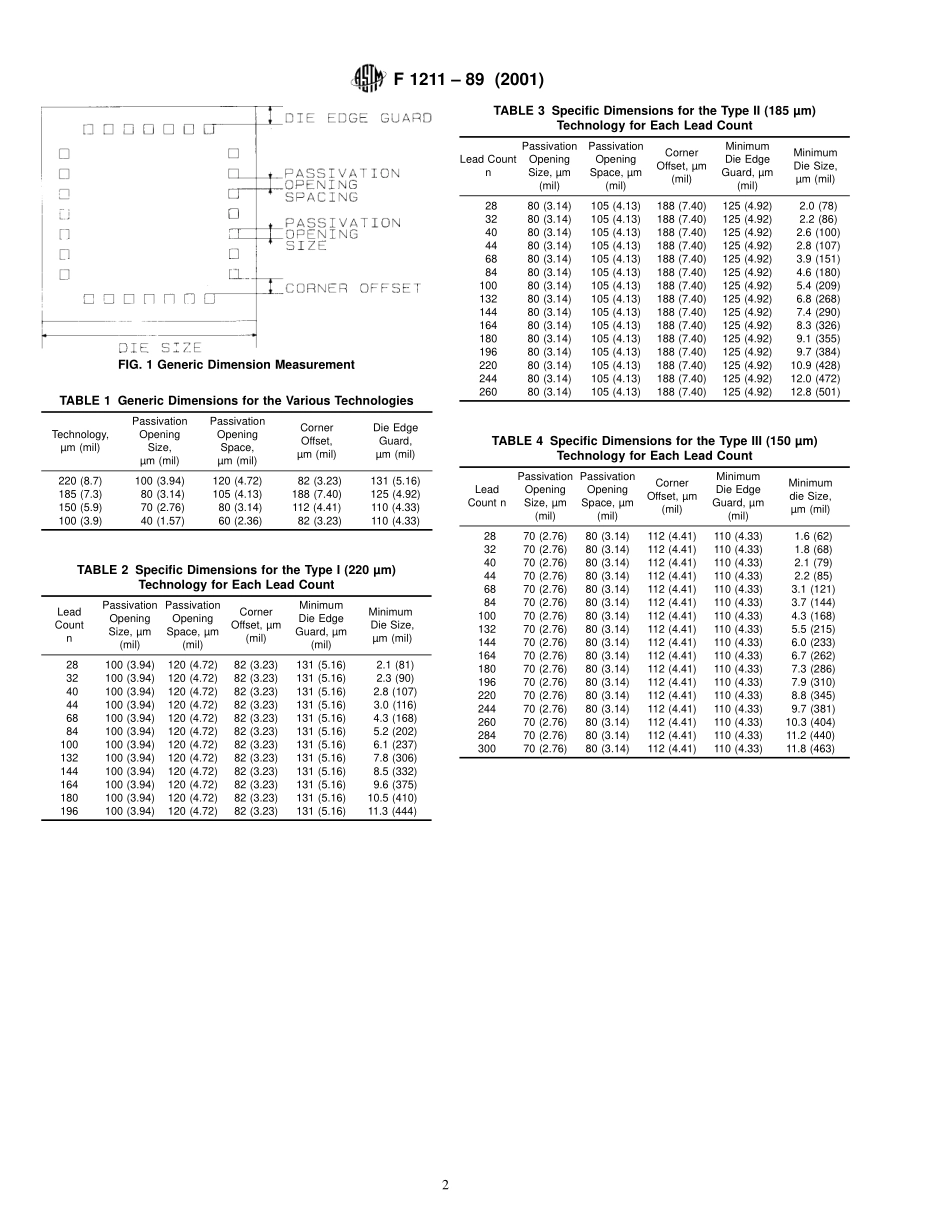

Designation:F1211–89(Reapproved2001)StandardSpecificationforSemiconductorDevicePassivationOpeningLayouts1ThisstandardisissuedunderthefixeddesignationF1211;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(e)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thisspecificationcoversstandardsemiconductordevicepassivationopeninglayoutsforvarioustapeautomatedbond-inginterconnectiontechnologies.1.2Thisspecificationestablishedthenominalpassivationopeningdimensions,nominalpassivation,openingspacing,nominalcornerpassivationopeningoffset,minimumscribeguardandminimumdiesizeforthemostcommoninput/outputcountswithineachtechnology.1.3Thisspecificationisextendabletootherinterconnectiontechnologiesifthepassivationopeningandspacingaread-justedinsuchawaythattheprogressionisnotmodified.1.4ThevaluesstatedinSIunitsaretoberegardedasthestandard.Thevaluesgiveninparenthesesareforinformationonly.2.Terminology2.1Definitions:2.1.1corneroffset—Theorthogonaldistancebetweenthecornerpassivationopeningonadjacentsidesofthediewhereacornerpassivationopeningisindentifiedastheendpassiva-tionopeningonadieside.2.1.2leadcount—Thenumberofpassivationopeningsavailableonafullypopulateddielayout.2.1.3minimumdieedgeguard—Theminimumdistancebetweenthedieedgeandthepassivationopeningnearesttothedieedgehereinusedtoestablishtheminimumdiesize.2.1.4minimumdiesize—Theminimumdiesizeiscalcu-latedbythefollowingequation:minimumdiesize5~~leadcount/4!~p.o.size1p.o.space!!2p.o.space1~2~corneroffset1p.o.size1dieedgeguard!!2.1.5passivationopening—Theunpassivatedareawithinthedevicemetalbondingpadarea.2.1.6passivationopeningsize—Theminimumothagonaldimensionsofthepassivationopeningfortheparticulartechnologyhereinusedasthenominalpassivationopeningsize.2.1.7passivationopeningspace—Theminimumspacebe-tweenadjacentpassivationopeningsfortheparticulartechnol-ogyhereinus...