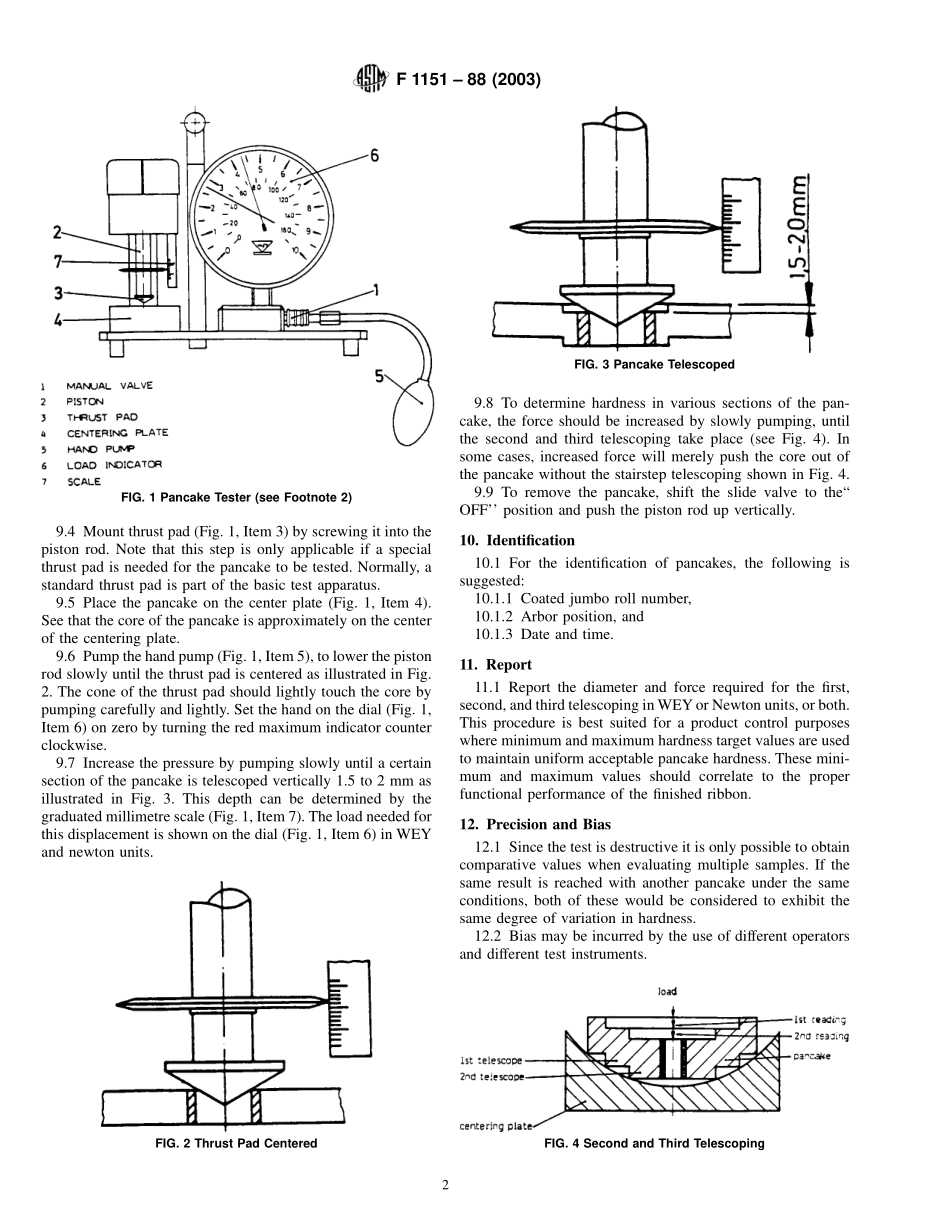

Designation:F1151–88(Reapproved2003)StandardTestMethodforDeterminingVariationsinHardnessofFilmRibbonPancakes1ThisstandardisissuedunderthefixeddesignationF1151;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(e)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethodcoversthedeterminationofvariationsinhardnessoffilmribbonpancakes.1.2Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.Definitions2.1pancake—asectionofribbonusuallywoundonacoreinsuchamannertoallowittobeinsertedinanindividualribboncartridge.2.2hardness—theabilityofthepancaketoresistverticaldeflectionwhenaloadisappliedaxiallytoitscore.2.3core—usuallyacylindricalplastictubeonwhicharibboniswound.2.4slitter—apieceofmachinerydesignedtoslitthewidthoflargeink-coatedfilmrollsandwindthenarrowfilmintoindividualpancakes.3.SummaryofTestMethod3.1Onrewindinganinkedribbon,eachlayerofinkedfilmshouldberewoundwithanequalforceresultinginauniformhardnessofapancake.However,thehardnessnearertothecoreisusuallyhigherthannearertotheperiphery.3.2Todeterminethevariationsinhardness,apancakeisputunderaknownverticalloaduntilapartofitistelescoped.Theloadingiscontinuedasotherportionsofthepancaketelescope.Theloadandposition,thatis,diameteroftelescoping,ateachloadlevelisnoted.Loadtestingcontinuesuntilthethirdtelescopingisobserved.3.3Alltestsmustbeperformedinduplicateunderthesameconditionsinordertocompareresults.4.SignificanceandUse4.1Thistestmethodenablesacomparisonofvariationinhardnessbetweenpancakesandallowsslitteroperatorstoadjustandmaintainthedesiredrewindingforce.5.Interferences5.1Widevariationsinenvironmentalconditions(tempera-ture,relativehumidity)couldaffectthepancake...