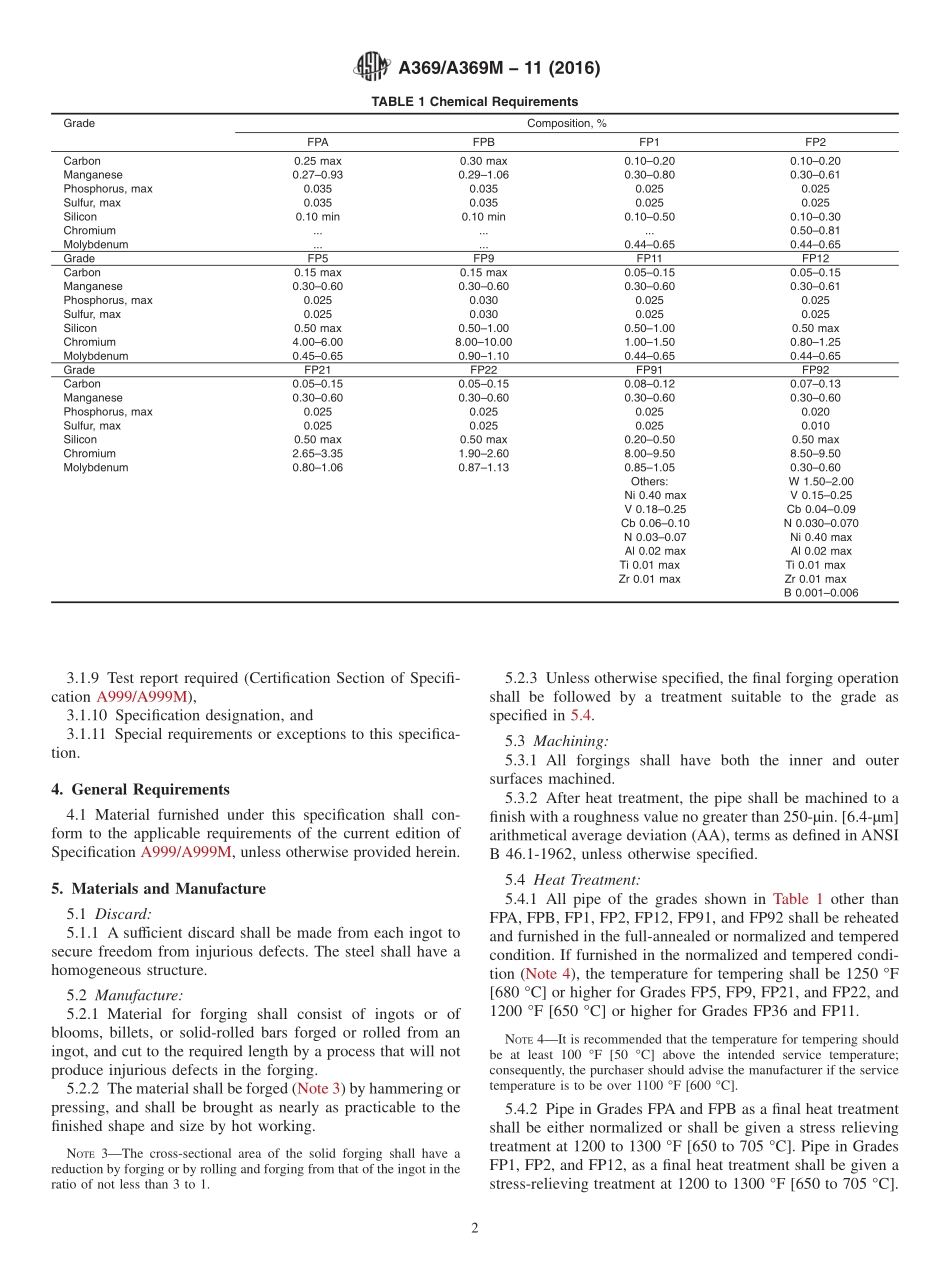

Designation:A369/A369M−11(Reapproved2016)StandardSpecificationforCarbonandFerriticAlloySteelForgedandBoredPipeforHigh-TemperatureService1ThisstandardisissuedunderthefixeddesignationA369/A369M;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thisspecification2coversheavy-wallcarbonandalloysteelpipe(Note1)madefromturnedandboredforgingsandisintendedforhigh-temperatureservice.Pipeorderedunderthisspecificationshallbesuitableforbendingandotherformingoperationsandforfusionwelding.Selectionwilldependondesign,serviceconditions,mechanicalpropertiesandhigh-temperaturecharacteristics.NOTE1—Theuseoftheword“pipe”throughouttheseveralsectionsofthisspecificationisusedinthebroadsenseandintendedtomeanpipeheaders,orleads.NOTE2—ThedimensionlessdesignatorNPS(nominalpipesize)hasbeensubstitutedinthisstandardforsuchtraditionaltermsas“nominaldiameter,”“size,”and“nominalsize.”1.2Severalgradesofferriticsteelsarecovered.TheircompositionsaregiveninTable1.1.3Supplementaryrequirements(S1toS6)ofanoptionalnatureareprovided.Thesesupplementaryrequirementscallforadditionalteststobemade,andwhendesiredshallbesostatedintheorder,togetherwiththenumberofsuchtestsrequired.1.4ThevaluesstatedineitherSIunitsorinch-poundunitsaretoberegardedseparatelyasstandard.Withinthetext,theSIunitsareshowninbrackets.Thevaluesstatedineachsystemmaynotbeexactequivalents;therefore,eachsystemshallbeusedindependentlyoftheother.Combiningvaluesfromthetwosystemsmayresultinnon-conformancewiththestandard.Theinch-poundunitsshallapplyunlessthe“M”designationofthisspecificationisspecifiedintheorder.2.ReferencedDocuments2.1ASTMStandards:3A999/A999MSpecificationforGeneralRequirementsforAlloyandStainlessSteelPipeE290TestMethodsforBendTestingofMaterialforDuctil-ityE381MethodofMacroetchTestingSteelBars,Billets,Blooms...