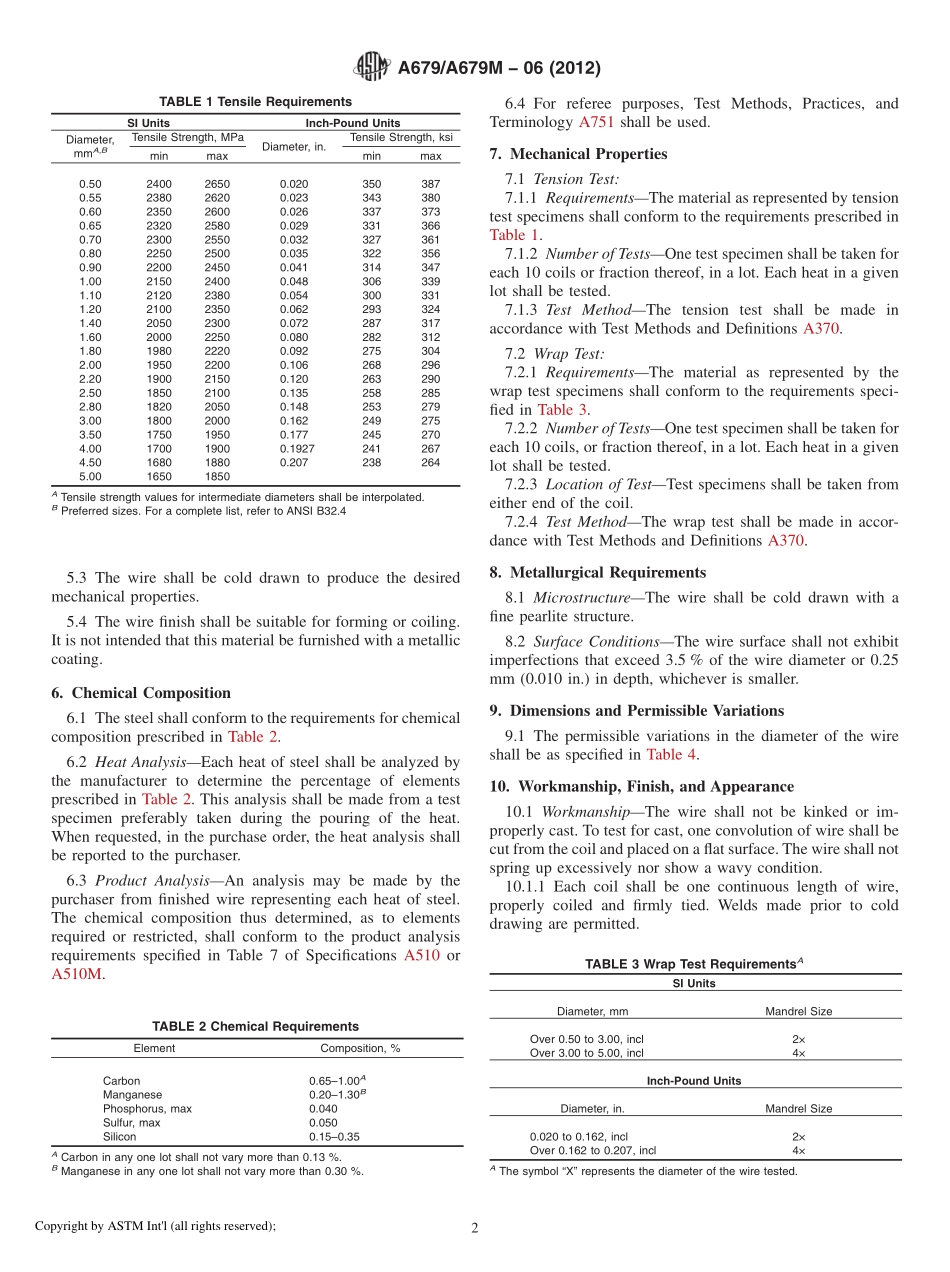

Designation:A679/A679M−06(Reapproved2012)StandardSpecificationforSteelWire,HighTensileStrength,ColdDrawn1ThisstandardisissuedunderthefixeddesignationA679/A679M;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope*1.1Thisspecificationcoversround,uncoated,hightensilestrength,cold-drawnsteelspringwire,havingpropertiesandqualitysuitableforthemanufactureofmechanicalspringsandwireformssubjecttohighstaticstressesorinfrequentdynamicload,orboth.1.2ThevaluesstatedineitherSIunitsorinch-poundunitsaretoberegardedseparatelyasstandard.Thevaluesstatedineachsystemarenotexactequivalents;therefore,eachsystemmustbeusedindependentlyoftheother.2.ReferencedDocuments2.1ASTMStandards:2A370TestMethodsandDefinitionsforMechanicalTestingofSteelProductsA510SpecificationforGeneralRequirementsforWireRodsandCoarseRoundWire,CarbonSteelA510MSpecificationforGeneralRequirementsforWireRodsandCoarseRoundWire,CarbonSteel(Metric)A700PracticesforPackaging,Marking,andLoadingMeth-odsforSteelProductsforShipmentA751TestMethods,Practices,andTerminologyforChemi-calAnalysisofSteelProductsA941TerminologyRelatingtoSteel,StainlessSteel,RelatedAlloys,andFerroalloysE29PracticeforUsingSignificantDigitsinTestDatatoDetermineConformancewithSpecifications2.2ANSIStandard:3B32.4PreferredMetricSizesforRound,Square,Rectangle,andHexagonMetalProducts2.3FederalStandard:4Fed.Std.No.123MarkingforShipment(CivilAgencies)2.4AIAGStandard:5AIAGB-502.00PrimaryMetalsIdentificationTagApplica-tionStandard3.Terminology3.1Definitions—Fordefinitionsoftermsusedinthisspeci-fication,refertoTerminologyA941.4.OrderingInformation4.1Itshallbetheresponsibilityofthepurchasertospecifyallrequirementsthatarenecessaryformaterialunderthisspecification.Suchrequirementsmayinclude,butarenotlimitedto,thefollowing:4.1.1Quantity(mass),4.1.2Nameofmater...