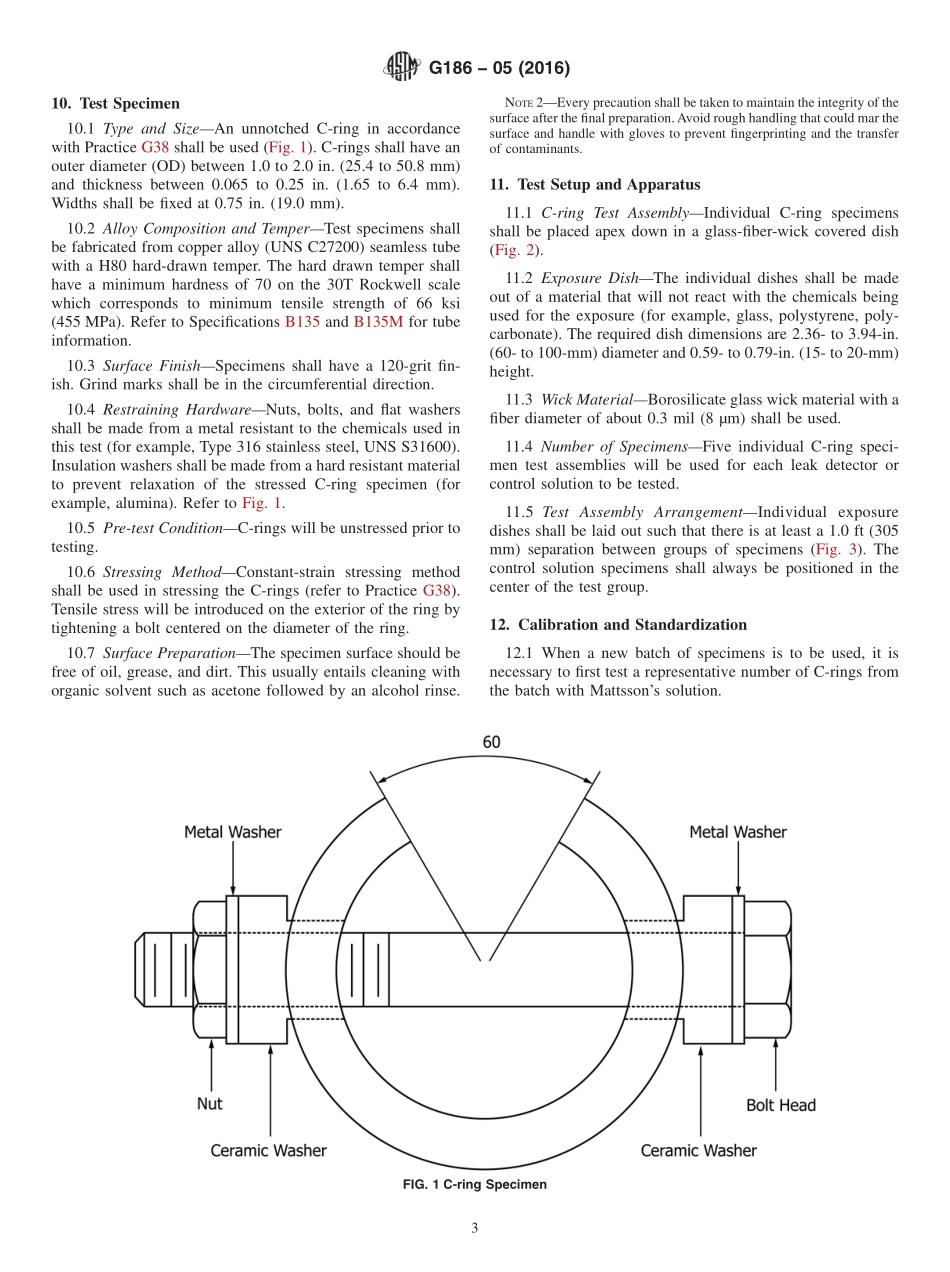

Designation:G186−05(Reapproved2016)StandardTestMethodforDeterminingWhetherGas-Leak-DetectorFluidSolutionsCanCauseStressCorrosionCrackingofBrassAlloys1ThisstandardisissuedunderthefixeddesignationG186;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethodcoversanacceleratedtestmethodforevaluatingthetendencyofgasleakdetectionfluids(LDFs)tocausestresscorrosioncracking(SCC)ofbrasscomponentsincompressedgasservice.1.2Thevaluesstatedininch-poundunitsaretoberegardedasstandard.ThevaluesgiveninparenthesesaremathematicalconversionstoSIunitsthatareprovidedforinformationonlyandarenotconsideredstandard.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesandtodeterminetheapplicabilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2B135SpecificationforSeamlessBrassTubeB135MSpecificationforSeamlessBrassTube[Metric]D1193SpecificationforReagentWaterG1PracticeforPreparing,Cleaning,andEvaluatingCorro-sionTestSpecimensG15TerminologyRelatingtoCorrosionandCorrosionTest-ing(Withdrawn2010)3G37PracticeforUseofMattsson’sSolutionofpH7.2toEvaluatetheStress-CorrosionCrackingSusceptibilityofCopper-ZincAlloysG38PracticeforMakingandUsingC-RingStress-CorrosionTestSpecimens3.Terminology3.1DefinitionsofTermsSpecifictoThisStandard:3.1.1GasLeakDetectorSolutions—Alsoknownasleakdetectionfluids,leakdetectorsolutions,bubblesolutions,andsoapsolutions,designatedinthisstandardasLDFs,arefluidsusedtodetectleaksinpressurizedgassystemsbytheforma-tionofbubblesattheleaksite.3.1.2Theterminologyusedherein,ifnotspecificallyde-finedotherwise,shallbeinaccordancewithTerminologyG15.4.SummaryofTestMethod4.1Thistestmethodconsistsofthreesteps:Thefirs...