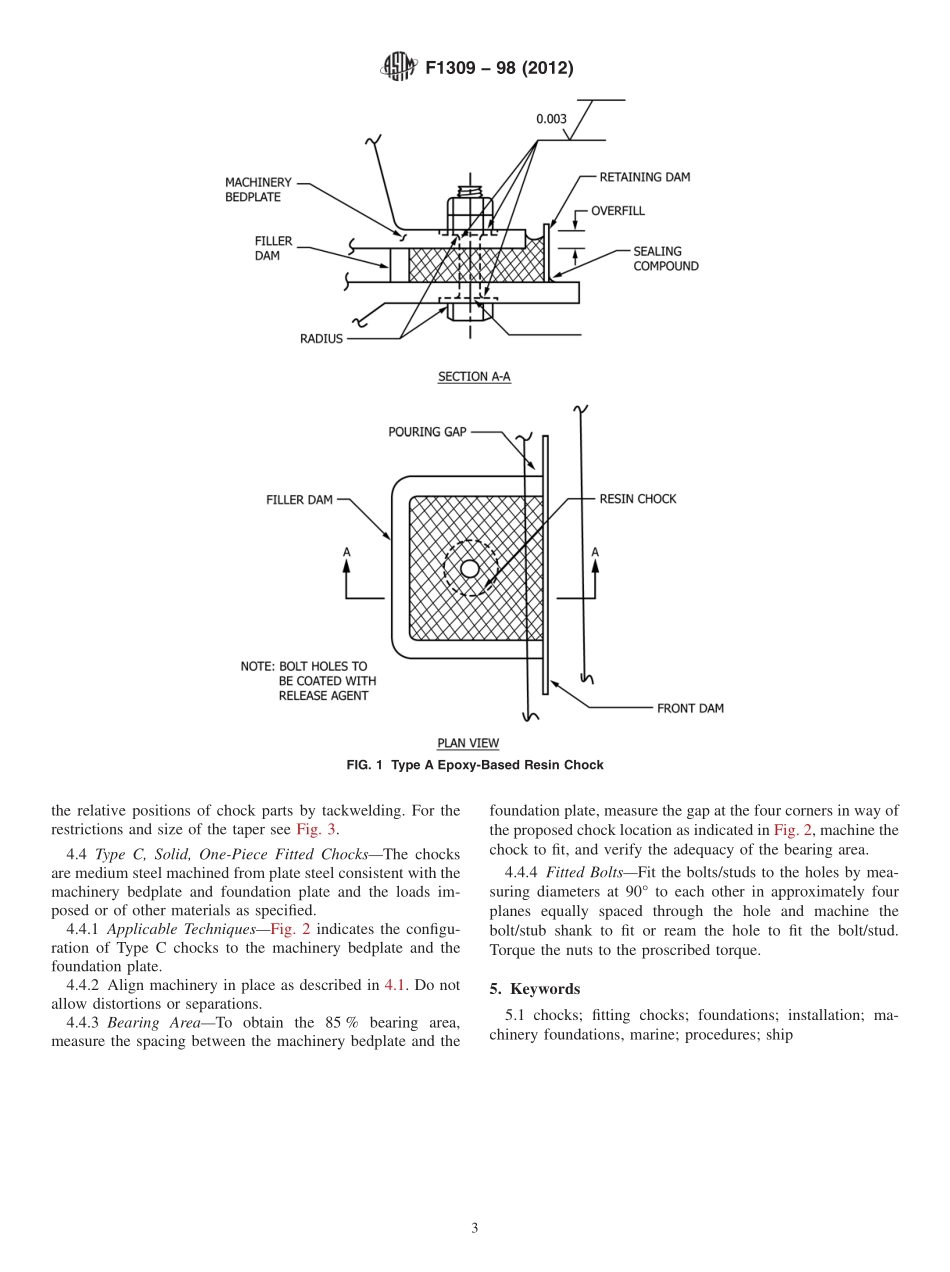

Designation:F1309−98(Reapproved2012)AnAmericanNationalStandardStandardPracticeforInstallationProceduresforFittingChockstoMarineMachineryFoundations1ThisstandardisissuedunderthefixeddesignationF1309;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thispracticecoverstheacceptablemethodsoffittingchockstomarinemachineryfoundations.1.2ThevaluesstatedinSIunitsshallberegardedasstandard.Thevaluesinparenthesesareforinformationonly.1.3Thisstandarddoesnotpurporttoaddressthesafetyconcernsassociatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappropriatesafetyandhealthpracticesanddeterminetheapplicabilityofregulatorylimita-tionspriortouse.2.ReferencedDocuments2.1ASTMStandards:2A370TestMethodsandDefinitionsforMechanicalTestingofSteelProductsD638TestMethodforTensilePropertiesofPlasticsD648TestMethodforDeflectionTemperatureofPlasticsUnderFlexuralLoadintheEdgewisePositionD695TestMethodforCompressivePropertiesofRigidPlastics2.2OtherDocuments:AmericanBureauofShippingRulesforBuildingandClassingSteelVessels3AmericanWeldingSocietyPublication,AWSD1.1Struc-turalWeldingCode43.SignificanceandUse3.1Thispracticeprovidesthethreeprincipalmethodsoffittingchockstomarinemachineryfoundationstoensurethatthemachineryisfreeofvibrationandperfectlyalignedafterinstallation.3.1.1Thethreeprincipalmethodsofinstallingchocksdescribedhereinareasfollows:3.1.1.1TypeA—Epoxy-basedresin,nonshrinkingChock-fastOrangePR610TCFbyPhiladelphiaResinCorp.,orequal,and3.1.1.2TypeB—Two-piecewedgechocks.3.1.1.3TypeC—Solid,one-piecefittedchocks.4.Procedure4.1GeneralRequirementsforTypesA,B,andCChockingSystems:4.1.1Machining:4.1.1.1TypeAchocks,machinerybedplates,foundationplates,andboltsdonotrequirefinishmachiningifthechocksarenotdesignedtoberemoved.Unlessspecifiedotherwise,TypesBandCchock,...