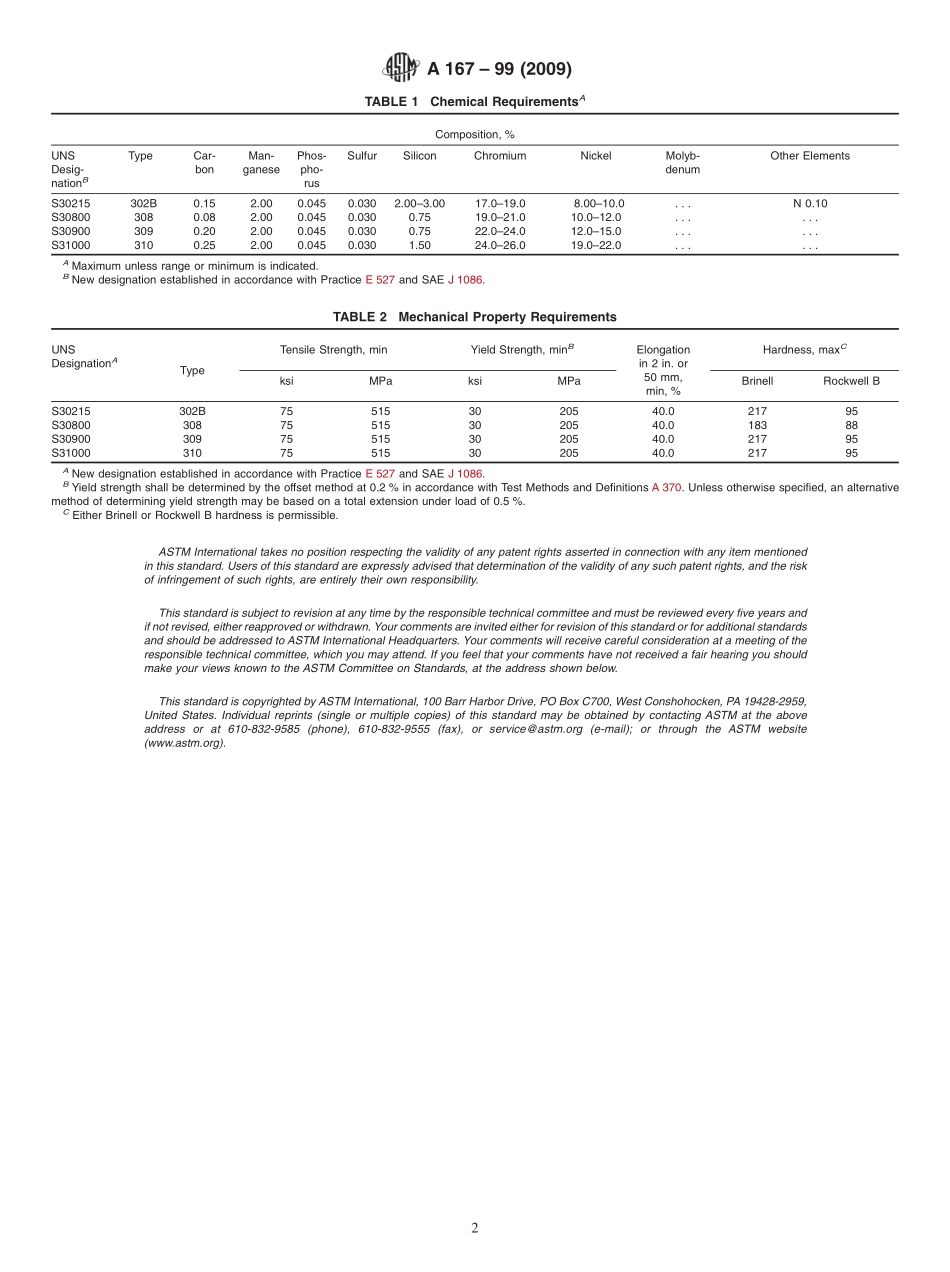

Designation:A167–99(Reapproved2009)StandardSpecificationforStainlessandHeat-ResistingChromium-NickelSteelPlate,Sheet,andStrip1ThisstandardisissuedunderthefixeddesignationA167;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheDepartmentofDefense.1.Scope1.1Thisspecificationcoversstainlessandheat-resistingchromium-nickelsteelplate,sheet,andstrip.1.2Thevaluesstatedininch-poundunitsaretoberegardedasthestandard.NOTE1—GradesthatwerepreviouslycoveredinbothSpecificationsA167andA240/A240MhavebeenremovedfromthisspecificationandmaynowbesuppliedandpurchasedincompliancewithSpecificationA240/A240M.ThechemicalandmechanicalpropertyrequirementsofthesegradeswereidenticalinSpecificationsA167andA240/A240MatthetimeofremovalfromSpecificationA167.2.ReferencedDocuments2.1ASTMStandards:2A240/A240MSpecificationforChromiumandChromium-NickelStainlessSteelPlate,Sheet,andStripforPressureVesselsandforGeneralApplicationsA370TestMethodsandDefinitionsforMechanicalTestingofSteelProductsA480/A480MSpecificationforGeneralRequirementsforFlat-RolledStainlessandHeat-ResistingSteelPlate,Sheet,andStripE527PracticeforNumberingMetalsandAlloysintheUnifiedNumberingSystem(UNS)2.2SAEStandard:3J1086NumberingMetalsandAlloys(UNS)3.ChemicalComposition3.1ThesteelshallconformtotherequirementsastochemicalcompositionspecifiedinTable1,andshallconformtoapplicablerequirementsspecifiedinSpecificationA480/A480M.4.MechanicalProperties4.1ThematerialshallconformtothemechanicalpropertiesspecifiedinTable2.5.GeneralRequirements5.1Thefollowingrequirementsforordersformaterialfurnishedunderthisspecificationshallconformtotheappli-cablerequirementsofthecurrenteditionofSpecificationA480/A480M.5.1.1Definitions,5.1.2Generalrequirementsfordelivery,5.1.3Orderinginformation,5.1.4Process,5....