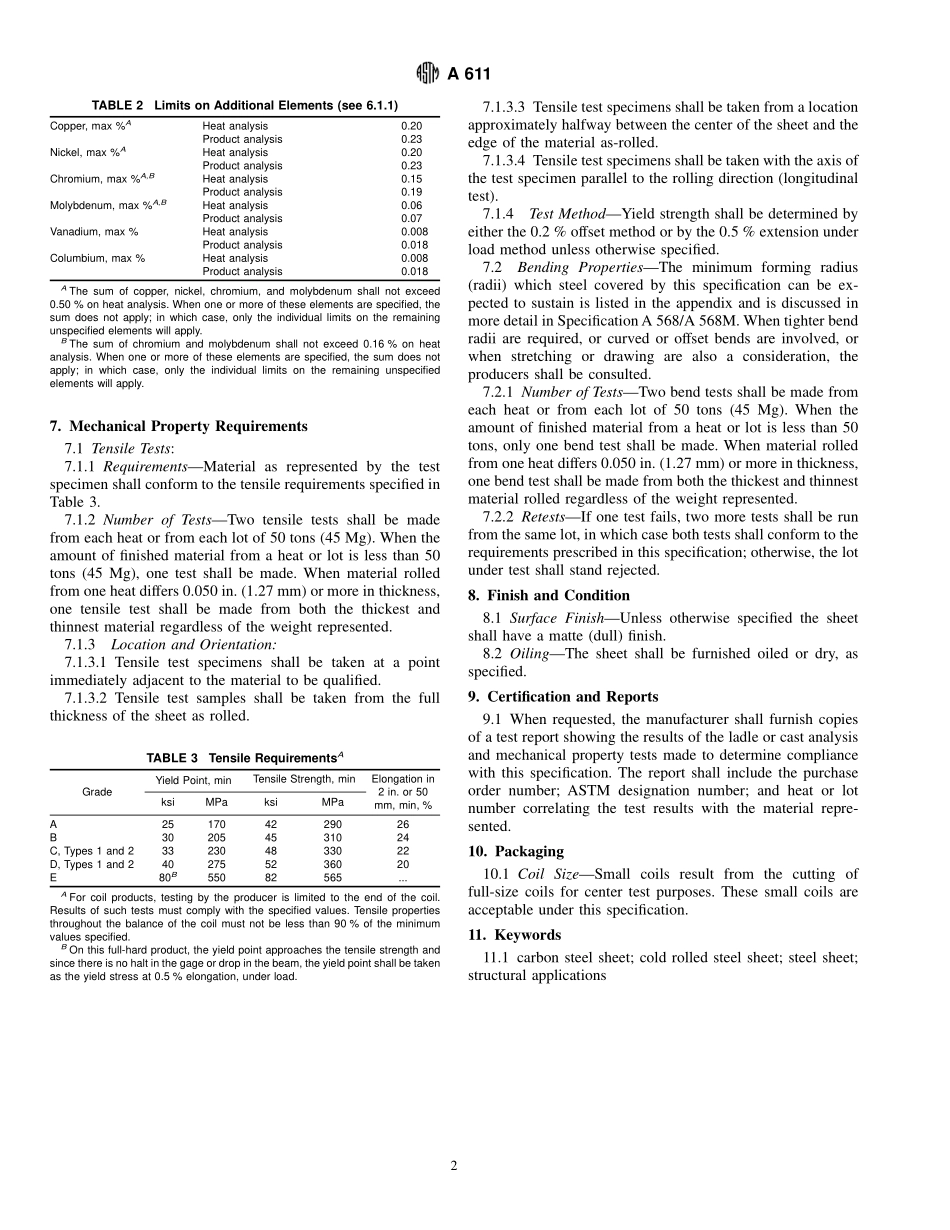

Designation:A611–97StandardSpecificationforStructuralSteel(SS),Sheet,Carbon,Cold-Rolled1ThisstandardisissuedunderthefixeddesignationA611;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(e)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheDepartmentofDefense.1.Scope1.1Thisspecificationcoverscold-rolledcarbonstructuralsteel(SS)sheet,incutlengthsorcoils.ItincludesfivestrengthlevelsdesignatedasGradeAwithyieldpoint25ksi(170MPa)minimum;GradeBwith30ksi(205MPa)minimum;GradeCTypes1and2with33ksi(230MPa)minimum;GradeDTypes1and2with40ksi(275MPa)minimum;andGradeEwith80ksi(550MPa)minimum.1.2GradesA,B,C,andDhavemoderateductilitywhereasGradeEisafull-hardproductwithnospecifiedminimumelongation.1.3Thevaluesstatedininch-poundunitsaretoberegardedasthestandard.2.ReferencedDocuments2.1ASTMStandards:A568/A568MSpecificationforSteel,Sheet,Carbon,andHigh-Strength,Low-Alloy,Hot-RolledandCold-Rolled,GeneralRequirementsfor23.Terminology3.1Definition:3.1.1structuralsteel(SS)sheet—sheetproducedtotensilepropertyvaluesasspecifiedorrequired.4.OrderingInformation4.1Ordersformaterialunderthisspecificationshallincludethefollowinginformation,asrequired,todescribethematerialadequately.4.1.1ASTMspecificationnumber,dateofissue,andgrade(ifGradesCorD,indicateType1orType2),4.1.2Copper-bearingsteel(ifrequired),4.1.3Specialrequirements(ifrequired),4.1.4Nameofmaterial(cold-rolledsheet),structuralqual-ity,4.1.5Finish;matte(dull)finishwillbesuppliedunlessotherwiseordered,4.1.6Condition(oiledordry),and4.1.7Dimensions.4.1.7.1Asagreeduponbetweenthepurchaserandtheproducer,materialorderedtothisspecificationwillbesuppliedtomeettheappropriatestandardorrestrictedthicknesstoler-ancetableshowninSpecificationA568/A568M.NOTE1—NotallproducersarecapableofmeetingallofthelimitationsofthethicknesstolerancetablesinSpecificatio...