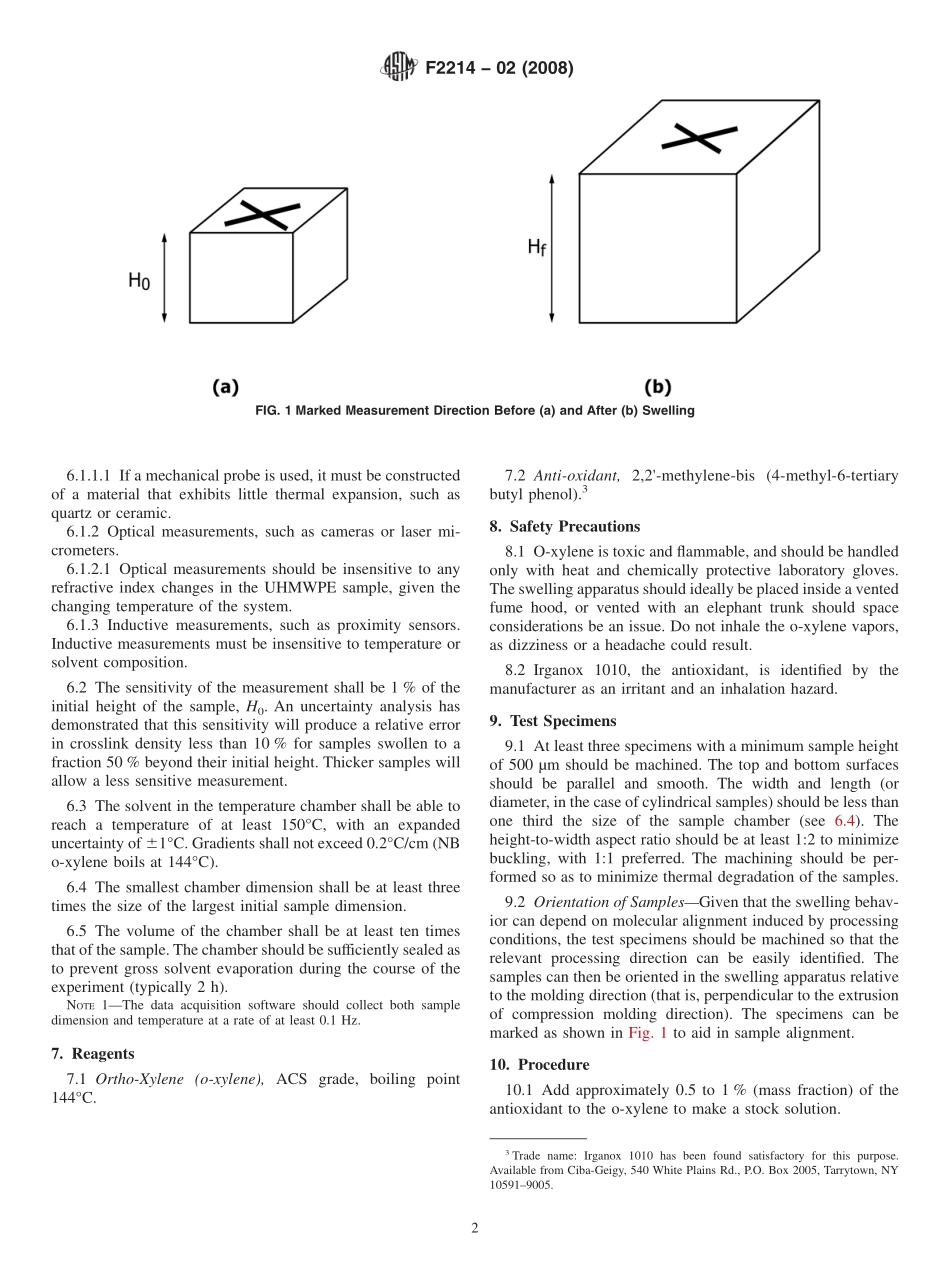

Designation:F2214−02(Reapproved2008)StandardTestMethodforInSituDeterminationofNetworkParametersofCrosslinkedUltraHighMolecularWeightPolyethylene(UHMWPE)1ThisstandardisissuedunderthefixeddesignationF2214;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethoddescribeshowthecrosslinkdensity,molecularweightbetweencrosslinks,andnumberofrepeatunitsbetweencrosslinksinultra-highmolecularweightpoly-ethylene(UHMWPE)crosslinkedbyionizingradiationorbychemicalmeanscanbedeterminedbymeasuringtheswellingratioofsamplesimmersedino-xylene.Examplesofexperi-mentaltechniquesusedtomakethesemeasurementsarediscussedherein.1.2Thetestmethodreportedheremeasuresthechangeinheightofasamplespecimenwhileitisimmersedinthesolvent.Volumetricswellratiosassumethatthesampleiscrosslinkedisotropically,andthatthechangeindimensionwillbeuniforminalldirections.Thistechniqueavoidsuncertaintyinducedbysolventevaporationortemperaturechange.1.3ThevaluesstatedinSIunitsaretoberegardedasstandard.Nootherunitsofmeasurementareincludedinthisstandard.1.4Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2D2765TestMethodsforDeterminationofGelContentandSwellRatioofCrosslinkedEthylenePlasticsE691PracticeforConductinganInterlaboratoryStudytoDeterminethePrecisionofaTestMethod3.Terminology3.1DefinitionsofTermsSpecifictoThisStandard:3.1.1crosslinkdensity,νd—thetheoreticalaveragenumberofcrosslinksperunitvolume[mol/dm3].3.1.2molecularweightbetweencrosslinks,Mc—thetheo-reticalaveragemolecularweightbetweencrosslinks[g/mol].3.1.3swellratio,qs—theratioofthevolumeofthesampleinanequili...