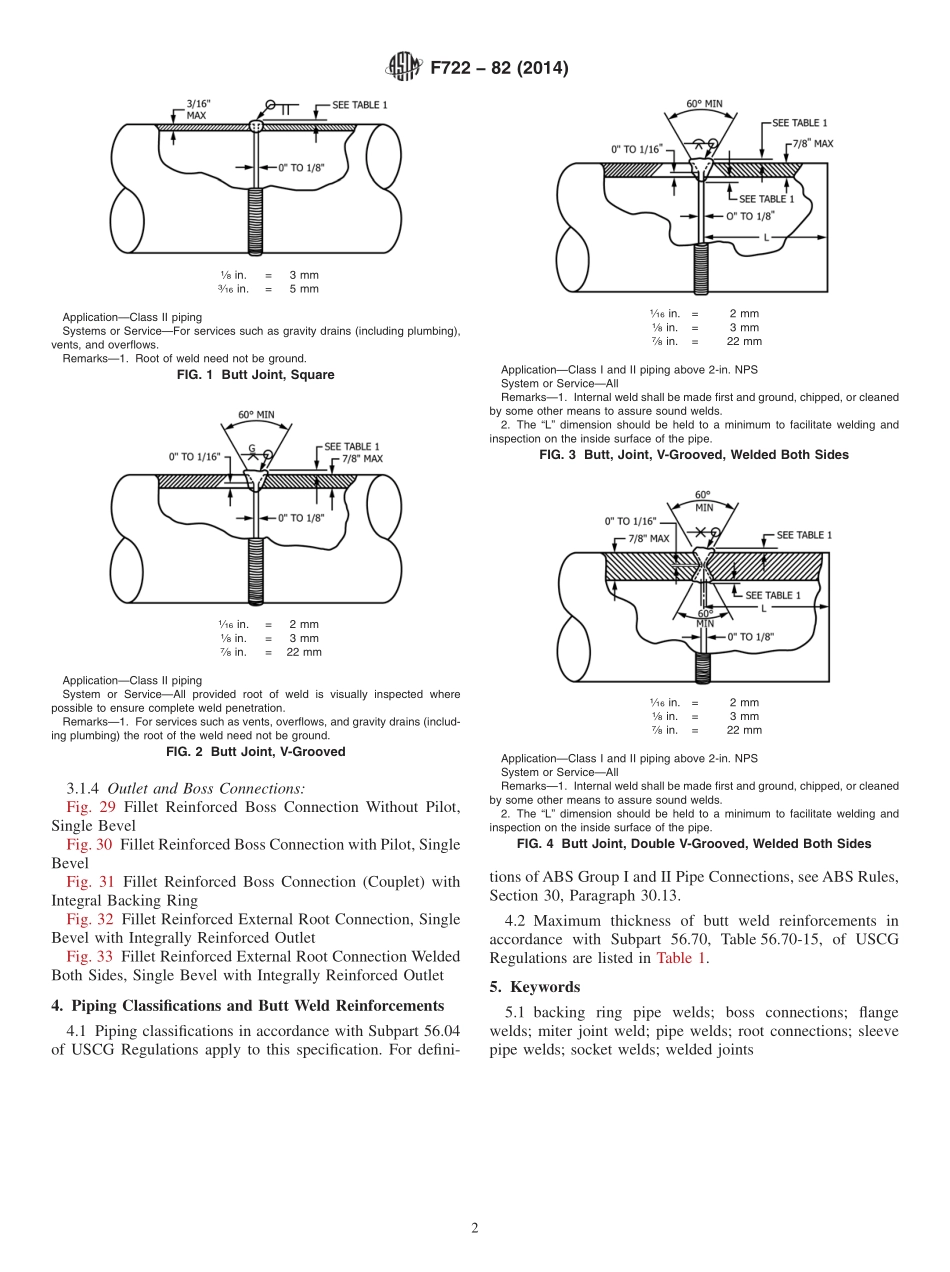

Designation:F722−82(Reapproved2014)AnAmericanNationalStandardStandardSpecificationforWeldedJointsforShipboardPipingSystems1ThisstandardisissuedunderthefixeddesignationF722;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thisspecificationcoverstypicaldetailsofweldedjointscommonlyusedinshipboardpipingsystems.Thesejointsandotherjointsmaybeusedprovidedtheweldingproceduresusedhavebeenqualifiedinaccordancewiththeapplicableregula-toryrulesandregulations.1.2Thevaluesstatedininch-poundunitsaretoberegardedasstandard.ThevaluesgiveninparenthesesaremathematicalconversionstoSIunitsthatareprovidedforinformationonlyandarenotconsideredstandard.2.ReferencedDocuments2.1FederalStandards:CodeofFederalRegulationsTitle46Shipping,Parts30to402CodeofFederalRegulationsTitle46Shipping,Parts41to692CodeofFederalRegulationsTitle46Shipping,Parts140to1492RulesforBuildingandClassingSteelVessels33.Application,Service,Limitations,andListofWeldJointDetails3.1Detailsofweldedjoints,includingapplication,service,andlimitationnotes,areprovidedintheappropriatefigures,asfollows:3.1.1Butt-WeldedJointsforPipes,Valves,Fittings,andFlanges:Fig.1ButtJoint,SquareFig.2ButtJoint,V-GroovedFig.3ButtJoint,V-Grooved,WeldedBothSidesFig.4ButtJoint,DoubleV-Grooved,WeldedBothSidesFig.5ButtJoint,CompoundBevelV-Grooved,WeldedBothSidesFig.6ButtJoint,V-Grooved,MiterTypeFig.7ButtJoint,V-Grooved,WeldedwithBevelEnd-TypeBackingRingFig.8ButtJoint,CompoundBevelV-Grooved,WeldedwithBevelEnd-TypeBackingRingFig.9ButtJoint,V-GroovedWeldedwithBevelEndLug-TypeBackingRingFig.10ButtJoint,V-Grooved,WeldedwithSquareEnd-TypeBackingRingFig.11ButtJoint,V-Grooved,WeldedwithConsumableInsertRingFig.12ButtJoint,CompoundBevelV-Grooved,WeldedwithConsumableInsertRingFig.13ButtJoint,U-Grooved,WeldedwithConsumableInsertRingFig.14ButtJoint,...