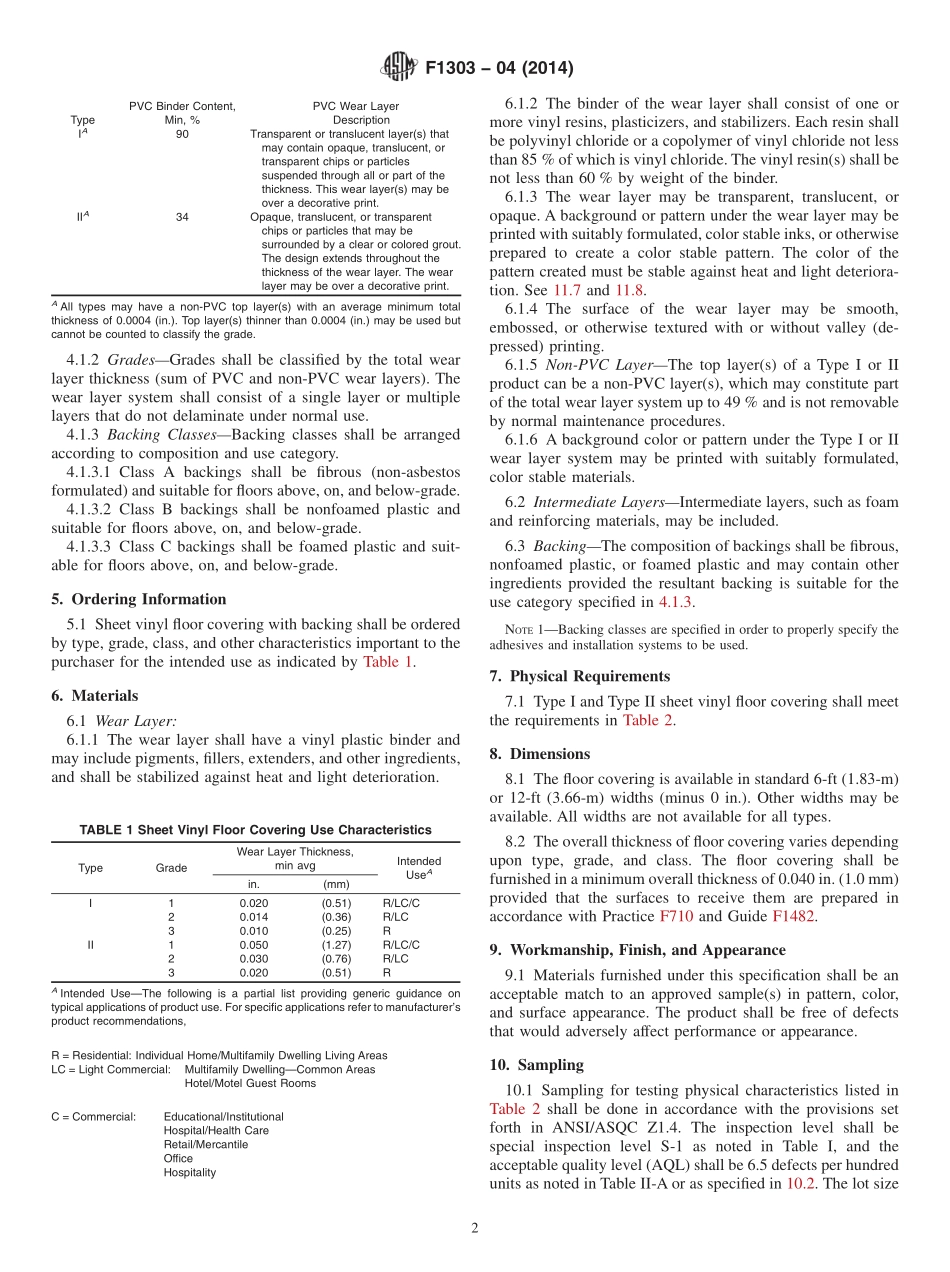

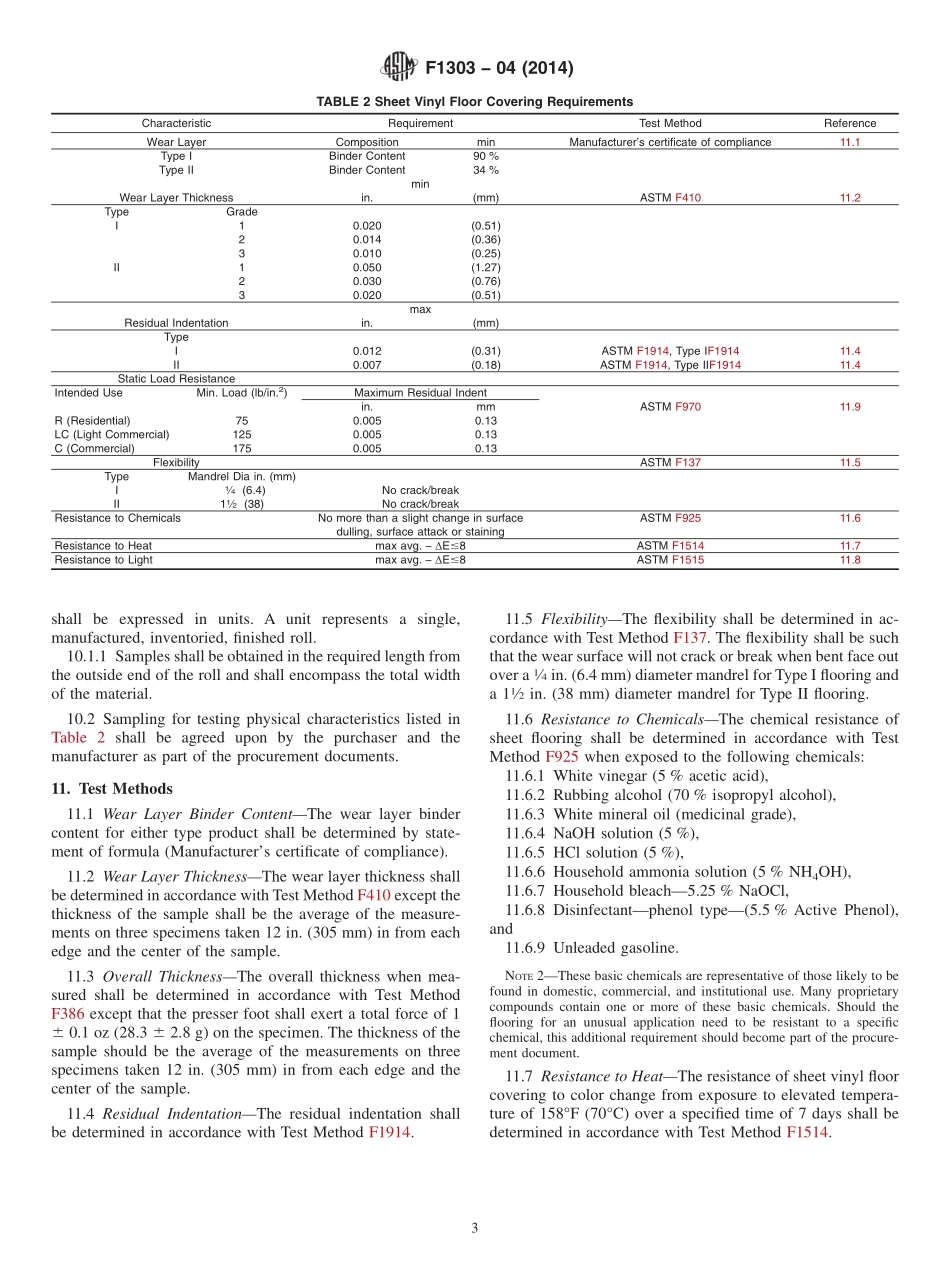

Designation:F1303−04(Reapproved2014)StandardSpecificationforSheetVinylFloorCoveringwithBacking1ThisstandardisissuedunderthefixeddesignationF1303;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thisspecificationcoversfloorcoveringhavingavinylplasticwearlayerwithbacking.Productsmayalsocontainnon-PVCspecialtyperformancetoplayer(s)orintermediatelayer(s),orboth.1.2Twotypesoffloorcoveringbasedonbindercontentarecovered.Thefloorcoveringisintendedforuseincommercial,lightcommercial,andresidentialbuildingsbasedonservice-abilitycharacteristics.Generalinformationandperformancecharacteristicsthatdetermineserviceabilityandrecommendeduseareincludedinthisspecification.1.3Thevaluesstatedininch-poundunitsaretoberegardedasstandard.ThevaluesgiveninparenthesesaremathematicalconversionstoSIunitsthatareprovidedforinformationonlyandarenotconsideredstandard.1.4Thefollowingsafetyhazardscaveatpertainsonlytothetestmethodsportion,Section11,ofthisspecification.Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappropriatesafetyandhealthpracticesanddeterminetheapplicabilityofregulatorylimita-tionspriortouse.2.ReferencedDocuments2.1ASTMStandards:2F137TestMethodforFlexibilityofResilientFlooringMa-terialswithCylindricalMandrelApparatusF141TerminologyRelatingtoResilientFloorCoveringsF386TestMethodforThicknessofResilientFlooringMa-terialsHavingFlatSurfacesF410TestMethodforWearLayerThicknessofResilientFloorCoveringsbyOpticalMeasurementF710PracticeforPreparingConcreteFloorstoReceiveResilientFlooringF925TestMethodforResistancetoChemicalsofResilientFlooringF970TestMethodforStaticLoadLimitF1482PracticeforInstallationandPreparationofPanelTypeUnderlaymentstoReceiveResilientFlooringF1514TestMethodforMeas...