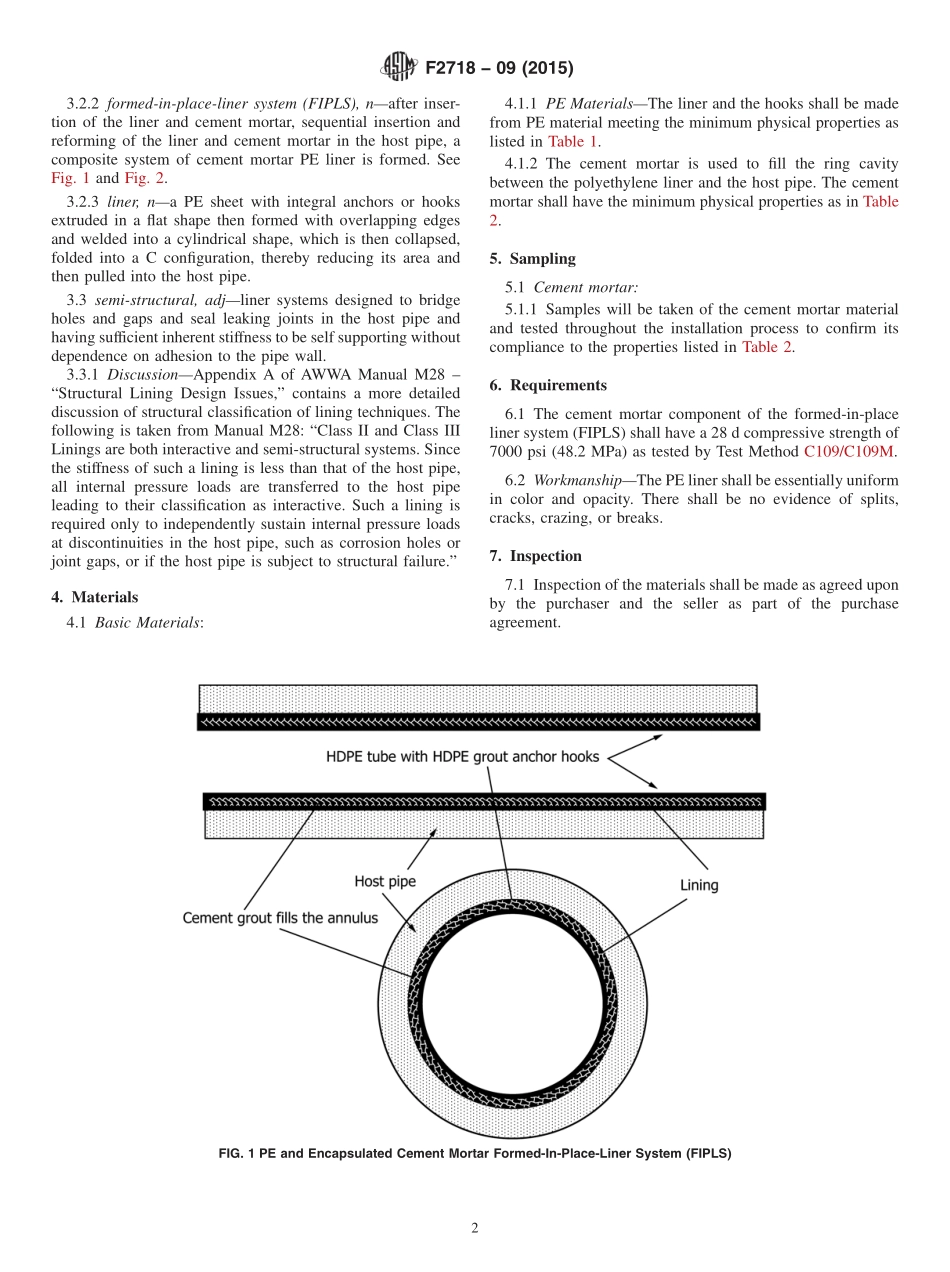

Designation:F2718−09(Reapproved2015)StandardSpecificationforPolyethylene(PE)andCementMaterialsforanEncapsulatedCementMortarFormedinPlaceLinerSystem(FIPLS)fortheRehabilitationofWaterPipelines1ThisstandardisissuedunderthefixeddesignationF2718;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thisspecificationcoversrequirementsandtestmethodsformaterialsforasemi-structuralpolyethylene(PE)encapsu-latedcementmortarformed-in-placelinersystem(FIPLS)intendedfortherehabilitationofwaterpipelinesofnominalsize4in.to12in.ThisrenewalprocessinvolvesinstallingacollapsedPEliner,foldedatthetimeofinsertion,intoanexistingpipeline,expandingthePEliner,andthenpumpingcementmortarintotheannulusbetweenthelinerandthemain.1.2Thelinerandcementmortarareprogressivelyroundedbymeansofanairpressurepropelledpigandexpandedagainsttheinteriorsurfaceoftheoriginalhostpipe.Afterrounding,thelineismaintainedunderpressureuntilthecementmortarcuresandthelineriscompletelyselfsupporting.1.3Thevaluesstatedininch-poundunitsaretoberegardedasstandard.ThevaluesgiveninparenthesesaremathematicalconversionstoSIunitsthatareprovidedforinformationonlyandarenotconsideredstandard.1.4Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.1.5ThereisnosimilarorequivalentISOstandard.2.ReferencedDocuments2.1ASTMStandards:2C109/C109MTestMethodforCompressiveStrengthofHydraulicCementMortars(Using2-in.or[50-mm]CubeSpecimens)D638TestMethodforTensilePropertiesofPlasticsD790TestMethodsforFlexuralPropertiesofUnreinforcedandReinforcedPlasticsandElectricalInsulatingMateri-alsD1505TestMethodforDensityofPlasticsbytheDensity-GradientTechniqueD1525...