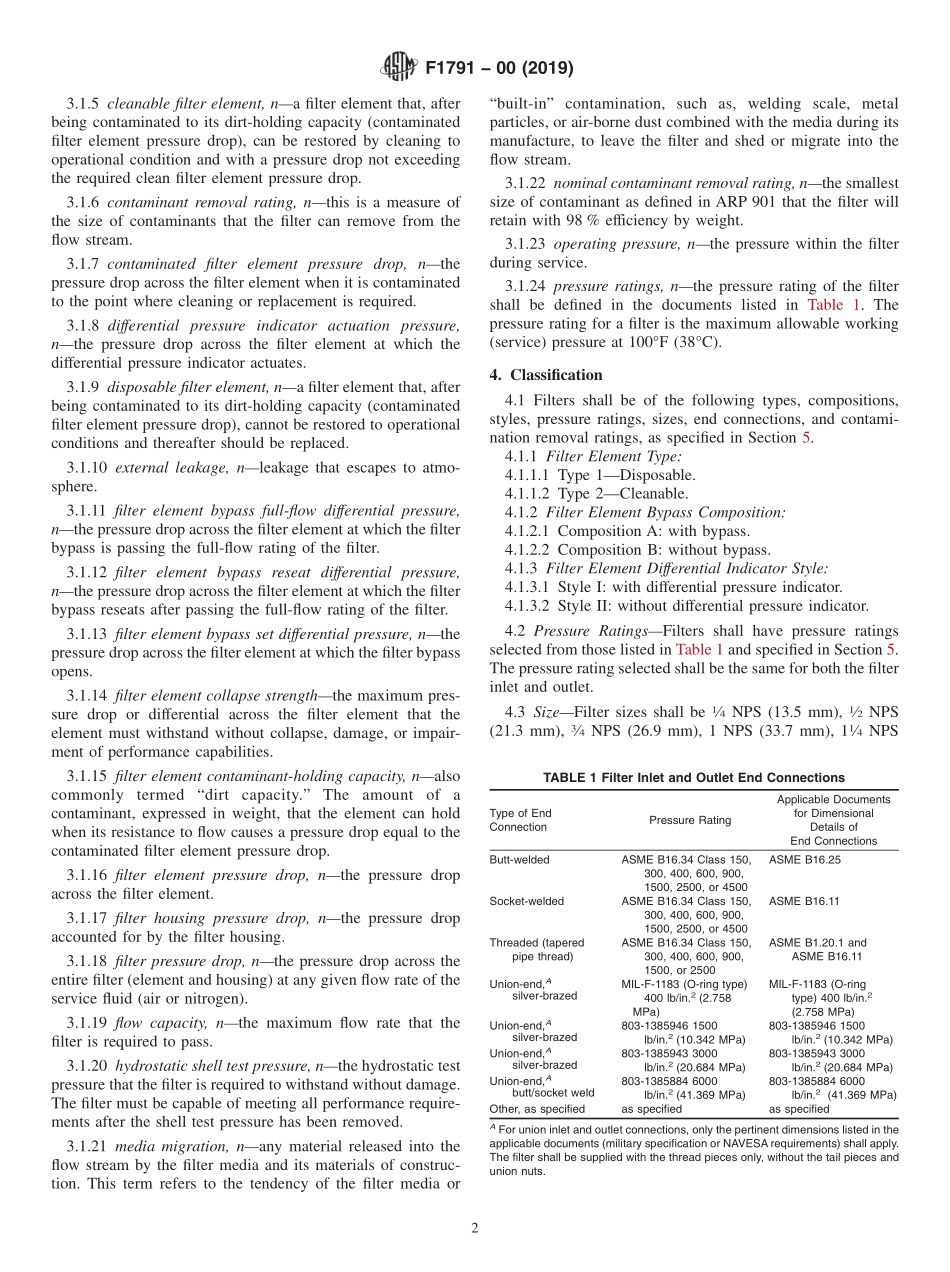

Designation:F1791−00(Reapproved2019)AnAmericanNationalStandardStandardSpecificationforFiltersUsedinAirorNitrogenSystems1ThisstandardisissuedunderthefixeddesignationF1791;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thisspecificationcoversthedesign,construction,test,andperformancerequirementsforairornitrogensystemfilters,referredtohereinafterasfilters.Thesefiltersareintendedtobeinstalledin-linetoprotectequipmentfromparticularcontami-nation.1.2ThevaluesstatedinSIunitsaretoberegardedasstandard.Thevaluesgiveninparenthesesaremathematicalconversionstoinch-poundunitsthatareprovidedforinforma-tiononlyandarenotconsideredstandard.1.3Thisinternationalstandardwasdevelopedinaccor-dancewithinternationallyrecognizedprinciplesonstandard-izationestablishedintheDecisiononPrinciplesfortheDevelopmentofInternationalStandards,GuidesandRecom-mendationsissuedbytheWorldTradeOrganizationTechnicalBarrierstoTrade(TBT)Committee.2.ReferencedDocuments2.1ASTMStandards:2F992SpecificationforValveLabelPlates2.2AmericanSocietyofMechanicalEngineers(ASME):3B1.1UnitedScrewThreads(UNandUNRThreadForm)B1.20.1PipeThreads,GeneralPurpose,InchB16.11ForgedFittings,Socket-WeldingandThreadedB16.25ButtweldingEndsB16.34ValvesFlanged,Threaded,andWeldingEnd2.3SocietyofAutomotiveEngineers(SAE):4ARP901AerospaceRecommendedPractice—Bubble-PointTestMethod2.4MilitaryStandardsandSpecifications:5MIL-STD-167-1MechanicalVibrationsofShipboardEquipment(TypeI—EnvironmentalandTypeII—InternallyExcited)MIL-STD-740-1AirborneSoundMeasurementsandAccep-tanceCriteriaofShipboardEquipmentMS16142Boss,GasketSealStraightThreadTubeFitting,StandardDimensionsforMIL-S-901ShockTests,H.I.(High-Impact);ShipboardMachinery,EquipmentandSystems,RequirementsforMIL-F-1183Fittings,Pipe,CastBronze,Silver-Brazing,GeneralSpecifications...