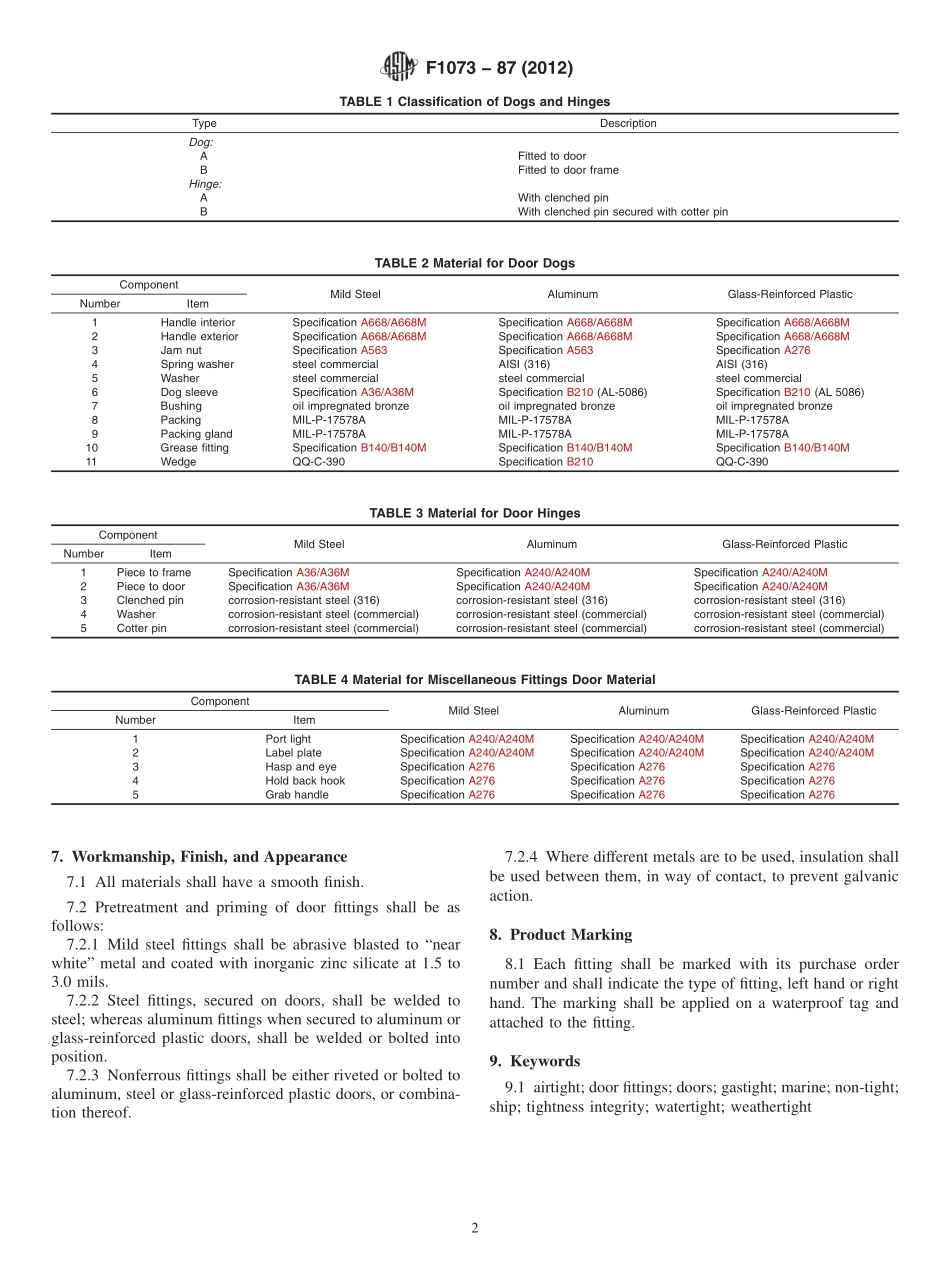

Designation:F1073−87(Reapproved2012)AnAmericanNationalStandardStandardSpecificationforDoorFittings,forWatertight/Gastight/Airtight,Weathertight,andNon-TightDoors,forMarineUse1ThisstandardisissuedunderthefixeddesignationF1073;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thisspecificationcoverstheprincipaldesignandtypeofmaterialformanufacturingfittingsforwatertight/gastight/airtight,weathertight,andnon-tightdoors,formarineuse.Notethat“gastight”iscommercialterminologywhichalsomeans“airtight”innavalterminology.1.2Thefittingsareintendedforuseonalldoorsformarineuse,exceptjoinerandexpandedmetaldoors.2.ReferencedDocuments2.1ASTMStandards:2A36/A36MSpecificationforCarbonStructuralSteelA240/A240MSpecificationforChromiumandChromium-NickelStainlessSteelPlate,Sheet,andStripforPressureVesselsandforGeneralApplicationsA276SpecificationforStainlessSteelBarsandShapesA563SpecificationforCarbonandAlloySteelNutsA668/A668MSpecificationforSteelForgings,CarbonandAlloy,forGeneralIndustrialUseB140/B140MSpecificationforCopper-Zinc-Lead(RedBrassorHardwareBronze)Rod,Bar,andShapesB210SpecificationforAluminumandAluminum-AlloyDrawnSeamlessTubes2.2MilitaryStandards:3MIL-P-24441Epoxy-PolyamidePaintMIL-P-17578APackingMaterial,Plastic(forDogsforWa-tertightClosures)(Symbol1425)MIL-C-81706Coating,AluminumandAluminumAlloysDOD-STD-2138MetalSprayedCoatingSystemsforCorro-sionProtection2.3FederalSpecifications:3QQ-C-390CopperAlloyCastingsTT-E-490Enamel-SiliconeAlkydCopolymer,Semi-gloss,Exterior2.4ANSIStandard:A2.6StandardforFireTestsofWindowAssemblies42.5AISIStandard:316LowAlloyStainlessSteel(Cres316)53.Classification3.1ThedogsandhingesshallbeclassifiedasgiveninTable1.4.OrderingInformation4.1Orderingforfittingsshallbeindicatedonthepurchaseorderpreparedfordoors,withreferencetothisspec...