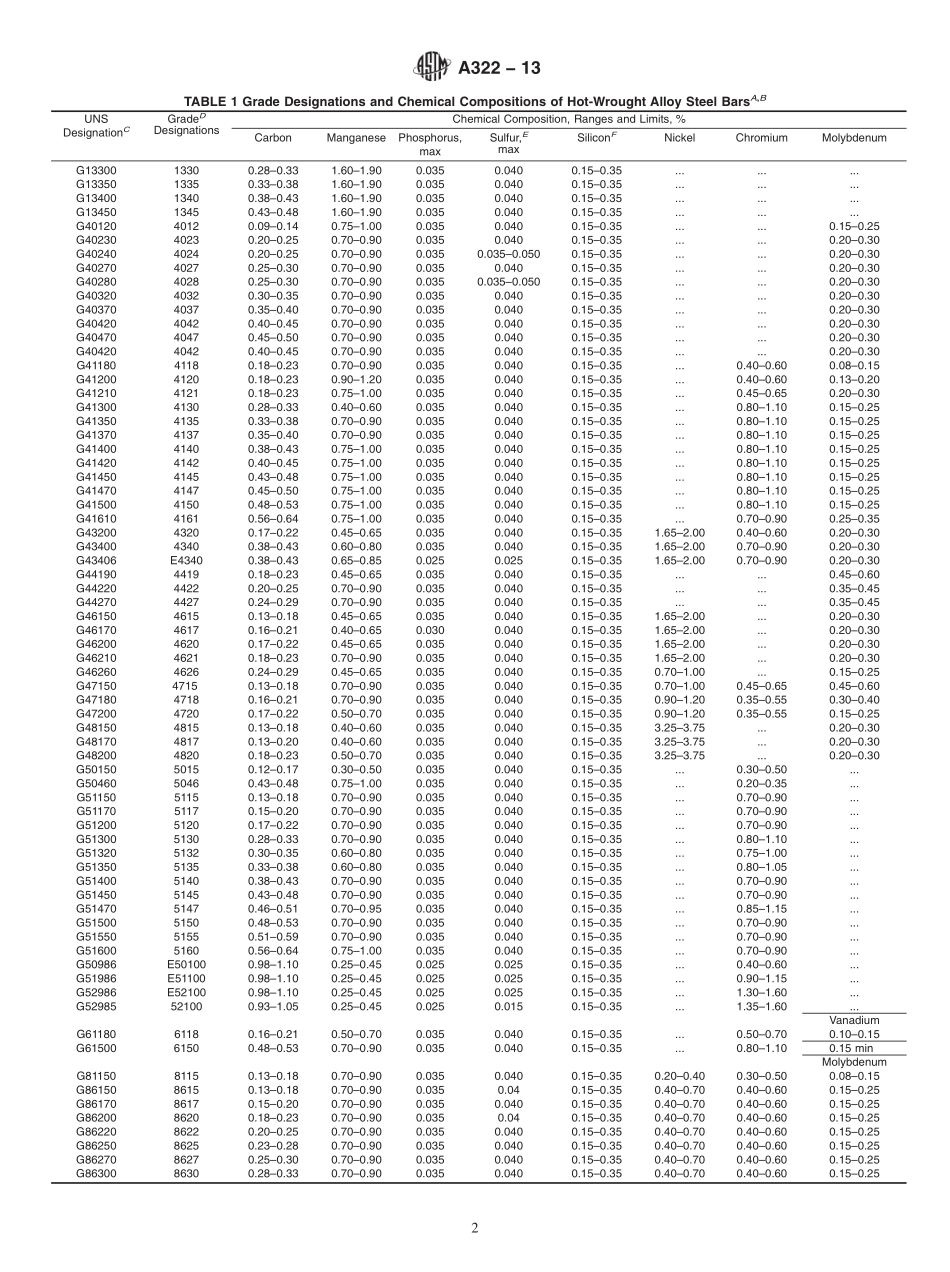

Designation:A322−13StandardSpecificationforSteelBars,Alloy,StandardGrades1ThisstandardisissuedunderthefixeddesignationA322;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheDepartmentofDefense.1.Scope1.1Thisspecificationcovershot-wroughtalloysteelbars.Barapplicationsincludeforging,heattreating,colddrawing,machiningandmanystructuralcomponents(Note1).NOTE1—AguidefortheselectionofsteelbarsiscontainedinPracticeA400.1.2ThebarsshallbefurnishedinthegradesspecifiedinTable1.SectionsandsizesofbarsteelavailablearecoveredinSpecificationA29/A29M.Hot-wroughtalloysteelbarsareproducedincutlengthsandcoils;themanufacturershouldbeconsultedregardingsectionsandsizesavailableincoils,producedtoachemicalcomposition.1.3Someapplicationsmayrequiresuperiorsurfacequality,orspecialchemicalrestrictions,metallurgicalcharacteristics,heattreatment,orsurfacefinisheswhichthepurchasermayobtainbydesignatingoneormoreoftheavailableSupplemen-taryRequirements.2.ReferencedDocuments2.1ASTMStandards:2A29/A29MSpecificationforSteelBars,CarbonandAlloy,Hot-Wrought,GeneralRequirementsforA304SpecificationforCarbonandAlloySteelBarsSubjecttoEnd-QuenchHardenabilityRequirementsA400PracticeforSteelBars,SelectionGuide,Composition,andMechanicalPropertiesE112TestMethodsforDeterminingAverageGrainSizeE381MethodofMacroetchTestingSteelBars,Billets,Blooms,andForgingsE527PracticeforNumberingMetalsandAlloysintheUnifiedNumberingSystem(UNS)3.OrderingInformation3.1Ordersunderthisspecificationshouldincludethefol-lowingasrequiredtodescribeadequatelythedesiredmaterial:3.1.1Quantity(weightornumberofbars),3.1.2Nameofmaterial(hot-wroughtalloysteelbars),3.1.3Dimensions,3.1.4ASTMdesignation,3.1.5Deoxidationpractice(see5.3),3.1.6Gradedesignationorchemicalcompositionlimits(see6.1andTable1...