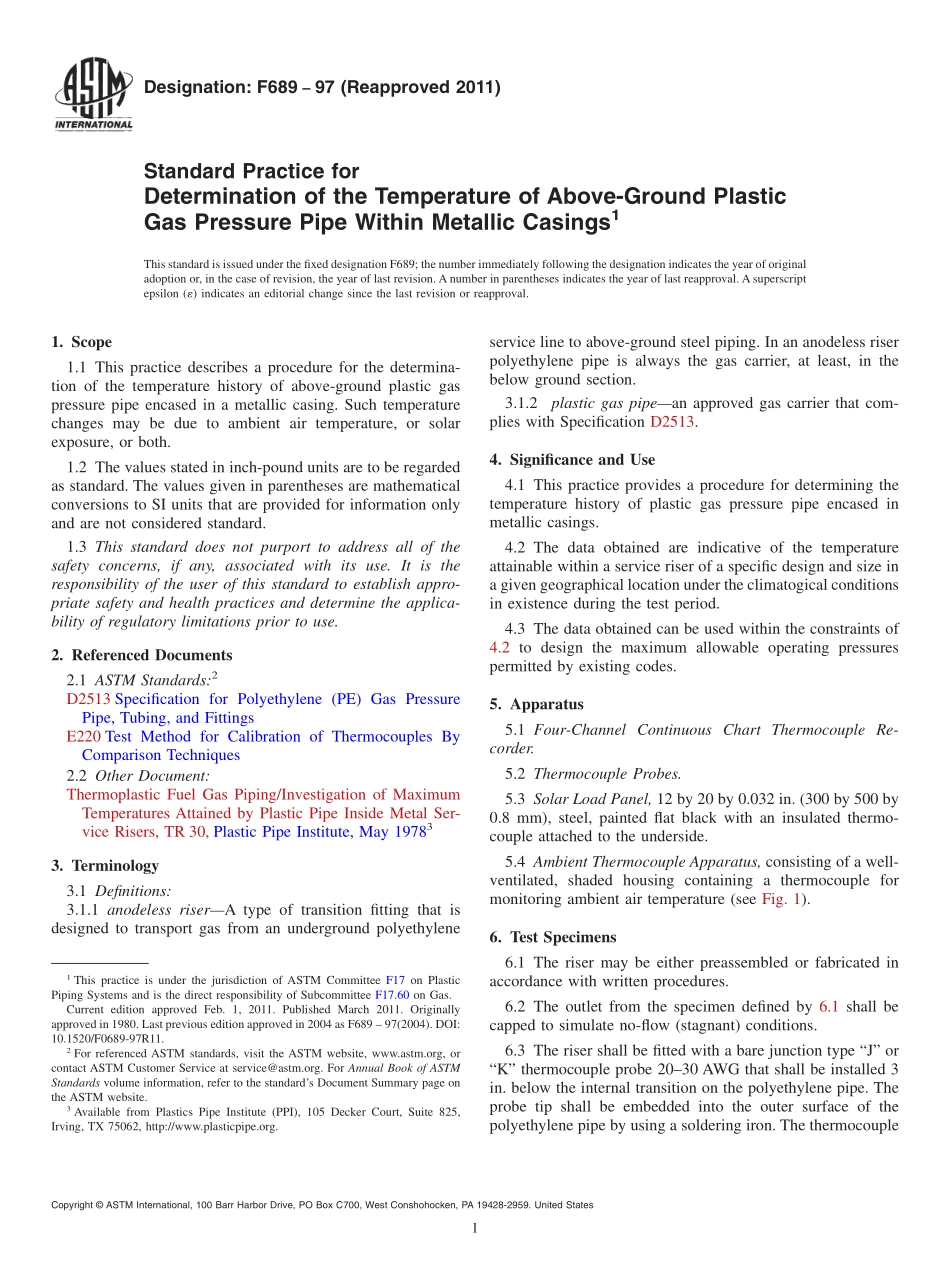

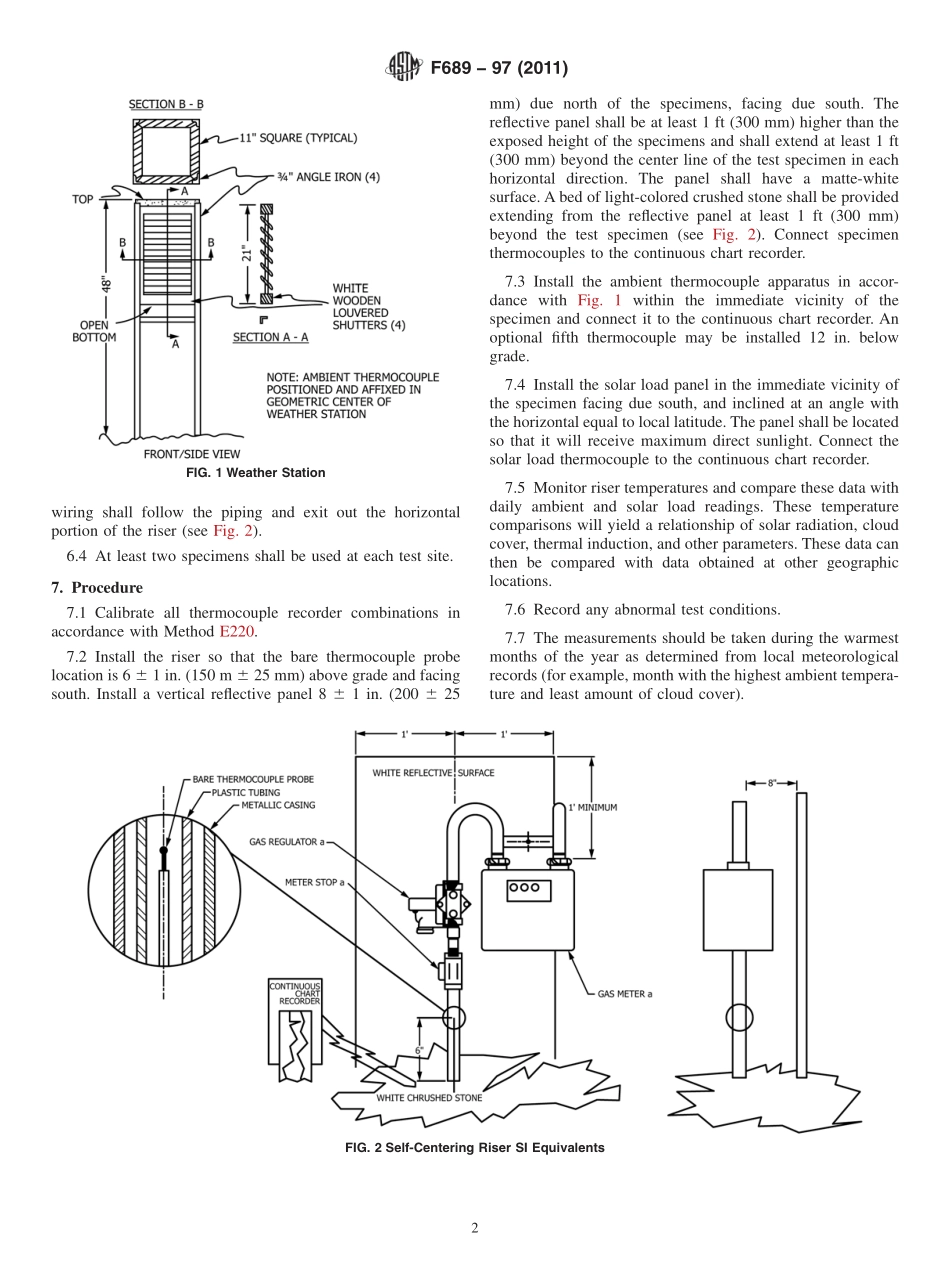

Designation:F689−97(Reapproved2011)StandardPracticeforDeterminationoftheTemperatureofAbove-GroundPlasticGasPressurePipeWithinMetallicCasings1ThisstandardisissuedunderthefixeddesignationF689;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thispracticedescribesaprocedureforthedetermina-tionofthetemperaturehistoryofabove-groundplasticgaspressurepipeencasedinametalliccasing.Suchtemperaturechangesmaybeduetoambientairtemperature,orsolarexposure,orboth.1.2Thevaluesstatedininch-poundunitsaretoberegardedasstandard.ThevaluesgiveninparenthesesaremathematicalconversionstoSIunitsthatareprovidedforinformationonlyandarenotconsideredstandard.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2D2513SpecificationforPolyethylene(PE)GasPressurePipe,Tubing,andFittingsE220TestMethodforCalibrationofThermocouplesByComparisonTechniques2.2OtherDocument:ThermoplasticFuelGasPiping/InvestigationofMaximumTemperaturesAttainedbyPlasticPipeInsideMetalSer-viceRisers,TR30,PlasticPipeInstitute,May197833.Terminology3.1Definitions:3.1.1anodelessriser—Atypeoftransitionfittingthatisdesignedtotransportgasfromanundergroundpolyethyleneservicelinetoabove-groundsteelpiping.Inananodelessriserpolyethylenepipeisalwaysthegascarrier,atleast,inthebelowgroundsection.3.1.2plasticgaspipe—anapprovedgascarrierthatcom-plieswithSpecificationD2513.4.SignificanceandUse4.1Thispracticeprovidesaprocedurefordeterminingthetemperaturehistoryofplasticgaspressurepipeencasedinmetalliccasings.4.2Thedataobtainedareindicativeofthetemperatureattainablewithinaserviceriserofaspecificdesignandsi...