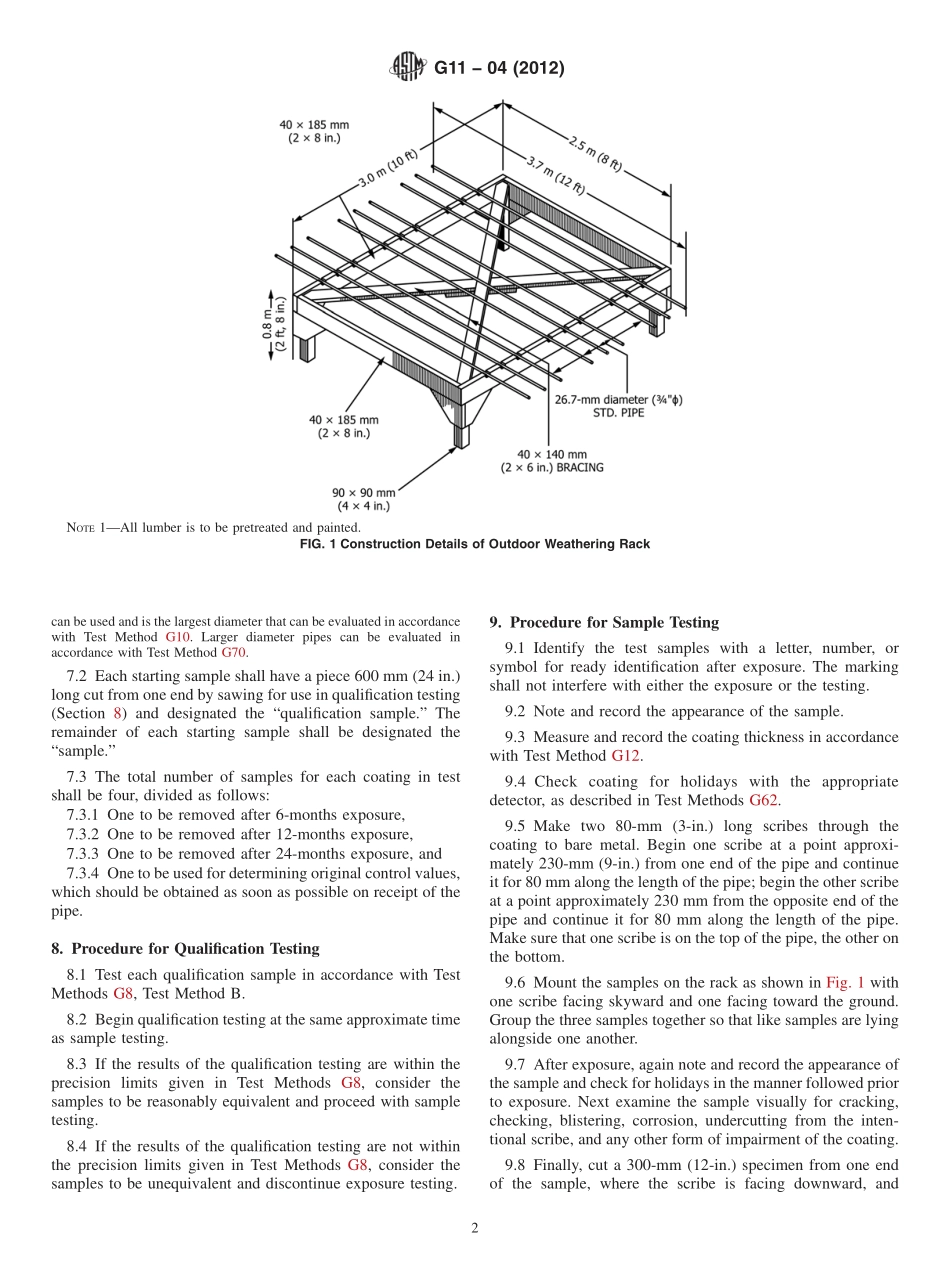

Designation:G11−04(Reapproved2012)StandardTestMethodforEffectsofOutdoorWeatheringonPipelineCoatings1ThisstandardisissuedunderthefixeddesignationG11;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethodisintendedtodefineconditionsfortheexposureofcoatedpipetoweather.1.2Thistestmethodspecifiesqualificationsforthesamples,proceduretobefollowedinexposuretoweather,andproce-dureforevaluatingeffectsofexposureincludingvisualexami-nationandothertests.1.3ThevaluesstatedinSIunitstothreesignificantdeci-malsaretoberegardedasthestandard.Thevaluesgiveninparenthesesareforinformationonly.1.4Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2G8TestMethodsforCathodicDisbondingofPipelineCoat-ingsG10TestMethodforSpecificBendabilityofPipelineCoat-ingsG12TestMethodforNondestructiveMeasurementofFilmThicknessofPipelineCoatingsonSteel(Withdrawn2013)3G14TestMethodforImpactResistanceofPipelineCoatings(FallingWeightTest)G62TestMethodsforHolidayDetectioninPipelineCoat-ingsG70TestMethodforRingBendabilityofPipelineCoatings(SqueezeTest)(Withdrawn2013)33.SummaryofTestMethod3.1Theeffectsofoutdoorweatheringonpipelinecoatingsafter6,12,and24months’exposurearedeterminedvisuallyandbyelectricalmeansbycomparingexposedsamplesofcoatedpipewithunexposedsamplesofcoatedpipebeforeandafterimpactandbendingtests.Atthebeginningofthetestthestartingsamplesarequalifiedbyacathodicdisbondingtest.4.SignificanceandUse4.1Sincecoatedpipemaybestoredoutdoorsforlongperiodsbeforeburial,weatheringtestsofthetypedescribedinthistestmethodareneededtoevaluatethestabilityofthesecoatingsst...