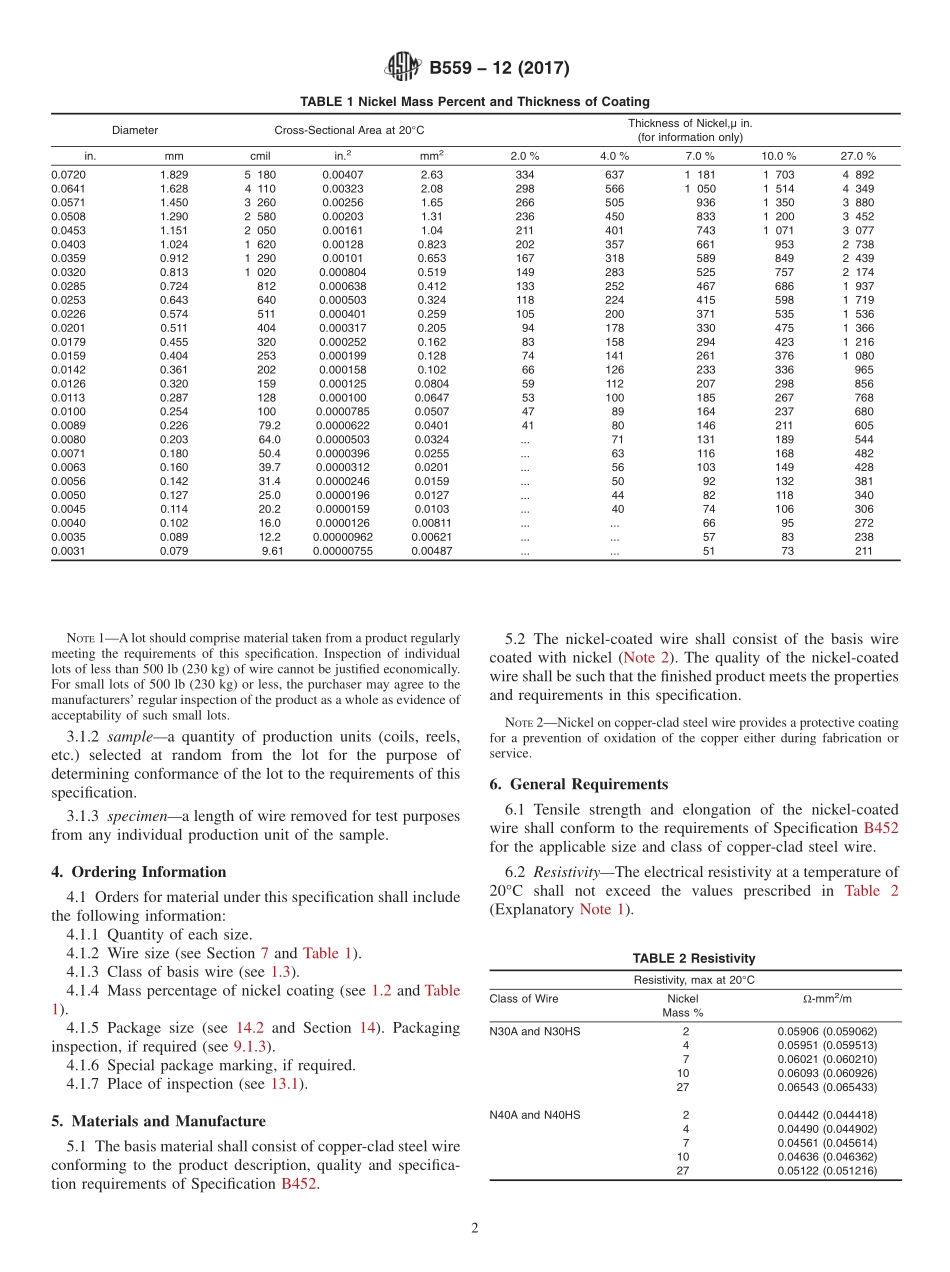

Designation:B559−12(Reapproved2017)StandardSpecificationforNickel-Coated,Copper-CladSteelWireforElectronicApplication1ThisstandardisissuedunderthefixeddesignationB559;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheU.S.DepartmentofDefense.1.Scope1.1Thisspecificationcoversnickel-coated,round,copper-cladsteelwireforelectronicapplication.1.2Nickelcoatingsinmasspercentagesofthetotalmassofthecoatedwireareasfollows:2,4,7,10,and27%.Nickel-coatedwirehavingdifferentminimummasspercent-agesofnickelmaybeobtainedbymutualagreementbetweenthemanufacturerandthepurchaser.Forinformationpurposes,thethicknessofcoatinginmicroinchesprovidedbythepercentageslistedaboveisshowninTable1.1.3Fourclassesofnickel-coated,copper-cladsteelwirearecoveredasfollows:1.3.1ClassN30HS—Nominal30%conductivity,harddrawn.1.3.2ClassN30A—Nominal30%conductivity,annealed.1.3.3ClassN40HS—Nominal40%conductivity,harddrawn.1.3.4ClassN40A—Nominal40%conductivity,annealed.1.4Thevaluesstatedininch-poundunitsaretoberegardedasstandard.ThevaluesgiveninparenthesesaremathematicalconversionstoSIunitsthatareprovidedforinformationonlyandarenotconsideredstandard.1.4.1Exception—TheSIvaluesforresistivityaretoberegardedasstandard.1.5Thefollowingsafetyhazardscaveatpertainsonlytothetestmethoddescribedinthisspecification.Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappropriatesafetyandhealthpracticesanddeterminetheapplicabilityofregulatorylimitationspriortouse.(Warning—Considerationshouldbegiventotoxicityandflammabilitywhenselectingsolventcleaners.)1.6Thisinternationalstandardwasdevelopedinaccor-dancewithinternationallyrecognizedprinciplesonstandard-izationestablishedintheDecisionon...