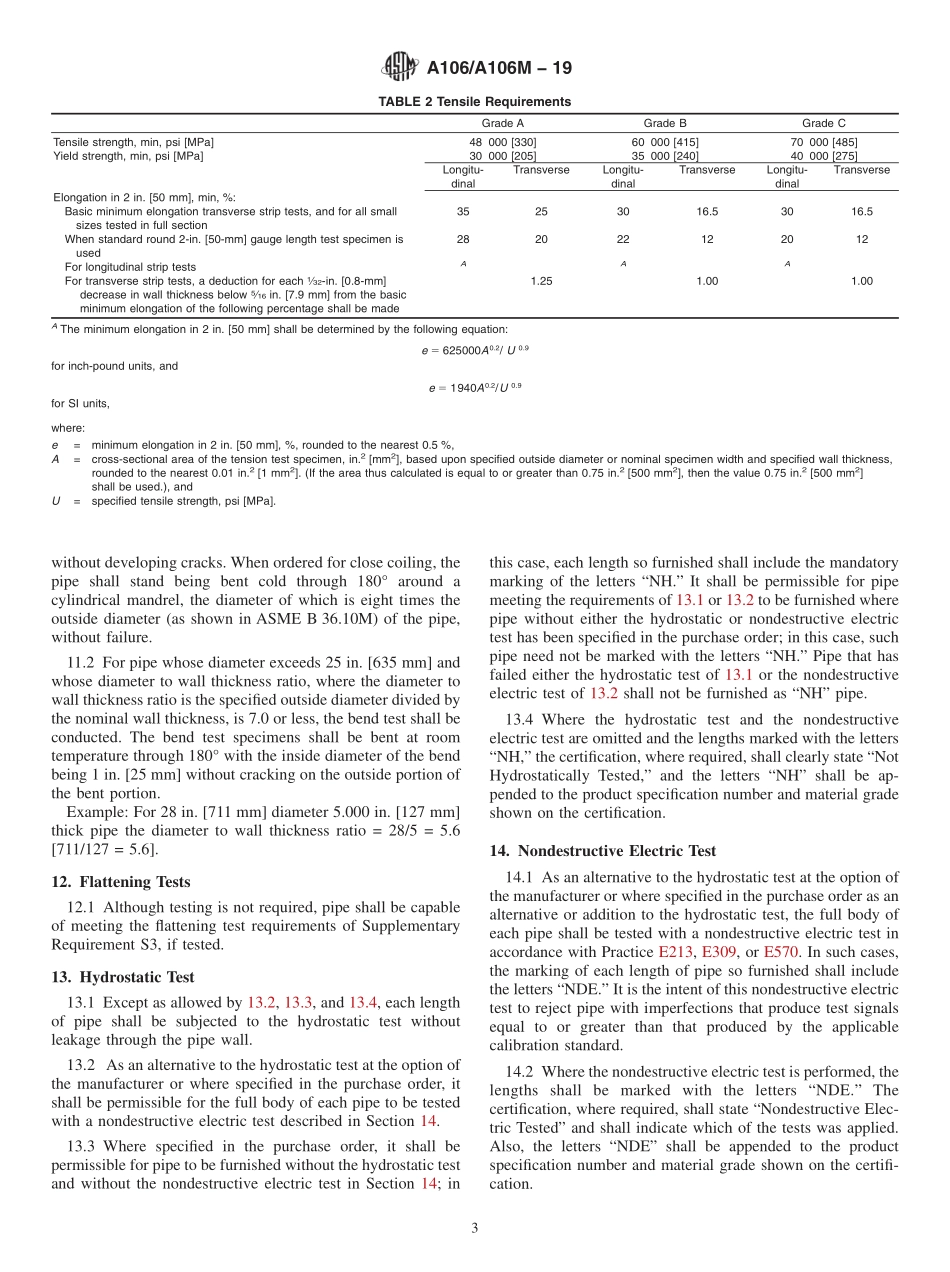

Designation:A106/A106M−19UsedinUSDOE-NEstandardsStandardSpecificationforSeamlessCarbonSteelPipeforHigh-TemperatureService1ThisstandardisissuedunderthefixeddesignationA106/A106M;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope*1.1Thisspecification2coversseamlesscarbonsteelpipeforhigh-temperatureservice(Note1)inNPS1⁄8toNPS48[DN6toDN1200](Note2)inclusive,withnominal(average)wallthicknessasgiveninASMEB36.10M.Itshallbepermissibletofurnishpipehavingotherdimensionsprovidedsuchpipecomplieswithallotherrequirementsofthisspecification.Pipeorderedunderthisspecificationshallbesuitableforbending,flanging,andsimilarformingoperations,andforwelding.Whenthesteelistobewelded,itispresupposedthataweldingproceduresuitabletothegradeofsteelandintendeduseorservicewillbeutilized.NOTE1—Itissuggested,considerationbegiventopossiblegraphitiza-tion.NOTE2—ThedimensionlessdesignatorNPS(nominalpipesize)[DN(diameternominal)]hasbeensubstitutedinthisstandardforsuchtraditionaltermsas“nominaldiameter,”“size,”and“nominalsize.”1.2Supplementaryrequirementsofanoptionalnatureareprovidedforseamlesspipeintendedforuseinapplicationswhereasuperiorgradeofpipeisrequired.Thesesupplemen-taryrequirementscallforadditionalteststobemadeandwhendesiredshallbesostatedintheorder.1.3ThevaluesstatedineitherSIunitsorinch-poundunitsaretoberegardedseparatelyasstandard.Thevaluesstatedineachsystemmaynotbeexactequivalents;therefore,eachsystemshallbeusedindependentlyoftheother.Combiningvaluesfromthetwosystemsmayresultinnon-conformancewiththestandard.1.4Thefollowingprecautionarycaveatpertainsonlytothetestmethodportion,Sections11,12,and13ofthisspecifica-tion:Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappropriatesafet...