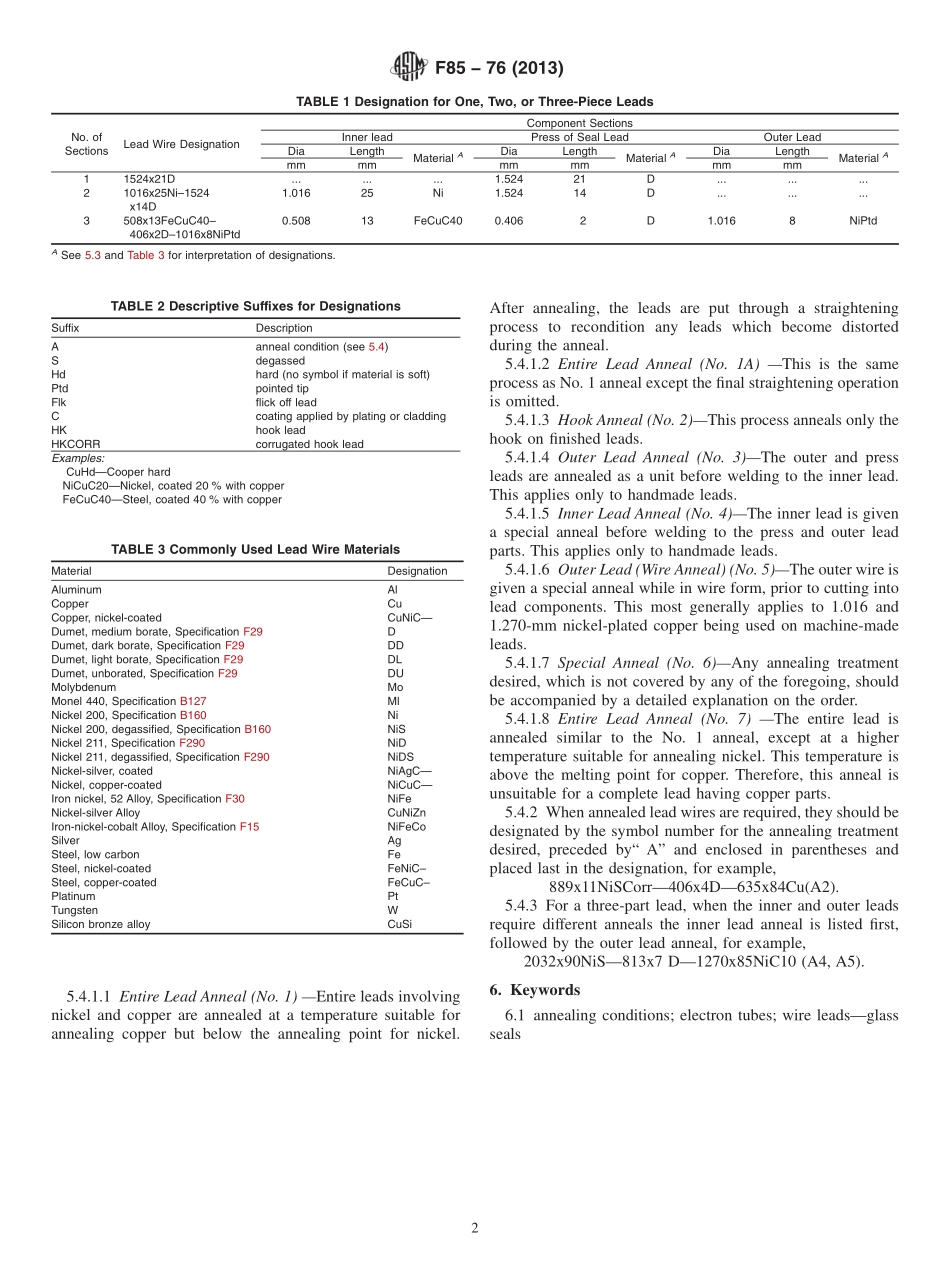

Designation:F85−76(Reapproved2013)StandardPracticeforNomenclatureforWireLeadsUsedasConductorsinElectronTubes1ThisstandardisissuedunderthefixeddesignationF85;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thispracticecoversrulesfordesignatingone,two,orthree-pieceroundwireleadsusedasconductorsthroughglasssealsinelectrontubes.Strandedleadsandleadsforsemicon-ductorsareexcluded.1.2ThevaluesstatedinSIunitsaretoberegardedasstandard.Nootherunitsofmeasurementareincludedinthisstandard.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2B127SpecificationforNickel-CopperAlloy(UNSN04400)Plate,Sheet,andStripB160SpecificationforNickelRodandBarF15SpecificationforIron-Nickel-CobaltSealingAlloyF29SpecificationforDumetWireforGlass-to-MetalSealApplicationsF30SpecificationforIron-NickelSealingAlloysF290SpecificationforRoundWireforWindingElectronTubeGridLaterals3.Dimensioning3.1Diameter—Thediametershallbeexpressedinmillime-tres.Threedigitsshallbeusedforalldiametersunder1mmandfourormoredigitsshallbeusedforalldiameters1mmandlarger.Adecimalpointisunderstoodtobepresentthreeplacesfromtheright.3.2Length—Thelengthshallbeexpressedinmillimetresusinganynumberofdigits.NOTE1—Allfractionsshallbeexpressedinmillimetresasdecimals.3.3Conventions—Thediametershallalwaysprecedeandbeseparatedfromthelengthbytheletter“x”.Forexample,awire13mmlongand0.508mmindiameterwillbereferredtoas508x13.4.Nomenclature4.1Thenomenclaturefordesignatingaleadshallconsistofone,two,orthreeparts;forone-,two-,orthree-pieceleads,respectively.Eachofthesepartsshallspecifyforitspiecethed...