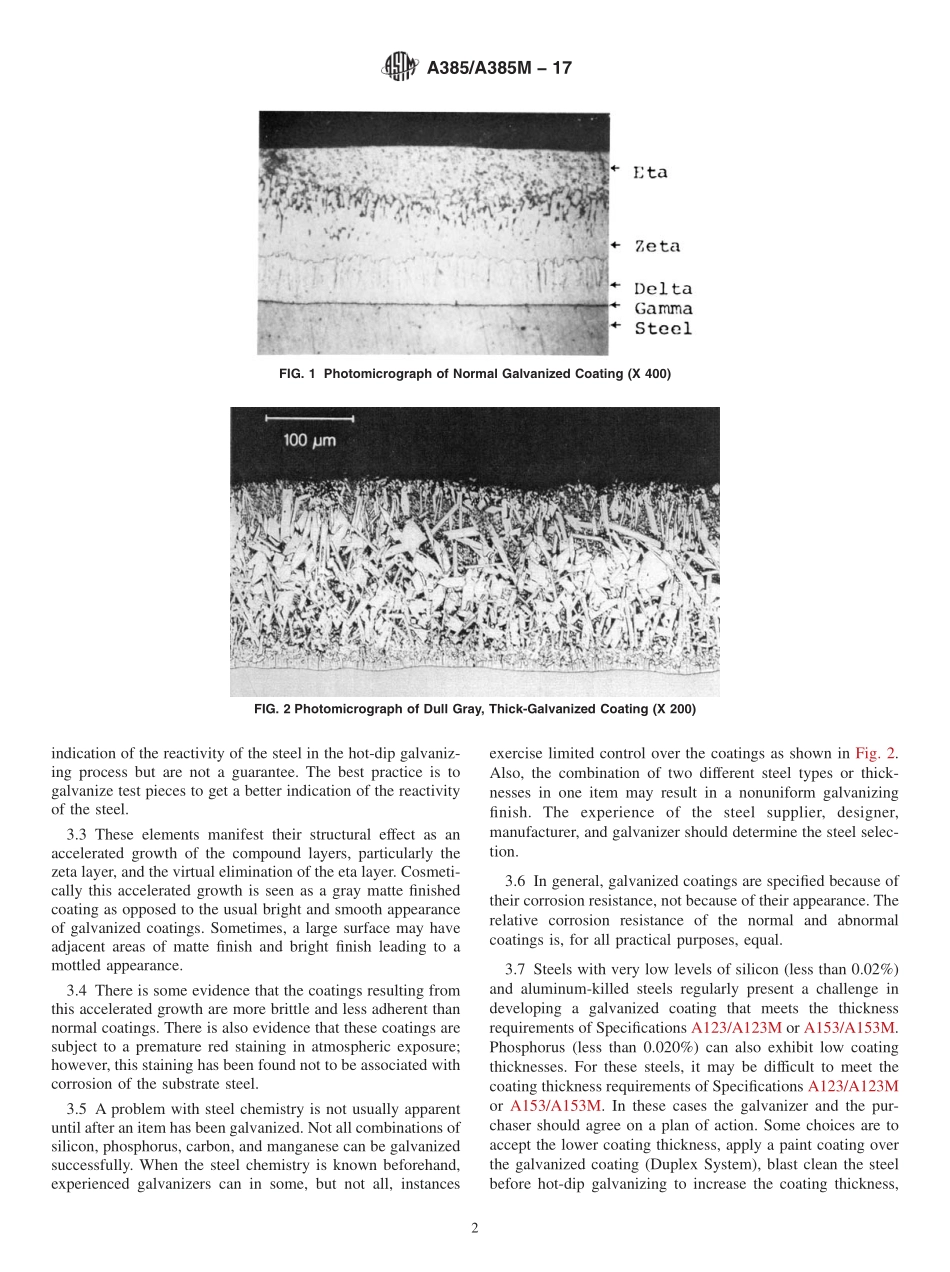

Designation:A385/A385M−17StandardPracticeforProvidingHigh-QualityZincCoatings(Hot-Dip)1ThisstandardisissuedunderthefixeddesignationA385/A385M;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope*1.1Thispracticecoverstheprecautionsthatshouldbetakentoobtainhigh-qualityhot-dipgalvanizedcoatings.1.2Whereexperienceonaspecificproductindicatesarelaxingofanyprovision,themutuallyacceptablechangeshallbeamatterforagreementbetweenthemanufacturerandpurchaser.1.3Thisspecificationisapplicabletoordersineitherinch-poundunits(asA385)orinSIunits(asA385M).Inch-poundunitsandSIunitsarenotnecessarilyexactequivalents.Withinthetextofthisspecificationandwhereappropriate,SIunitsareshowninbrackets.Eachsystemshallbeusedindependentlyoftheotherwithoutcombiningvaluesinanyway.1.4Thisinternationalstandardwasdevelopedinaccor-dancewithinternationallyrecognizedprinciplesonstandard-izationestablishedintheDecisiononPrinciplesfortheDevelopmentofInternationalStandards,GuidesandRecom-mendationsissuedbytheWorldTradeOrganizationTechnicalBarrierstoTrade(TBT)Committee.2.ReferencedDocuments2.1ASTMStandards:2A123/A123MSpecificationforZinc(Hot-DipGalvanized)CoatingsonIronandSteelProductsA143/A143MPracticeforSafeguardingAgainstEmbrittle-mentofHot-DipGalvanizedStructuralSteelProductsandProcedureforDetectingEmbrittlementA153/A153MSpecificationforZincCoating(Hot-Dip)onIronandSteelHardwareA384/A384MPracticeforSafeguardingAgainstWarpageandDistortionDuringHot-DipGalvanizingofSteelAssembliesA563SpecificationforCarbonandAlloySteelNuts2.2AmericanInstituteofSteelConstruction(AISC)Docu-ments:3SteelConstructionManual3.SteelSelection3.1Theproductionofagalvanizedcoatinghasasitsbasisthemetallurgicalreactionbetweenthesteelandthemoltenzinc,resultingintheformationofseveraliron-zinccompoundlayers,forexample,gamma(notalway...