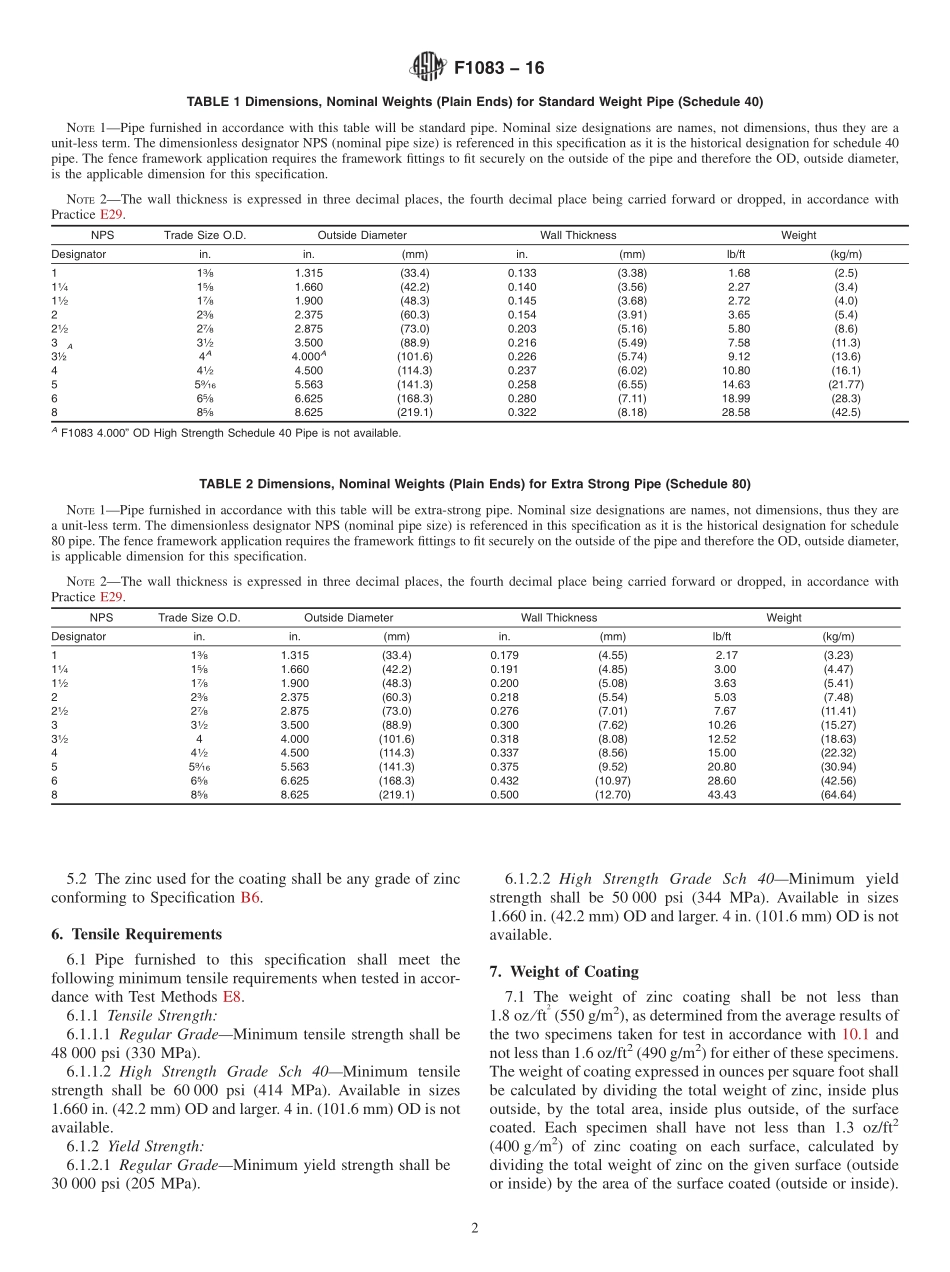

Designation:F1083−16StandardSpecificationforPipe,Steel,Hot-DippedZinc-Coated(Galvanized)Welded,forFenceStructures1ThisstandardisissuedunderthefixeddesignationF1083;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheU.S.DepartmentofDefense.1.Scope1.1Thisspecificationcovershot-dippedgalvanizedweldedsteelpipeinsizesrangingfrom1.315–8.625in.(33.4–219.1mm)outsidediameter(OD)inclusive,withnominal(average)wallthicknessasgiveninTable1andTable2.Pipehavingotherdimensions(Note2)maybefurnishedprovidedsuchpipecomplieswithallotherrequirementsofthisspecifi-cation.PipeorderedunderthisspecificationisintendedforuseasastructuralsupportforfencinginaccordancewithSpecifi-cationF1043,Group1A.NOTE1—Outsidediametersizeisdesignatedinthatfencefittingsaredesignedtosecurelyfitontheoutsideofthepipeframework.NOTE2—AcomprehensivelistingofstandardizedpipedimensionsiscontainedinANSIB36.10.1.2Thevaluesstatedininch-poundunitsaretoberegardedasthestandard.Thevaluesgiveninparenthesesareforinformationonly.2.ReferencedDocuments2.1ASTMStandards:2A90/A90MTestMethodforWeight[Mass]ofCoatingonIronandSteelArticleswithZincorZinc-AlloyCoatingsA700GuideforPackaging,Marking,andLoadingMethodsforSteelProductsforShipmentB6SpecificationforZincE8TestMethodsforTensionTestingofMetallicMaterialsE29PracticeforUsingSignificantDigitsinTestDatatoDetermineConformancewithSpecificationsF1043SpecificationforStrengthandProtectiveCoatingsonSteelIndustrialFenceFramework2.2ANSIStandard:B36.10WeldedandSeamlessWroughtSteelPipe33.OrderingInformation3.1Ordersformaterialunderthisspecificationshallincludethefollowingasrequired,todescribethedesiredmaterialadequately:3.1.1Specificationdesignation,3.1.2Quantity(feet,metres,ornumberoflengths),3.1.3Nameofmaterial(schedule40steelpipeorsched...