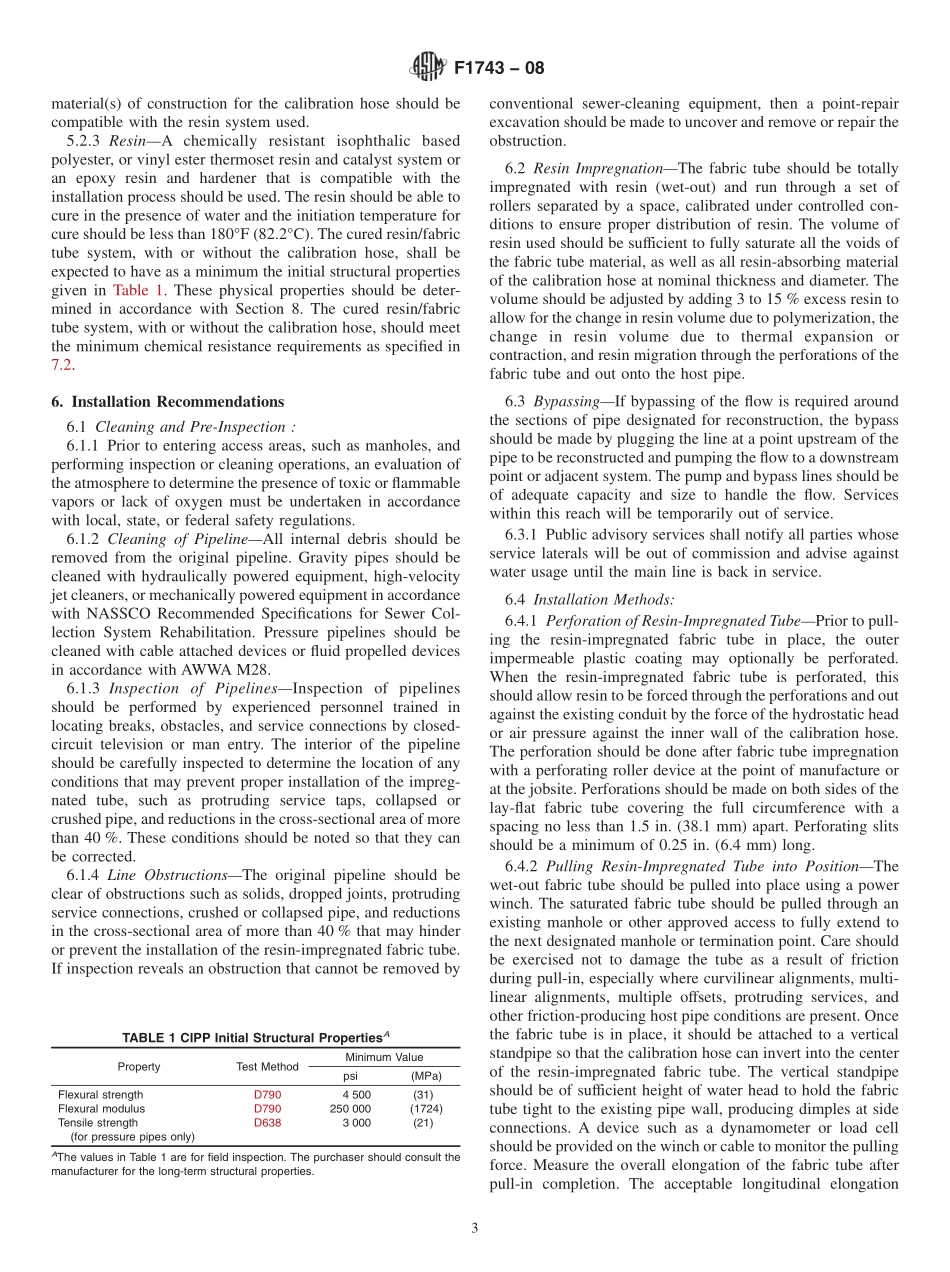

Designation:F1743−08StandardPracticeforRehabilitationofExistingPipelinesandConduitsbyPulled-in-PlaceInstallationofCured-in-PlaceThermosettingResinPipe(CIPP)1ThisstandardisissuedunderthefixeddesignationF1743;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope*1.1Thispracticedescribestheproceduresfortherecon-structionofpipelinesandconduits(4to96in.(10to244cm)diameter)bythepulled-in-placeinstallationofaresin-impregnated,flexiblefabrictubeintoanexistingconduitandsecondarilyinflatedthroughtheinversionofacalibrationhosebytheuseofahydrostaticheadorairpressure(seeFig.1).Theresiniscuredbycirculatinghotwaterorbytheintroductionofcontrolledsteamintothetube.Whencured,thefinishedcured-in-placepipewillbecontinuousandtightfitting.Thisreconstructionprocessmaybeusedinavarietyofgravityandpressureapplicationssuchassanitarysewers,stormsewers,processpiping,electricalconduits,andventilationsystems.1.2Thevaluesstatedininch-poundunitsaretoberegardedasstandard.ThevaluesgiveninparenthesesaremathematicalconversionstoSIunitsthatareprovidedforinformationonlyandarenotconsideredstandard.NOTE1—TherearenoISOstandardscoveringtheprimarysubjectmatterofthispractice.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2D543PracticesforEvaluatingtheResistanceofPlasticstoChemicalReagentsD638TestMethodforTensilePropertiesofPlasticsD790TestMethodsforFlexuralPropertiesofUnreinforcedandReinforcedPlasticsandElectricalInsulatingMateri-alsD903TestMethodforPeelorStrippingStrengthofAdhe-siveBondsD1600TerminologyforAbbreviatedTermsRelatingtoPlas-ticsD1682TestMethodforBreakingLoad...