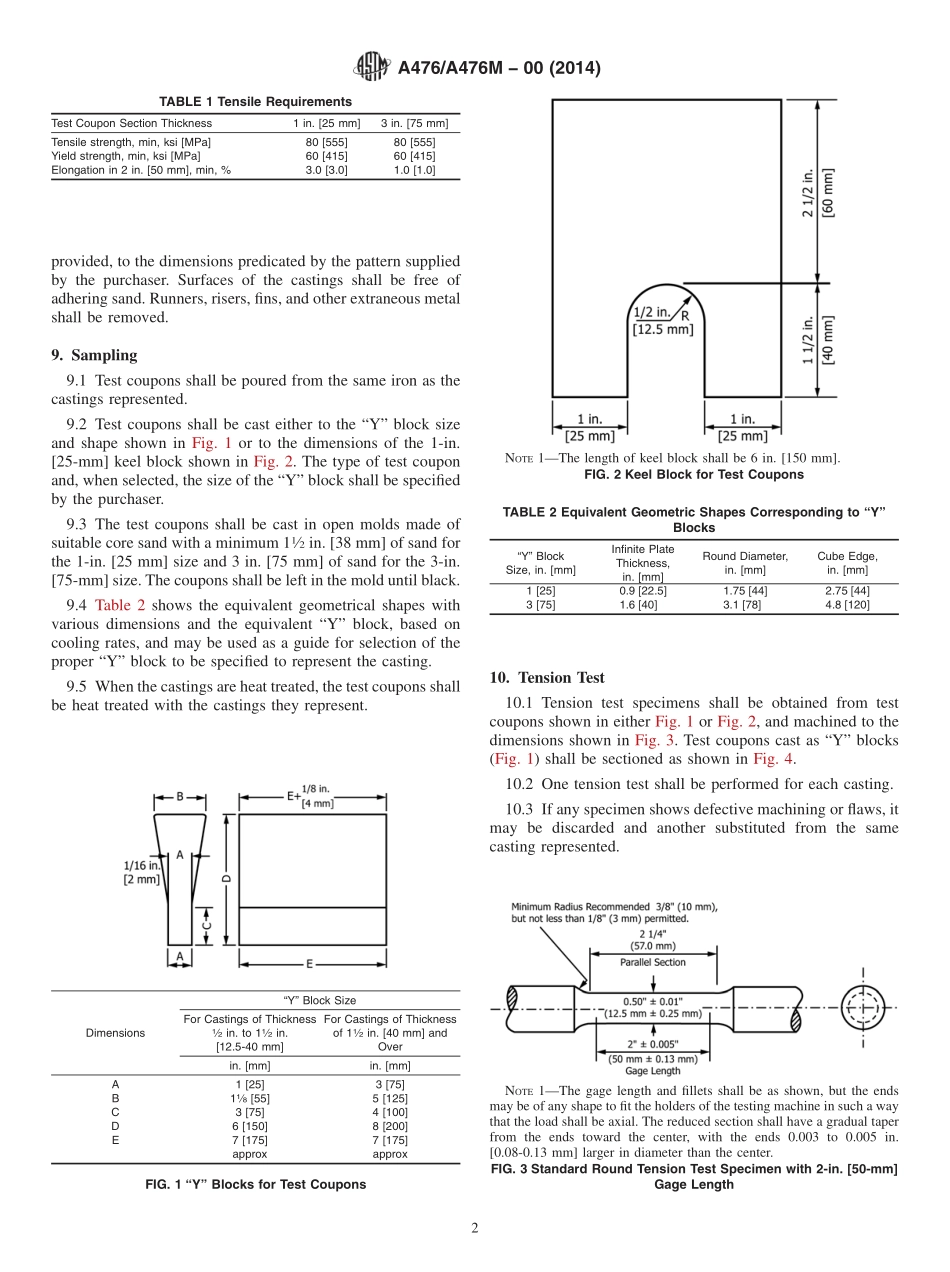

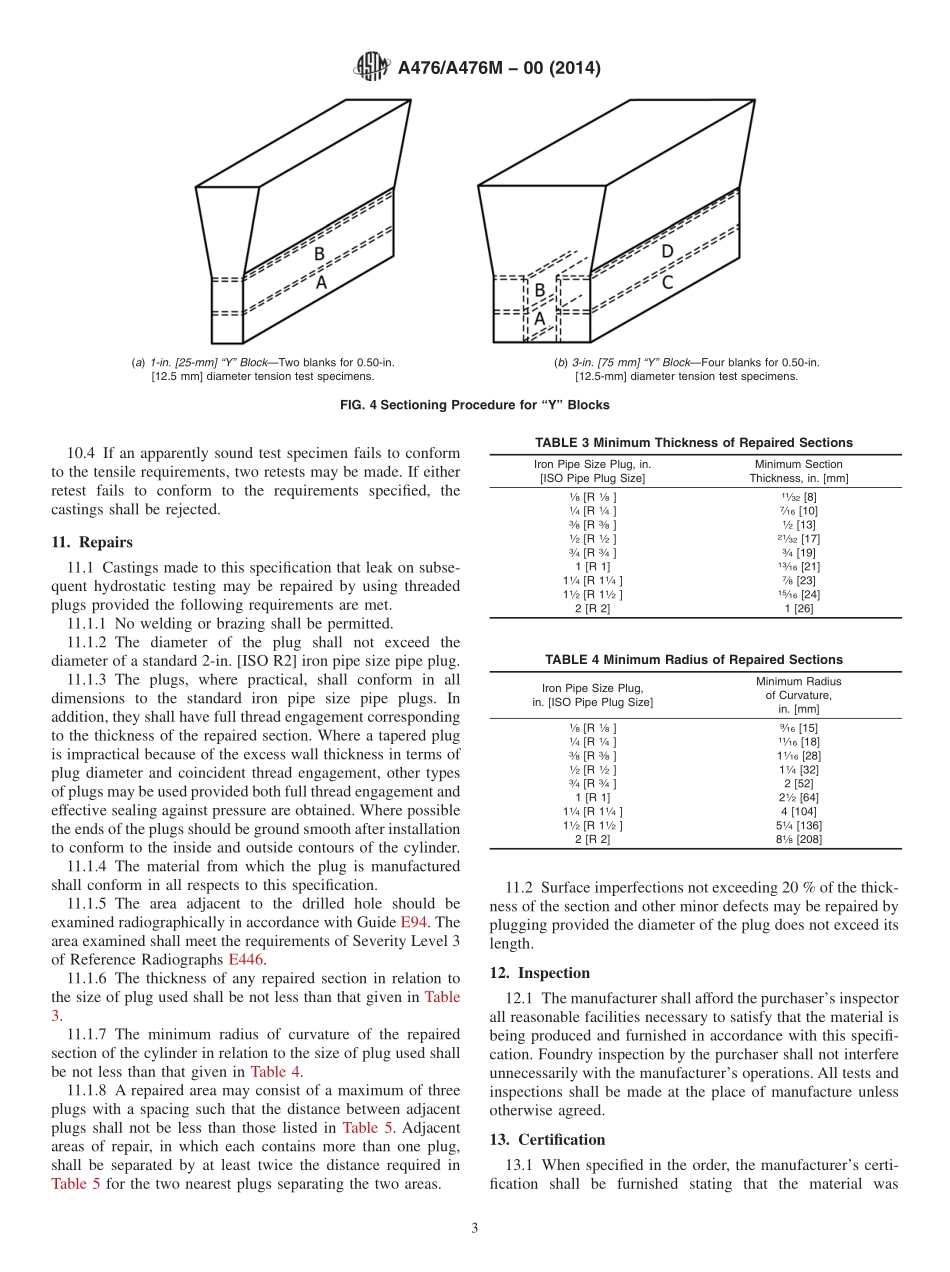

Designation:A476/A476M−00(Reapproved2014)StandardSpecificationforDuctileIronCastingsforPaperMillDryerRolls1,2ThisstandardisissuedunderthefixeddesignationA476/A476M;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thisspecificationcoversductileironcastingsforuseinpressurecontainingpapermilldryerrollsattemperaturesupto450°F[230°C].1.2Noprecisequantitativerelationshipcanbestatedbe-tweenthepropertiesoftheironinvariouslocationsofthesamecastingorbetweenthepropertiesofacastingandthoseofatestspecimencastfromthesameiron(seeAppendixX1).1.3ThevaluesstatedineitherSIunitsorinch-poundunitsaretoberegardedseparatelyasstandard.Thevaluesstatedineachsystemmaynotbeexactequivalents;therefore,eachsystemshallbeusedindependentlyoftheother.Combiningvaluesfromthetwosystemsmayresultinnon-conformancewiththestandard.1.3.1Exception—Withinthetext,theSIunitsareshowninbrackets.2.ReferencedDocuments2.1ASTMStandards:3A644TerminologyRelatingtoIronCastingsE8TestMethodsforTensionTestingofMetallicMaterialsE10TestMethodforBrinellHardnessofMetallicMaterialsE94GuideforRadiographicExaminationE446ReferenceRadiographsforSteelCastingsUpto2in.(50.8mm)inThickness3.Terminology3.1DefinitionsformanytermscommontoironcastingsarefoundinTerminologyA644.4.OrderingInformation4.1Ordersformaterialpurchasedtotherequirementsofthisspecificationshouldincludethefollowinginformation:4.1.1Quantity,4.1.2Specificationnumberanddateofissue,4.1.3Descriptionofcastingbypatternnumberordrawing,4.1.4Heattreatment,ifrequired(see5.1),4.1.5Typeoftestcoupon(see9.2),4.1.6Certification,ifrequired(see13.1),4.1.7Markinglocation(see14.1),and4.1.8Additionalrequirements.5.HeatTreatment5.1Thecastingsmaybestressrelievedatatemperaturenottoexceed1200°F[650°C].6.ChemicalRequirements6.1Thecastingsshallconformtothefollowingchemicalrequ...