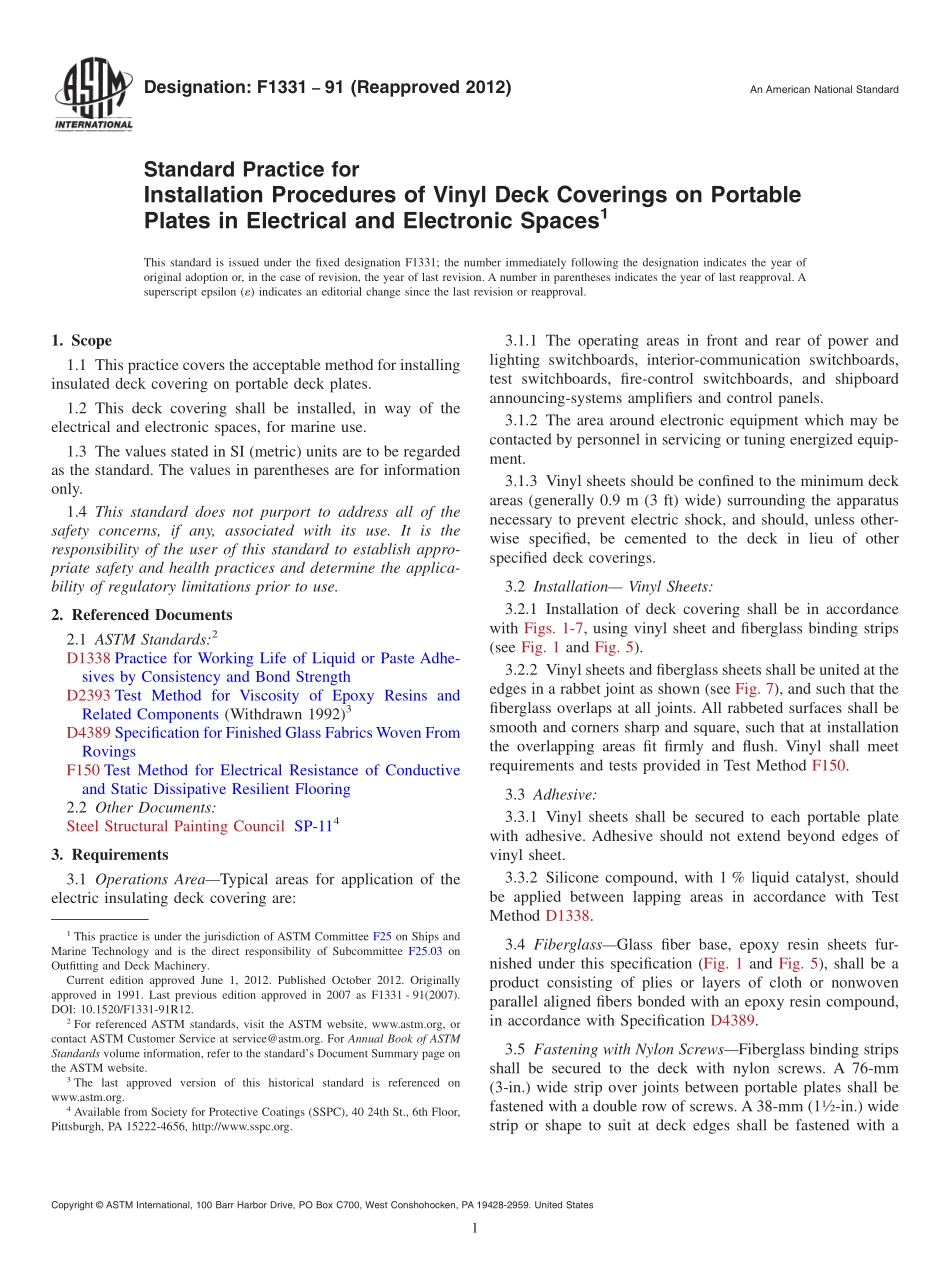

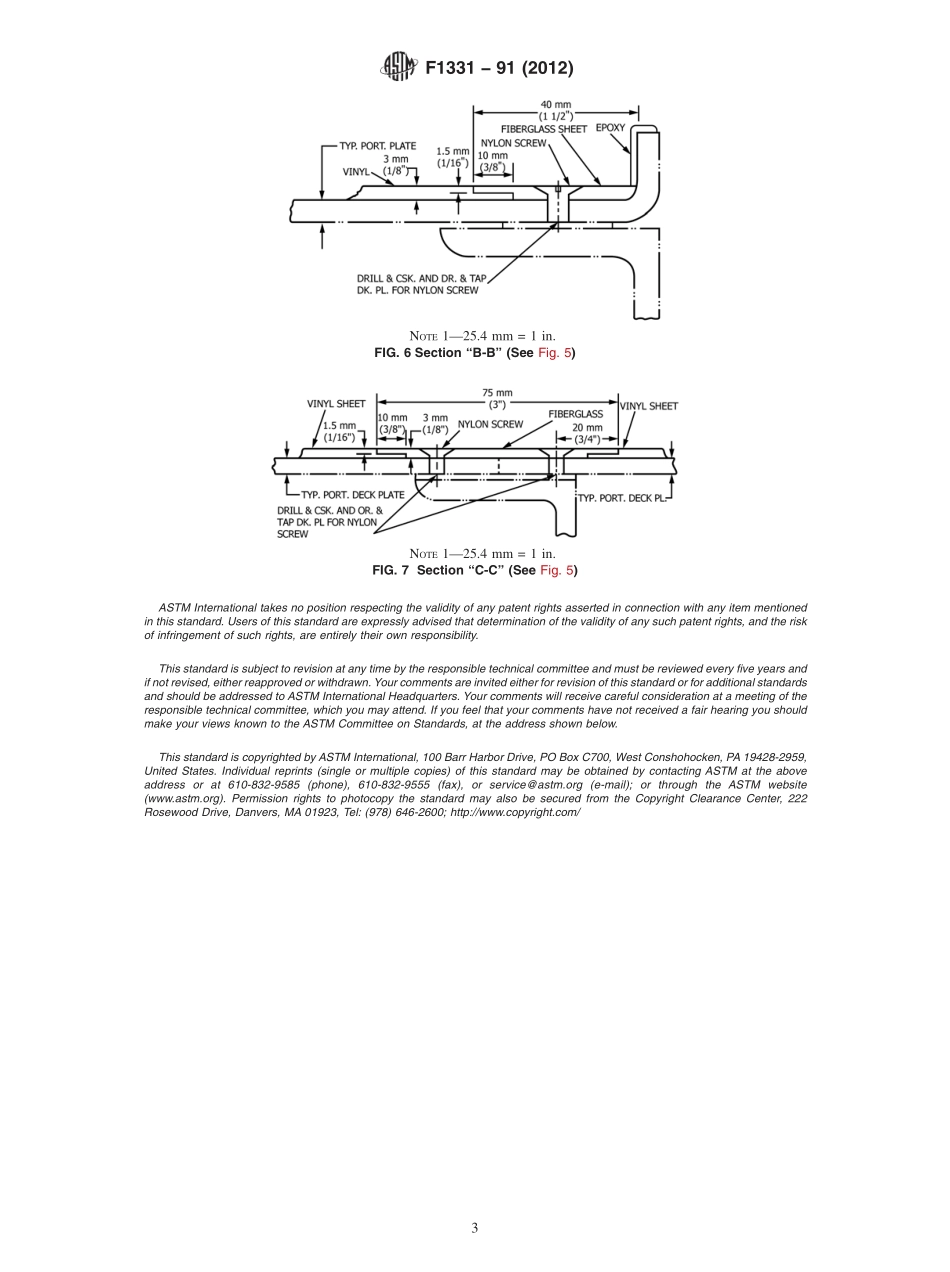

Designation:F1331−91(Reapproved2012)AnAmericanNationalStandardStandardPracticeforInstallationProceduresofVinylDeckCoveringsonPortablePlatesinElectricalandElectronicSpaces1ThisstandardisissuedunderthefixeddesignationF1331;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thispracticecoverstheacceptablemethodforinstallinginsulateddeckcoveringonportabledeckplates.1.2Thisdeckcoveringshallbeinstalled,inwayoftheelectricalandelectronicspaces,formarineuse.1.3ThevaluesstatedinSI(metric)unitsaretoberegardedasthestandard.Thevaluesinparenthesesareforinformationonly.1.4Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2D1338PracticeforWorkingLifeofLiquidorPasteAdhe-sivesbyConsistencyandBondStrengthD2393TestMethodforViscosityofEpoxyResinsandRelatedComponents(Withdrawn1992)3D4389SpecificationforFinishedGlassFabricsWovenFromRovingsF150TestMethodforElectricalResistanceofConductiveandStaticDissipativeResilientFlooring2.2OtherDocuments:SteelStructuralPaintingCouncilSP-1143.Requirements3.1OperationsArea—Typicalareasforapplicationoftheelectricinsulatingdeckcoveringare:3.1.1Theoperatingareasinfrontandrearofpowerandlightingswitchboards,interior-communicationswitchboards,testswitchboards,fire-controlswitchboards,andshipboardannouncing-systemsamplifiersandcontrolpanels.3.1.2Theareaaroundelectronicequipmentwhichmaybecontactedbypersonnelinservicingortuningenergizedequip-ment.3.1.3Vinylsheetsshouldbeconfinedtotheminimumdeckareas(generally0.9m(3ft)wide)surroundingtheapparatusnecessarytopreventelectricshock,andshould,unlessother-wisespecified,becementedto...