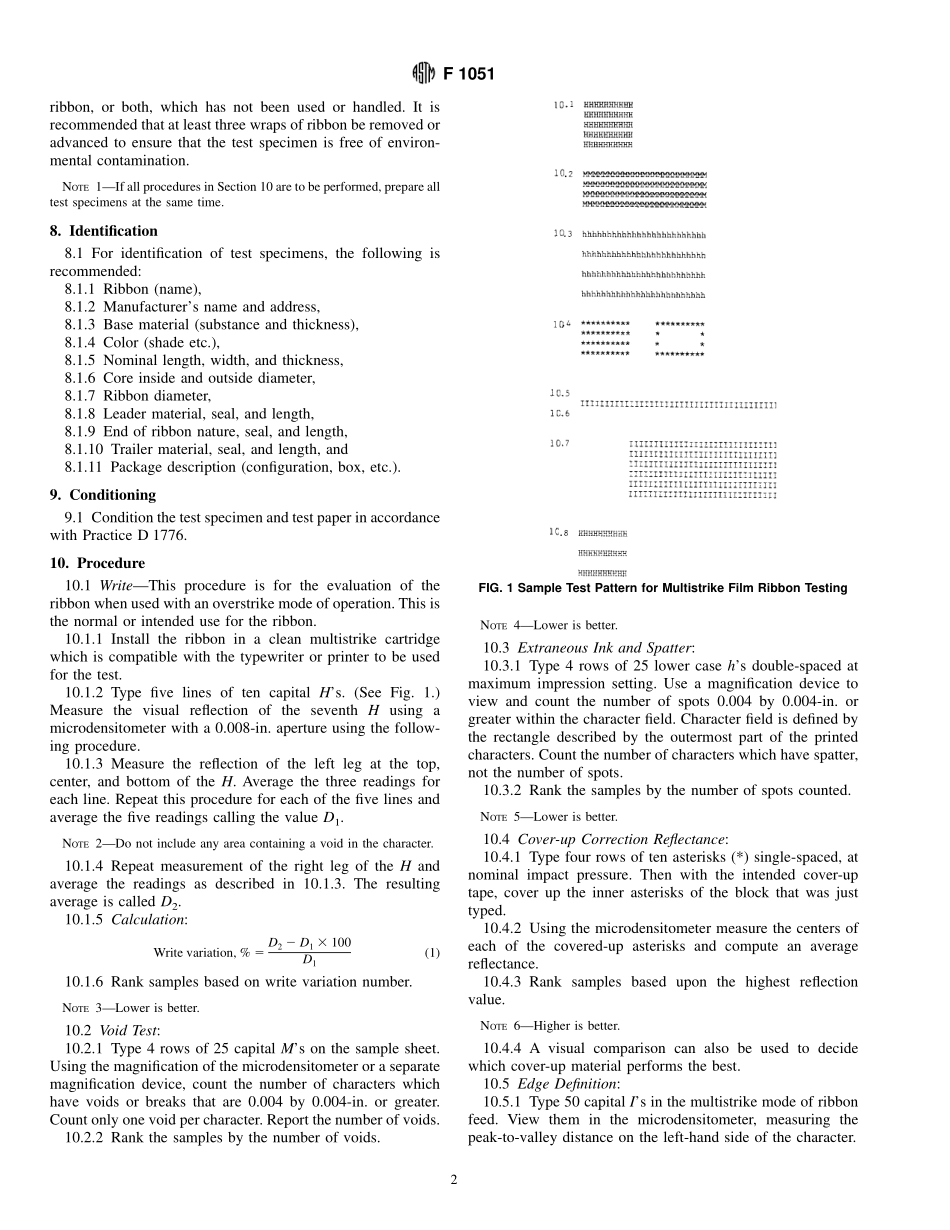

Designation:F1051–00StandardTestMethodforComparingMultistrikeFilmRibbons1ThisstandardisissuedunderthefixeddesignationF1051;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(e)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethodcoversinformationandtechniquesforevaluatingseveralperformancequalitiesofmultistrikefilmtypewriter/printerribbonsonacomparativebasisforgeneralofficeuse.Itisnotintendedforspecializedapplicationssuchasopticalcharacterrecognition.1.2Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.SeeNote10foraspecificcautionarystatement.2.ReferencedDocuments2.1ASTMStandards:D1776PracticeforConditioningTextilesforTesting2D3460SpecificationforWhiteWatermarkedandUnwater-markedBond,Mimeograph,Duplicator,andXerographicCut-SizedOfficePapers3F221TerminologyRelatingtoCarbonPaperandInkedRibbonProductsandImagesMadeTherefrom3F425TerminologyRelatingtoLithographicCopyProd-ucts3F497PracticeforUseoftheElectricandElectronicType-writerasaTestInstrument32.2ANSIStandards:PH2.17DensityMeasurements—GeometricConditionsforReflectionDensity4PH2.18DensityMeasurements—SpectralConditions43.Terminology3.1Fordefinitionsoftermsusedinthistestmethod,seeTerminologyF221andF425.4.SummaryofTestMethod4.1Thistestmethodconsistsoftestingmultistrikefilmribbonsunderactualandsimulateduseconditions,employingprinters,automatictypewriters,ortypewritersequippedwitharobotdeviceandseveralsimulationtechniquesgenerallyacceptedintheinkedribbonindustry.Allsampleribbonsareconditionedandtestedunderidenticalconditions,soastoobtaincomparativeresults.5.SignificanceandUse5.1Thistestmethodshouldbeusedtoevaluateseveralperformancequalitiesofmultistrikefilmrib...