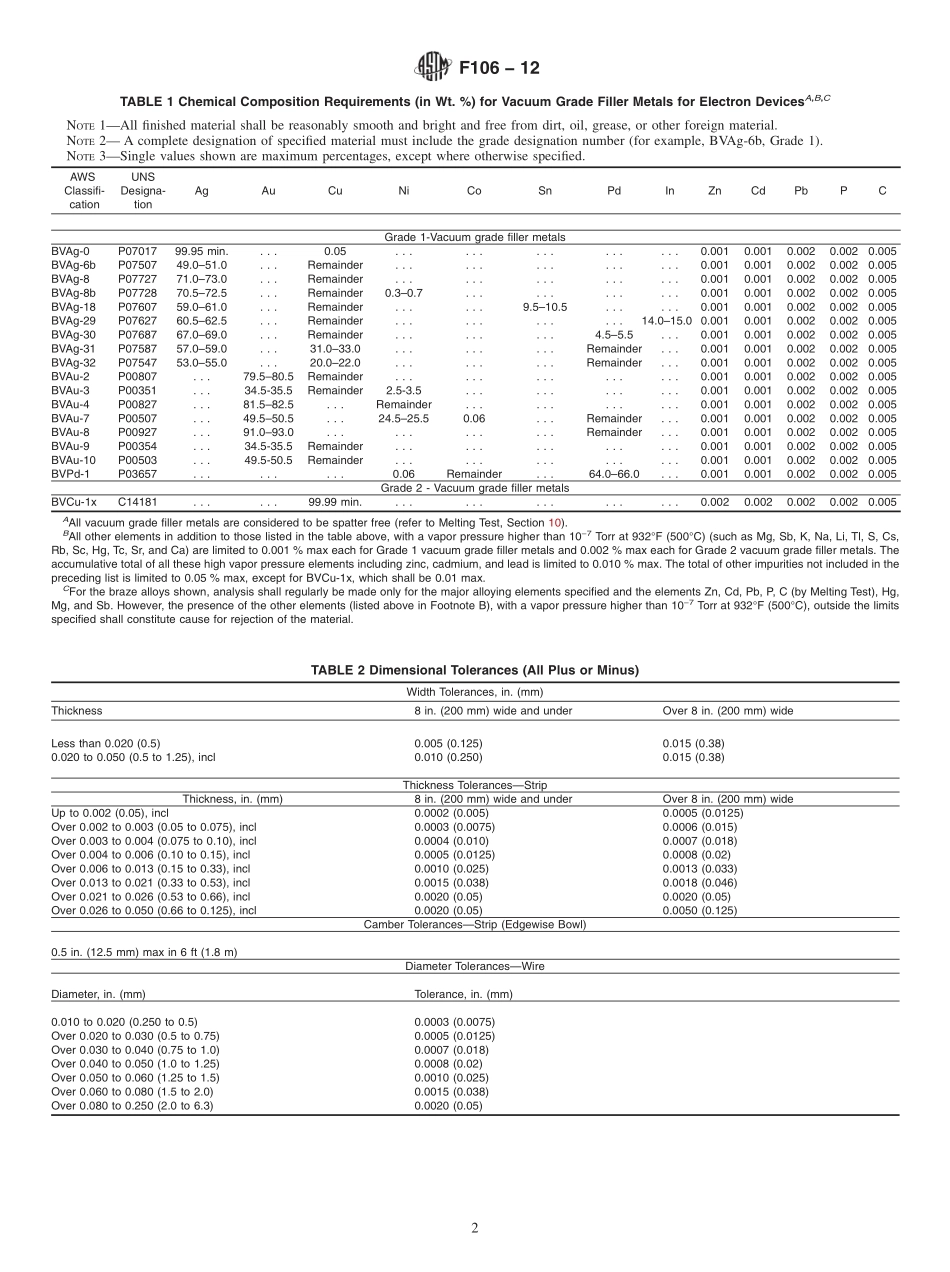

Designation:F106−12StandardSpecificationforBrazingFillerMetalsforElectronDevices1ThisstandardisissuedunderthefixeddesignationF106;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thisspecificationcoversrequirementsorfillermetalssuitableforbrazinginternalpartsandothercriticalareasofelectrondevicesinanonoxidizingatmosphere(Note1).1.2Thesematerialsareavailableinstriporwireorpreformsmadebyblankingthestriporbendingthewire.Powdersarealsoavailable.NOTE1—BrazingfillermetalsforgeneralapplicationsarespecifiedinAWSSpecificationA5.8.1.3Thevaluesstatedininch-poundunitsaretoberegardedasstandard.ThevaluesgiveninparenthesesaremathematicalconversionstoSIunitsthatareprovidedforinformationonlyandarenotconsideredstandard.2.ReferencedDocuments2.1ASTMStandards:2B214TestMethodforSieveAnalysisofMetalPowdersE11SpecificationforWovenWireTestSieveClothandTestSievesF19TestMethodforTensionandVacuumTestingMetal-lizedCeramicSeals2.2AmericanWeldingSociety:3A5.8SpecificationforBrazingFillerMetalsC3.2MethodforEvaluatingtheStrengthofBrazedJointsC3.3RecommendedPracticesforDesign,ManufactureandInspectionofCriticalBrazedComponents3.Classification3.1BrazingfillermetalswhicharevacuumgradeandareclassifiedonthebasisofchemicalcompositionshowninTable1.ThedifferencebetweenGrade1and2istheallowableimpuritycontent.Grade1requiresgenerallylowerlevelsofimpurities.4.OrderingInformation4.1Ordersformaterialtothisspecificationshallincludethefollowinginformation:4.1.1Quantity,4.1.2Dimensionsandtolerances(Table2),4.1.3Form(rod,bar,wire,etc.),4.1.4AWSclassification(Table1),4.1.5Grade1,4.1.6Specialrequirementsorexceptions,and4.1.7Certification—Stateifcertificationisrequired.5.MaterialsandManufacture5.1Thebrazingfillermetalsshallbevacuumgradeandfabricatedbyanymethodthatyieldsaproductconformingtotherequirem...