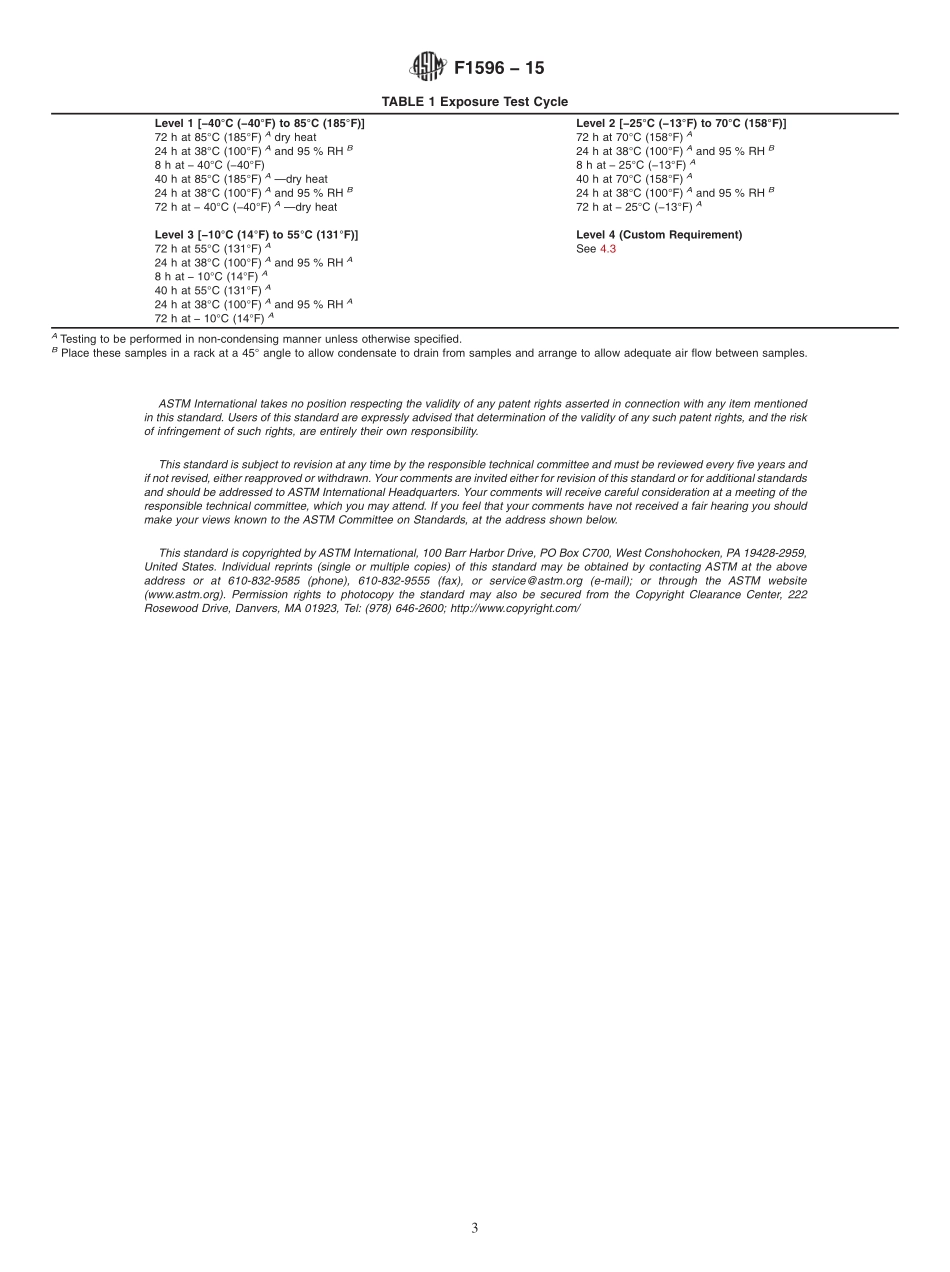

Designation:F1596−15StandardTestMethodforExposureofaMembraneSwitchorPrintedElectronicDevicetoTemperatureandRelativeHumidity1ThisstandardisissuedunderthefixeddesignationF1596;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethodcoversaprocedurefortemperatureandhumiditycyclingofamembraneswitchorprintedelectronicdevice.1.2Thistestmethodisperformedtoevaluatethepropertiesofmaterialsusedintheconstructionofmembraneswitchorprintedelectronicassembliesastheyareinfluencedbytheabsorptionanddiffusionofmoistureandmoisturevapor.Thisisanacceleratedenvironmentaltest,accomplishedbythecontinuousexposureofthetestspecimentohighrelativehumidityatanelevatedtemperature.Absorptionofmoisturebymanymaterialsresultsinswelling,whichdestroystheirfunc-tionalutility,causeslossofphysicalstrength,andchangesinothermechanicalproperties.Insulatingmaterialswhichabsorbmoisturemaysufferdegradationoftheirelectricalproperties.1.2.1Physicalchanges:1.2.1.1Differentialcontractionorexpansionratesorin-ducedstrainofdissimilarmaterials.1.2.1.2Crackingofsurfacecoatings.1.2.1.3Leakingofsealedcompartments.1.2.1.4Deformationorfractureofcomponents.1.2.2Chemicalchanges:1.2.2.1Separationofconstituents.1.2.2.2Failureofchemicalagentprotection.1.2.3Electricalchanges:1.2.3.1Changesinelectronicandelectricalcomponents.1.2.3.2Electronicormechanicalfailuresduetorapidwaterofcondensateformation.1.2.3.3Excessivestaticelectricity.1.3Thistestmethodisnotintendedtobeathermalshockprocedure;arampratebetweentemperatureextremesshouldnotexceed2°C/min.1.4Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1A...