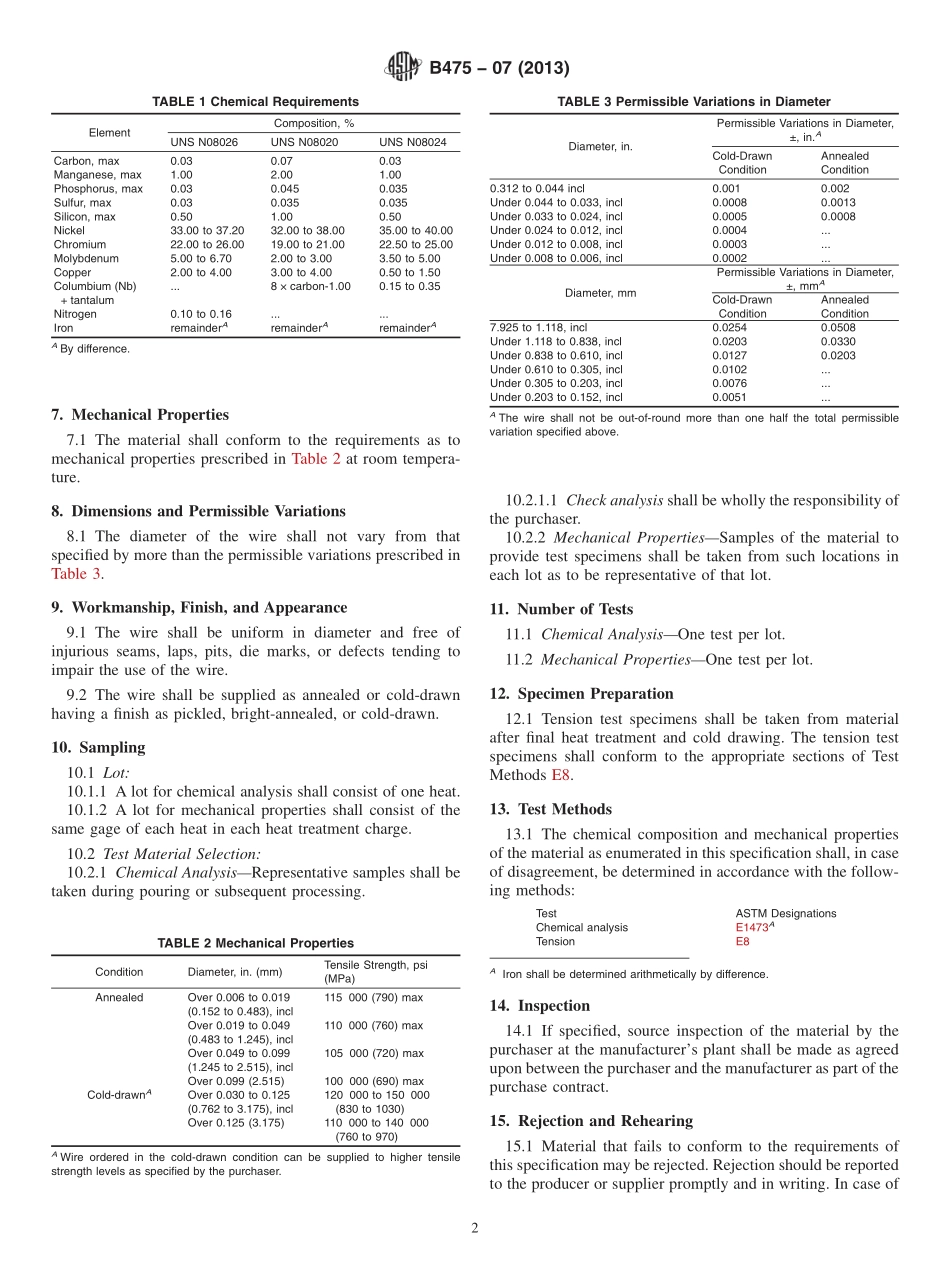

Designation:B475−07(Reapproved2013)StandardSpecificationforUNSN08020,UNSN08024,andUNSN08026NickelAlloyRoundWeavingWire1ThisstandardisissuedunderthefixeddesignationB475;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1ThisspecificationcoversUNSN08020,UNSN08026,andUNSN08024roundweavingwire.NOTE1—Weavingwireiscustomarilynotwelded.Forapplicationsinvolvingweldinginwhichthewireshouldbestabilizedagainstlossofcorrosionresistance,thepurchasershouldrefertoSpecificationB473.1.2Thevaluesstatedininch-poundunitsaretoberegardedasstandard.ThevaluesgiveninparenthesesaremathematicalconversionstoSIunitsthatareprovidedforinformationonlyandarenotconsideredstandard.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.ItistheresponsibilityoftheuserofthisstandardtobecomefamiliarwithallhazardsincludingthoseidentifiedintheappropriateMaterialSafetyDataSheet(MSDS)forthisproduct/materialasprovidedbythemanufacturer,toestablishappropriatesafetyandhealthpractices,anddeterminetheapplicabilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2B473SpecificationforUNSN08020,UNSN08024,andUNSN08026NickelAlloyBarandWireB880SpecificationforGeneralRequirementsforChemicalCheckAnalysisLimitsforNickel,NickelAlloysandCobaltAlloysE8TestMethodsforTensionTestingofMetallicMaterialsE1473TestMethodsforChemicalAnalysisofNickel,Cobalt,andHigh-TemperatureAlloys3.Terminology3.1DefinitionsofTermsSpecifictoThisStandard:3.1.1weavingwire,n—termweavingwireasusedinthisspecificationshallbeunderstoodtocoverroundwireintendedespeciallyforweaving.4.OrderingInformation4.1Itistheresponsibilityofthepurchasertospecifyallrequirementsthatarenecessaryforthesafeandsatisfactoryperformanceofmaterialorderedunderthisspecification.Examplesofsuchrequirementsinclude,but...