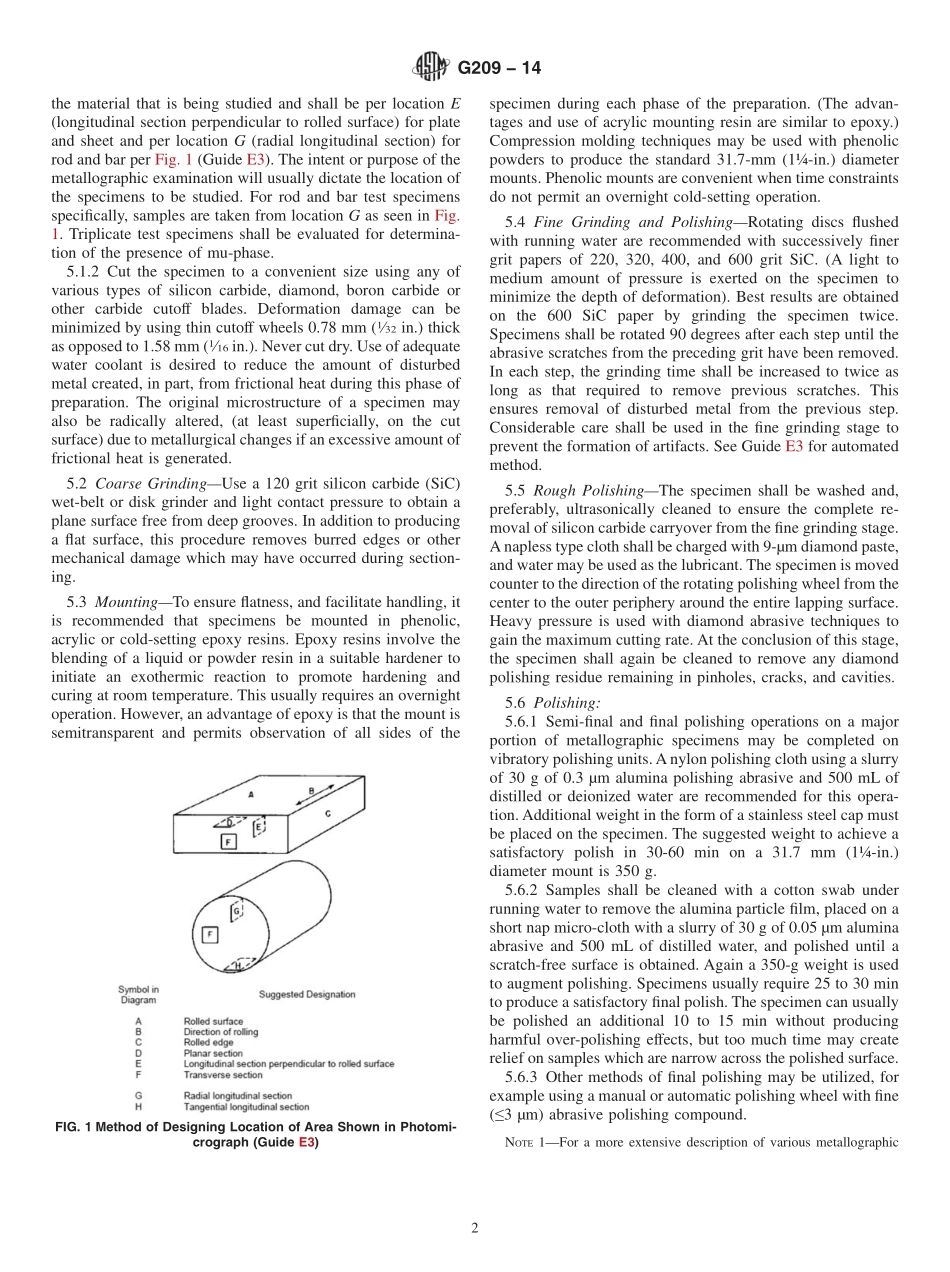

Designation:G209−14StandardPracticeforDetectingmu-phaseinWroughtNickel-Rich,Chromium,Molybdenum-BearingAlloys1ThisstandardisissuedunderthefixeddesignationG209;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1ThispracticeincorporatesetchingandmetallographicexaminationofWroughtNickel-Rich,Chromium,Molybdenum-BearingAlloyssuchas,butnotlimitedto,UNSN06686andUNSN10276.1.2Microstructureshaveastronginfluenceonpropertiesandsuccessfulapplicationofmetalsandalloys.Thepresenceofmu-phaseinthemicrostructuremaysignificantlyreducethecorrosionresistanceofWroughtNickel-Rich,Chromium,andMolybdenum-BearingAlloys.1.3Thispracticemaybeusedtodeterminethepresenceofmu-phaseinWroughtNickel-Rich,Chromium,andMolybdenum-BearingAlloysthroughcomparisonofmicro-structureobservedforetchedmetallographicspecimenstoaglossaryofphotomicrographsdisplayingthepresenceandabsenceofmu-phaseinthemicrostructure.1.4ThevaluesstatedinSIunitsaretoberegardedasthestandard.Otherunitsaregiveninparenthesesforinformationonly.1.5Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2D1193SpecificationforReagentWaterE3GuideforPreparationofMetallographicSpecimensE7TerminologyRelatingtoMetallographyE1245PracticeforDeterminingtheInclusionorSecond-PhaseConstituentContentofMetalsbyAutomaticImageAnalysisE1268PracticeforAssessingtheDegreeofBandingorOrientationofMicrostructuresG193TerminologyandAcronymsRelatingtoCorrosion3.Terminology3.1Definitions:3.1.1Theterminologyusedherein,ifnotspecificallyde-finedotherwise,shallbeinaccordancewithTerminologyG193.DefinitionsprovidedhereinandnotgiveninTerminol...