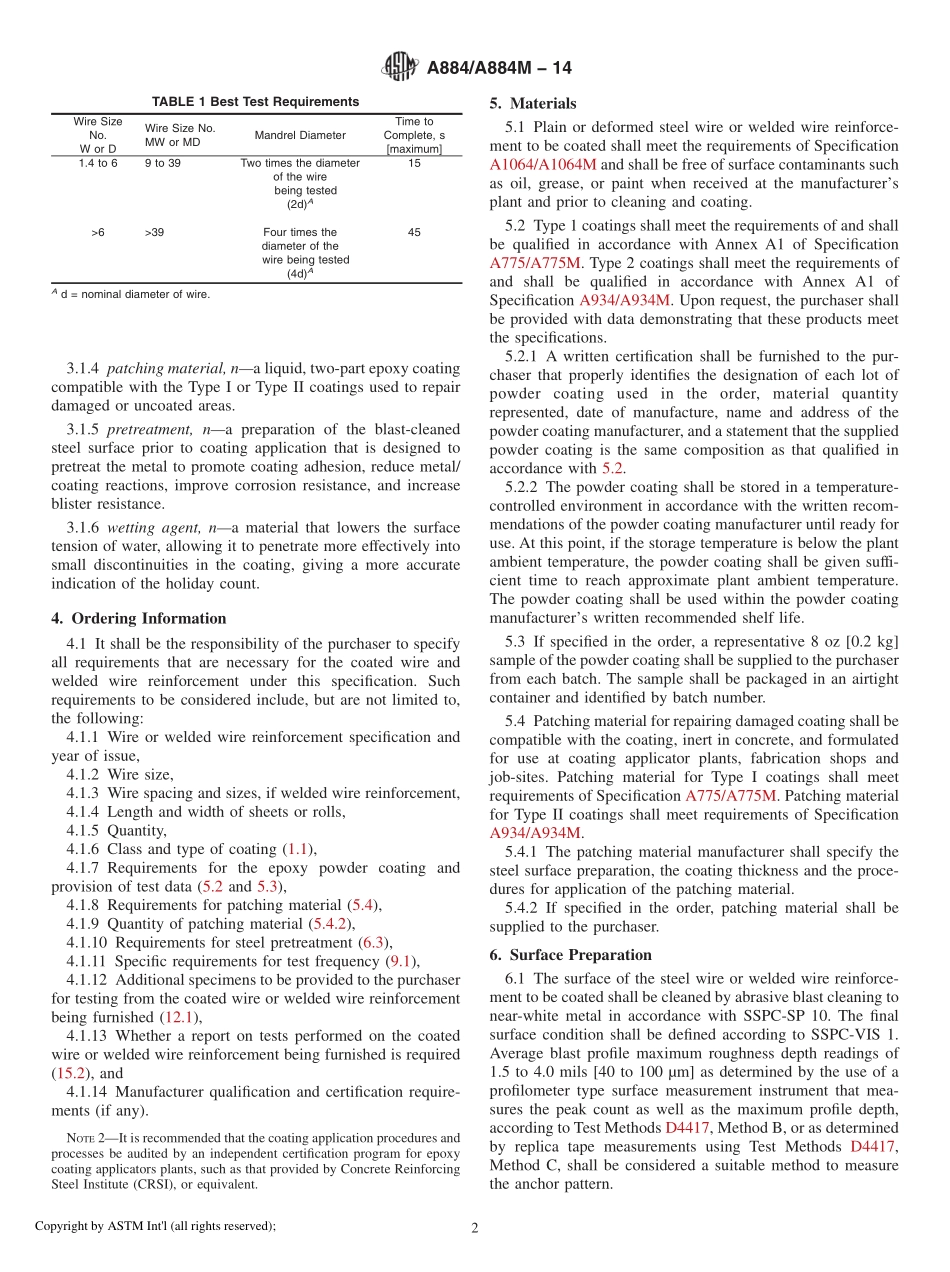

Designation:A884/A884M−14StandardSpecificationforEpoxy-CoatedSteelWireandWeldedWireReinforcement1ThisstandardisissuedunderthefixeddesignationA884/A884M;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope*1.1Thisspecificationcoversplainanddeformedsteelwireandplainanddeformedsteelweldedwirereinforcementwithprotectiveepoxycoating.AClassAminimumcoatingthick-nessisrequiredforwireandweldedwirereinforcementintendedforuseinconcreteandmasonry.AClassBminimumcoatingthicknessisrequiredforwireandweldedwirerein-forcementintendedforuseinmechanicallystabilizedearthapplications.AType1coatingisafusion-bondedepoxycoatingthathasbeenformulatedtobesufficientlyflexibletoallowbendingofthecoatedwireorweldedwirereinforce-ment.AType2coatingisafusion-bondedepoxycoatingthathasnotbeendesignedtobesufficientlyflexibletoallowbendingofthecoatedwireorweldedwirereinforcement.NOTE1—Thecoatingapplicatorisidentifiedthroughoutthisspecifica-tionasthemanufacturer.1.2Thisspecificationisapplicableforordersineitherinch-poundunits(asSpecificationA884)orSIunits(asSpecificationA884M).1.3Thevaluesstatedineitherinch-poundorSIunitsaretoberegardedseparatelyasstandard.Withinthetext,theSIunitsareshowninbrackets.Thevaluesstatedineachsystemmaynotbeexactequivalents;therefore,eachsystemshallbeusedindependentlyoftheotherexceptasspecificallynotedinTable1.Combiningvaluesfromthetwosystemsmayresultinnon-conformancewiththisspecification.1.4Thisspecificationdoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisspecificationtoestablishappropriatesafetyandhealthpracticesanddeterminetheapplicabilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2A775/A775MSpecificationforEpoxy-CoatedSteelRein-forcingBarsA934/A934MSpecificationforEpoxy-Coate...