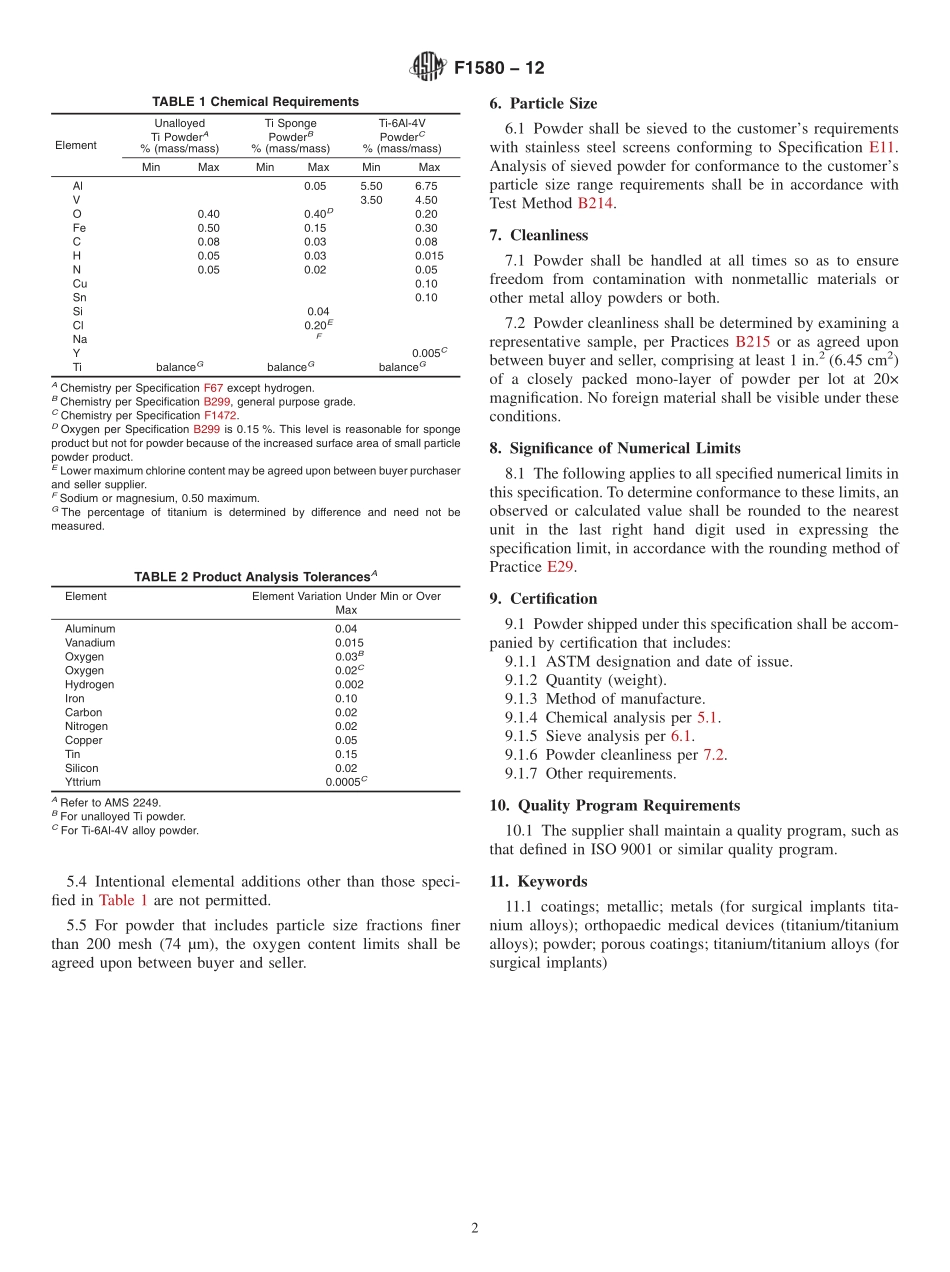

Designation:F1580−12StandardSpecificationforTitaniumandTitanium-6Aluminum-4VanadiumAlloyPowdersforCoatingsofSurgicalImplants1ThisstandardisissuedunderthefixeddesignationF1580;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope*1.1ThisspecificationcoverstherequirementsforunalloyedtitaniumandTi-6Al-4Valloypowdersforuseinfabricatingcoatingsontitaniumalloyimplants.1.2Powderscoveredunderthisspecificationmaybeusedtoformcoatingsbysinteringorthermalsprayingtechniques.1.3Thisspecificationcoverspowderrequirementsonly.Itdoesnotaddresspropertiesofthecoatingsformedfromthem.1.4Finelydividedtitaniumpowdermaybeconsideredpyrophoricandshouldbehandledinaccordancewiththeappropriateguidelines.1.5Thevaluesstatedininch-poundunitsaretoberegardedasstandard.ThevaluesgiveninparenthesesaremathematicalconversionstoSIunitsthatareprovidedforinformationonlyandarenotconsideredstandard.2.ReferencedDocuments2.1ASTMStandards:2B214TestMethodforSieveAnalysisofMetalPowdersB215PracticesforSamplingMetalPowdersB299SpecificationforTitaniumSpongeE11SpecificationforWovenWireTestSieveClothandTestSievesE29PracticeforUsingSignificantDigitsinTestDatatoDetermineConformancewithSpecificationsE2371TestMethodforAnalysisofTitaniumandTitaniumAlloysbyAtomicEmissionPlasmaSpectrometryF67SpecificationforUnalloyedTitanium,forSurgicalIm-plantApplications(UNSR50250,UNSR50400,UNSR50550,UNSR50700)F981PracticeforAssessmentofCompatibilityofBiomate-rialsforSurgicalImplantswithRespecttoEffectofMaterialsonMuscleandBoneF1472SpecificationforWroughtTitanium-6Aluminum-4VanadiumAlloyforSurgicalImplantApplications(UNSR56400)2.2ISOStandards:3ISO9001QualityManagementSystemRequirements2.3AerospaceMaterialSpecifications:4AMS2249ChemicalCheckAnalysisLimits,TitaniumandTitaniumAlloysAMS4998Powder,6Al-4V3.SignificanceandUse3.1Coatingsf...