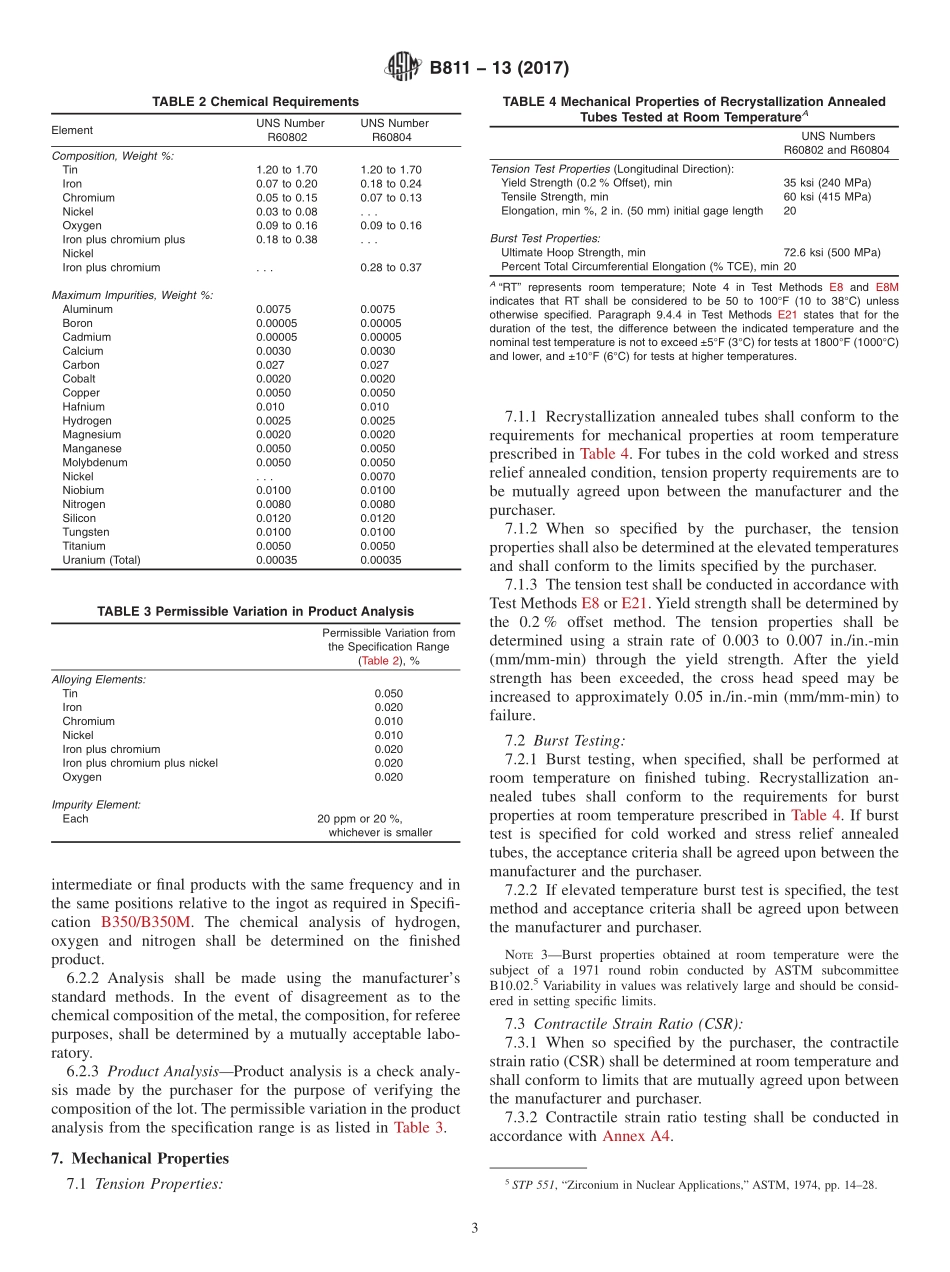

Designation:B811−13(Reapproved2017)StandardSpecificationforWroughtZirconiumAlloySeamlessTubesforNuclearReactorFuelCladding1ThisstandardisissuedunderthefixeddesignationB811;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thisspecificationcoversseamlesswroughtzirconium-alloytubesfornuclearfuelcladdingapplication,intheoutsidediameter(OD)sizerangeof0.200in.(5.1mm)to0.650in.(16.5mm)andwallthicknessrangeof0.010in.(0.25mm)to0.035in.(0.89mm).1.2Twogradesofreactorgradezirconiumalloysaredescribed.1.2.1ThepresentUNSnumbersdesignatedforthetwogradesaregiveninTable1.1.3Unlessasingleunitisused,forexamplecorrosionmassgaininmg/dm2,thevaluesstatedineitherinch-poundorSIunitsaretoberegardedseparatelyasstandard.Thevaluesstatedineachsystemarenotexactequivalents;thereforeeachsystemmustbeusedindependentlyoftheother.SIvaluescannotbemixedwithinch-poundvalues.1.4Thefollowingprecautionarycaveatpertainsonlytothetestmethodportionsofthisspecification:Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappropriatesafety,health,andenviron-mentalpracticesanddeterminetheapplicabilityofregulatorylimitationspriortouse.1.5Thisinternationalstandardwasdevelopedinaccor-dancewithinternationallyrecognizedprinciplesonstandard-izationestablishedintheDecisiononPrinciplesfortheDevelopmentofInternationalStandards,GuidesandRecom-mendationsissuedbytheWorldTradeOrganizationTechnicalBarrierstoTrade(TBT)Committee.2.ReferencedDocuments2.1ASTMStandards:2B350/B350MSpecificationforZirconiumandZirconiumAlloyIngotsforNuclearApplicationB353SpecificationforWroughtZirconiumandZirconiumAlloySeamlessandWeldedTubesforNuclearService(ExceptNuclearFuelCladding)E8TestMethodsforTensionTestingofMetallicMaterialsE8MTestMethodsforTe...