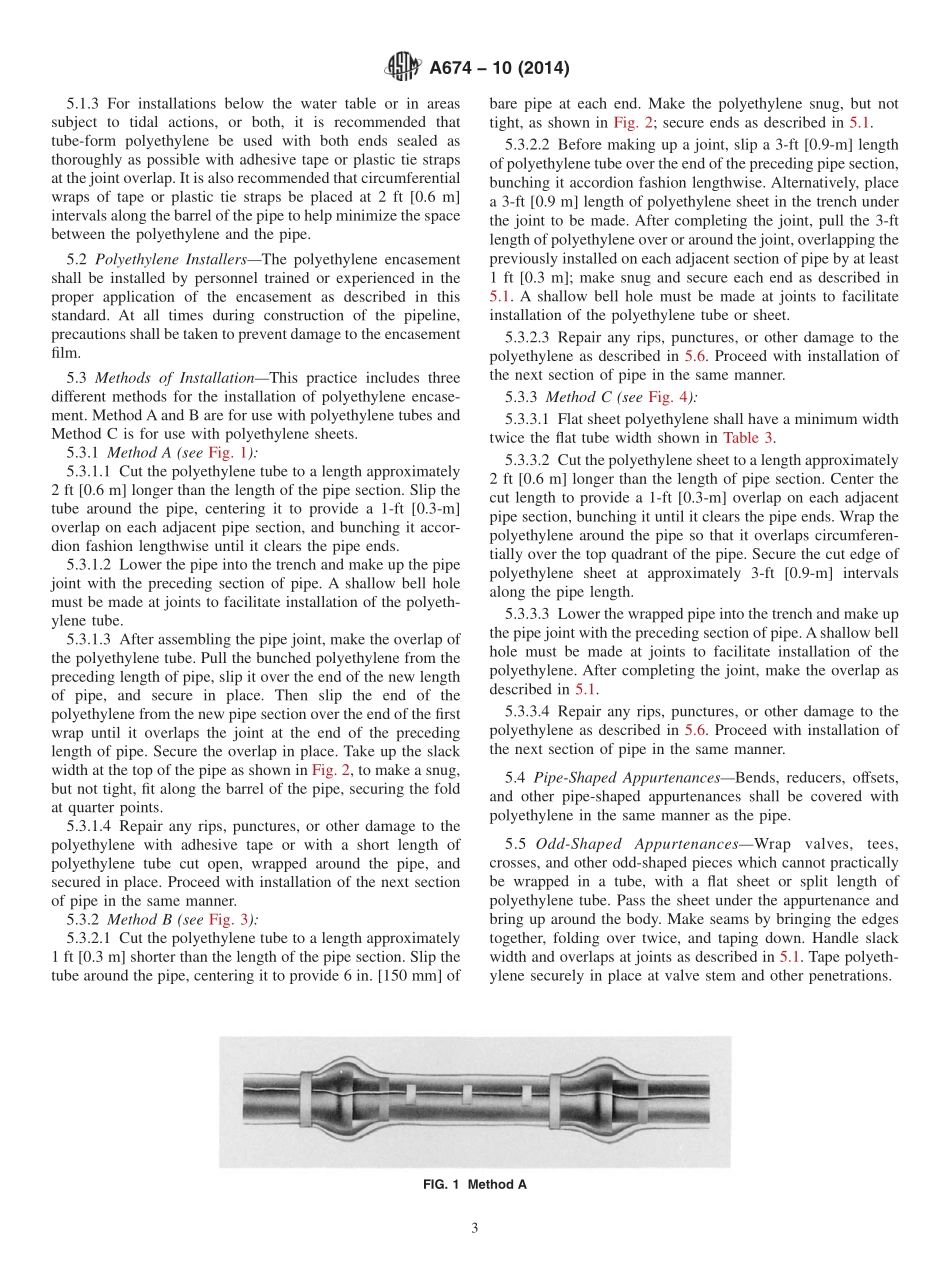

Designation:A674−10(Reapproved2014)StandardPracticeforPolyethyleneEncasementforDuctileIronPipeforWaterorOtherLiquids1ThisstandardisissuedunderthefixeddesignationA674;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thispracticecoversmaterialsandinstallationproce-duresforpolyethyleneencasementtobeappliedtounder-groundinstallationsofductileironpipe.Itmayalsobeusedforpolyethyleneencasementoffittings,valves,andotherappur-tenancestoductileironpipesystems.1.2Thevaluesstatedininch-poundunitsaretoberegardedasstandard.ThevaluesgiveninparenthesesaremathematicalconversionstoSIunitsthatareprovidedforinformationonlyandarenotconsideredstandard.1.2.1ImportantSIvaluesareprovidedinbrackets.Also,certainimportantSIvaluesappearwithoutbracketsorparen-theses.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2D149TestMethodforDielectricBreakdownVoltageandDielectricStrengthofSolidElectricalInsulatingMaterialsatCommercialPowerFrequenciesD882TestMethodforTensilePropertiesofThinPlasticSheetingD1709TestMethodsforImpactResistanceofPlasticFilmbytheFree-FallingDartMethodD1922TestMethodforPropagationTearResistanceofPlasticFilmandThinSheetingbyPendulumMethodD4976SpecificationforPolyethylenePlasticsMoldingandExtrusionMaterials2.2ANSI/AWWAStandards:3C600InstallationofDuctileIronWaterMainsandTheirAppurtenancesC105⁄A21.5PolyethyleneEncasementforDuctile-IronPipeSystems3.Terminology3.1Definitions:3.1.1high-density,cross-laminatedpolyethylenefilm—Filmextrudedfromvirginhigh-densitypolyethylenerawmaterial,whichisthenmolecularlyorientedbystretching.Thefinalproduc...