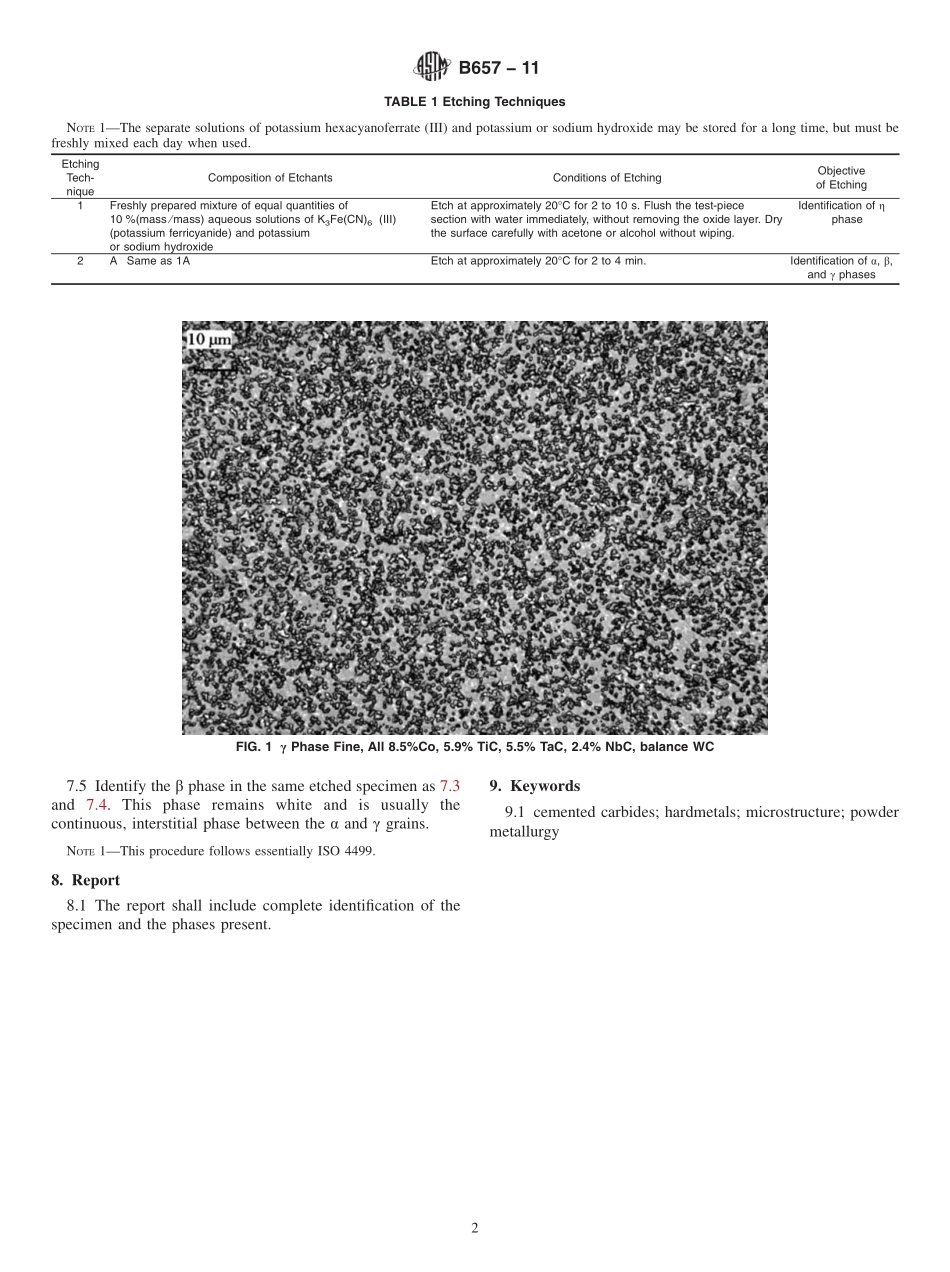

Designation:B657−11StandardGuideforMetallographicIdentificationofMicrostructureinCementedCarbides1ThisstandardisissuedunderthefixeddesignationB657;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope*1.1Thisguidecoversapparatusandproceduresforthemetallographicidentificationofmicrostructuresincementedcarbides.1.2Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.Precautionsapply-ingtouseofhazardouslaboratorychemicalsshouldbeobservedforchemicalsspecifiedinTable1.2.ReferencedDocuments2.1ASTMStandards:2B665GuideforMetallographicSamplePreparationofCe-mentedTungstenCarbides2.2ISOStandard:3ISO4499Hardmetals—MetallographicDeterminationofMicrostructure3.Terminology3.1DefinitionsofSymbols:SymbolDefinitionαphasetungstencarbideβphasebinder(forexample,Co,Ni,Fe)γphasecarbideofacubiclattice(forexample,TiC,TaC,NbC)thatmaycontainothercarbides(forexample,WC)insolidsolutionη-typephasesmultiplecarbidesoftungstenandatleastonemetalofthebinder4.SignificanceandUse4.1Themicrostructureofacementedcarbideaffectsthematerial’smechanicalandphysicalproperties.Thisguideisnotintendedtobeusedasaspecificationforcarbidegrades.Producersandusersmayusethemicrostructuralinformationasaguideindevelopingtheirownspecifications.5.Apparatus5.1MetallographicMicroscopecapableofmagnificationsupto1500times.5.2Ordinarymetallurgicallaboratoryequipment.5.3EquipmentforspecimenpreparationasoutlinedinGuideB665.6.SpecimenPreparation6.1AsuitableprocedureisdescribedinGuideB665.7.Procedure7.1Examinethemicrostructurebygradualdevelopmentofthephasesbyetching.ExamplesofsuitableetchingtechniquesaregiveninTable1.Examplesoftheappe...