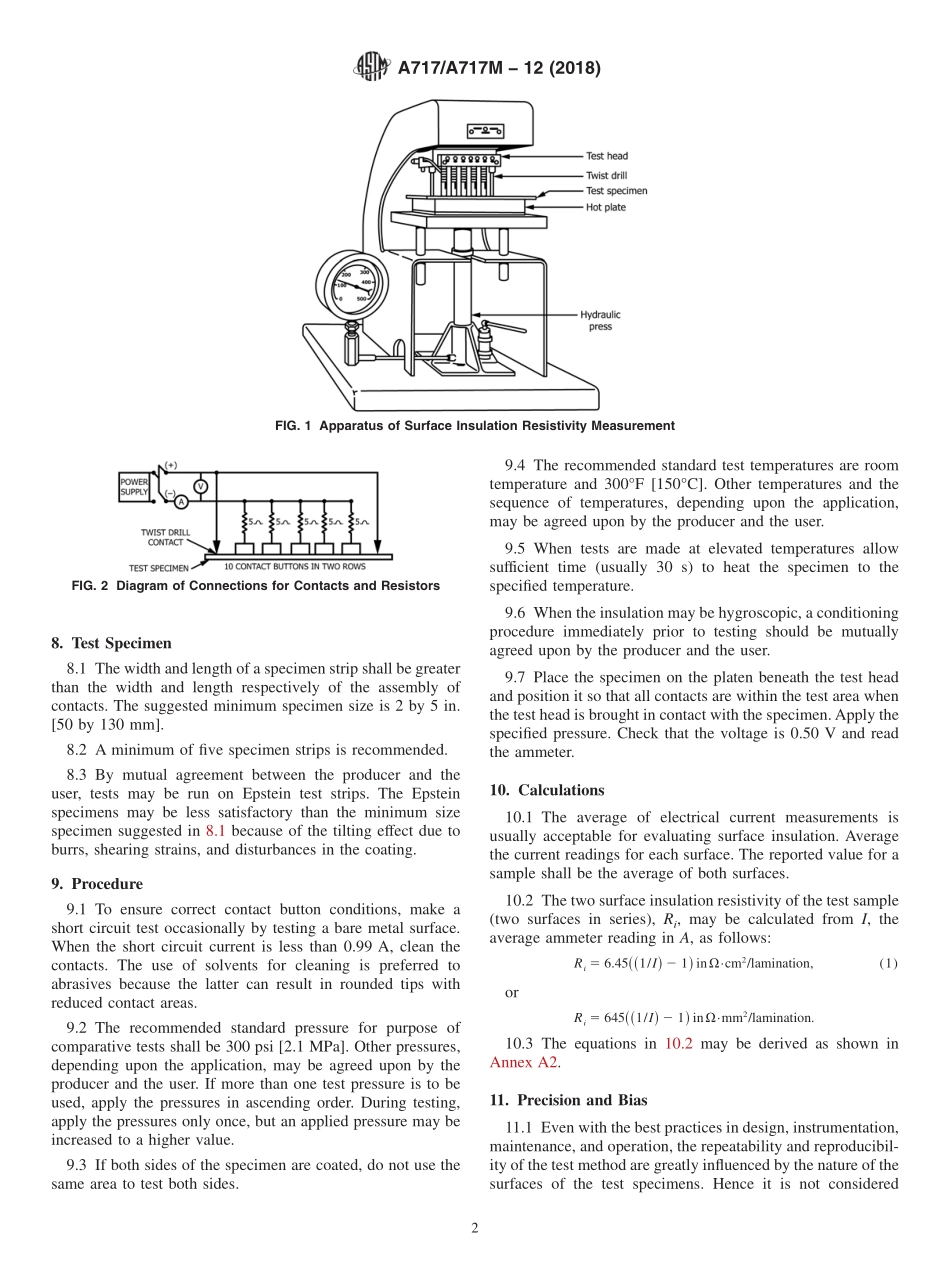

Designation:A717/A717M−12(Reapproved2018)StandardTestMethodforSurfaceInsulationResistivityofSingle-StripSpecimens1ThisstandardisissuedunderthefixeddesignationA717/A717M;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethodcoversameansoftestingthesurfaceinsulationresistivityofsinglestripsorpunchingsofflat-rolledelectricalsteelunderpredeterminedconditionsofvoltage,pressure,andtemperature.1.2ThevaluesstatedineitherSIunitsorinch-poundunitsaretoberegardedseparatelyasstandard.Thevaluesstatedineachsystemmaynotbeexactequivalents;therefore,eachsystemshallbeusedindependentlyoftheother.Combiningvaluesfromthetwosystemsmayresultinnon-conformancewiththestandard.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafety,health,andenvironmentalpracticesanddeter-minetheapplicabilityofregulatorylimitationspriortouse.1.4Thisinternationalstandardwasdevelopedinaccor-dancewithinternationallyrecognizedprinciplesonstandard-izationestablishedintheDecisiononPrinciplesfortheDevelopmentofInternationalStandards,GuidesandRecom-mendationsissuedbytheWorldTradeOrganizationTechnicalBarrierstoTrade(TBT)Committee.2.ReferencedDocuments2.1ASTMStandards:2A34/A34MPracticeforSamplingandProcurementTestingofMagneticMaterials3.Terminology3.1DefinitionsofTermsSpecifictoThisStandard:3.1.1surfaceinsulationresistivity—referstotheeffectiveresistivityofasingleinsulativelayertestedbetweenappliedbaremetalcontactsandthebasemetaloftheinsulatedtestspecimen.Itisnotthesameasthetermsinterlaminarresistivityandstackresistivity,whichrefertotheaverageresistivityoftwoadjacentinsulativesurfacesincontactwitheachother.3.1.2TheapparatusispopularlyknownasaFranklintester.4.SummaryofTestMethod4.1Tenmetall...