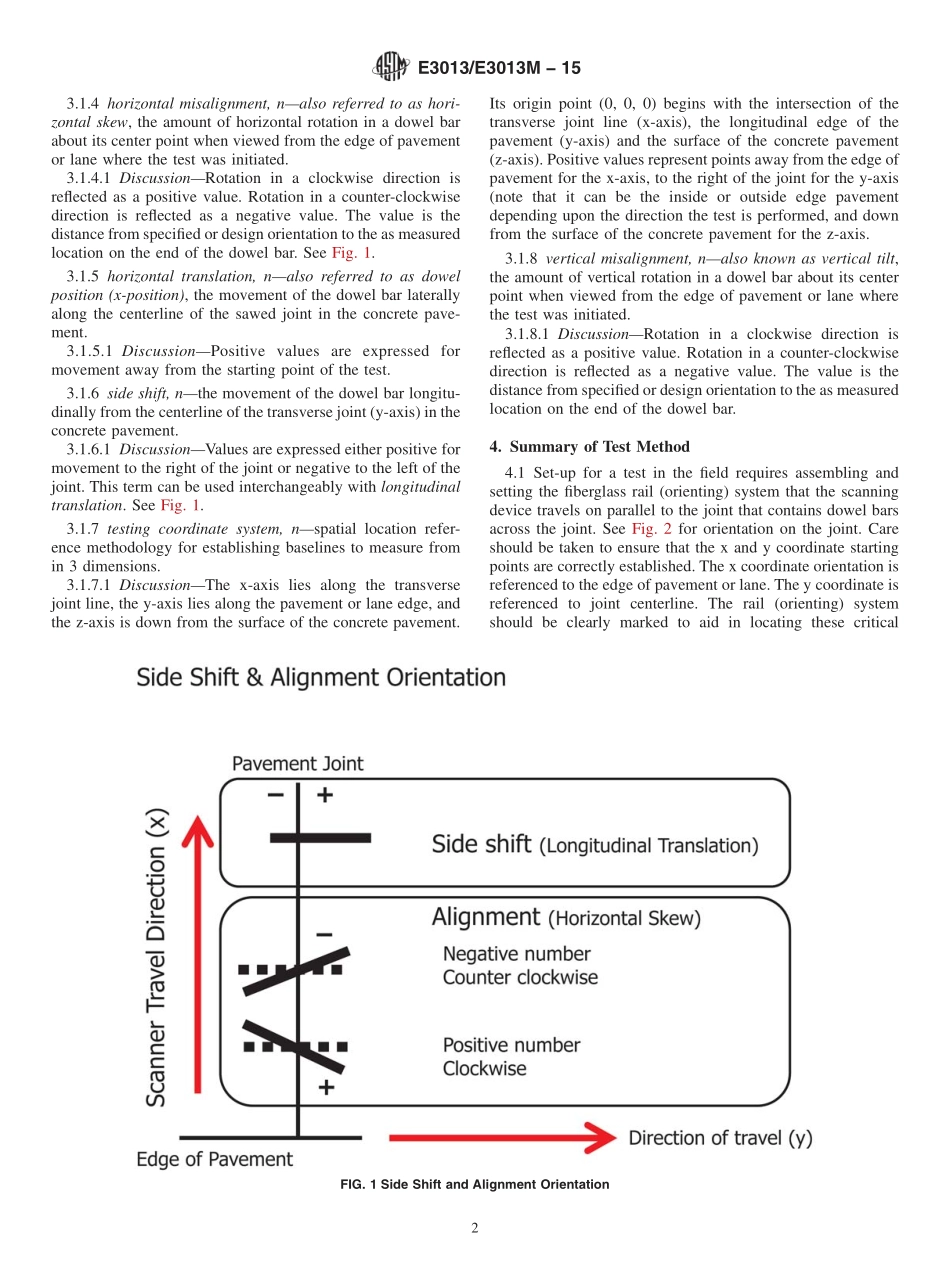

Designation:E3013/E3013M−15StandardTestMethodforEvaluatingConcretePavementDowelBarAlignmentUsingMagneticPulseInduction1ThisstandardisissuedunderthefixeddesignationE3013/E3013M;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethodcoverstheequipment,fieldprocedures,andinterpretationmethodsfortheassessmentofPortlandCementConcretePavementdowelbaralignmentusingMag-neticPulseInduction(MPI),alsoreferredtoasmagneticimagingtomographyoreddycurrenttomography.MagneticPulseInduction(MPI)devicesinduceaweakpulsedmagneticfieldthatcausestheinductionofeddycurrentsinmetalobjectsdisturbingthefield.Whenmetal(dowelbar)entersintothefieldanelectricalsignalisproducedandprocessedthroughalgorithmstodetectandproducequantitativevaluesforthedepth,alignmentandsideshiftlocationsofeachdowelandtiebarpresentinthepavementjoint.1.2MPIequipmentincludesthefollowingsystemsscanningdevicethatinducesthemagneticfieldandcollectstheelectricalsignal,orientationsystemsuchasarailsystem,fielddatacollectiondevicethatcollectsthesignaldatafromthescanner,performsfieldanalysis,andstoresdata,analysissoftwarepackagethatcalculatesthedowelbarpositions,allowsdataadjustmentstoaccountfordetectedanomaliesandproducesreports.1.3MPIfieldproceduresdescribethestepsandprocessesrequiredtocollectreliable,repeatableandaccurateresultsfromthescanneroperationandorientationsystem.Criticaltotheaccuracyistheabsenceofanymetalitemsexceptforthedowelbarsinthevicinityofthejointsbeingtested.Metalinthescannerandorientationsystemshouldbeminimized.Thescanneroperationprocedurescoverthecollectingofthedata,reviewingtheresultsonthefielddatacollector,anddetermin-ingifthedatacollectiontestwassuccessful.1.4MPIinterpretationmethodsdescribehowtoanalyzedatacollectedinthefieldprocedure,stepstakentoaddressinterferences,andanomaliesdisc...