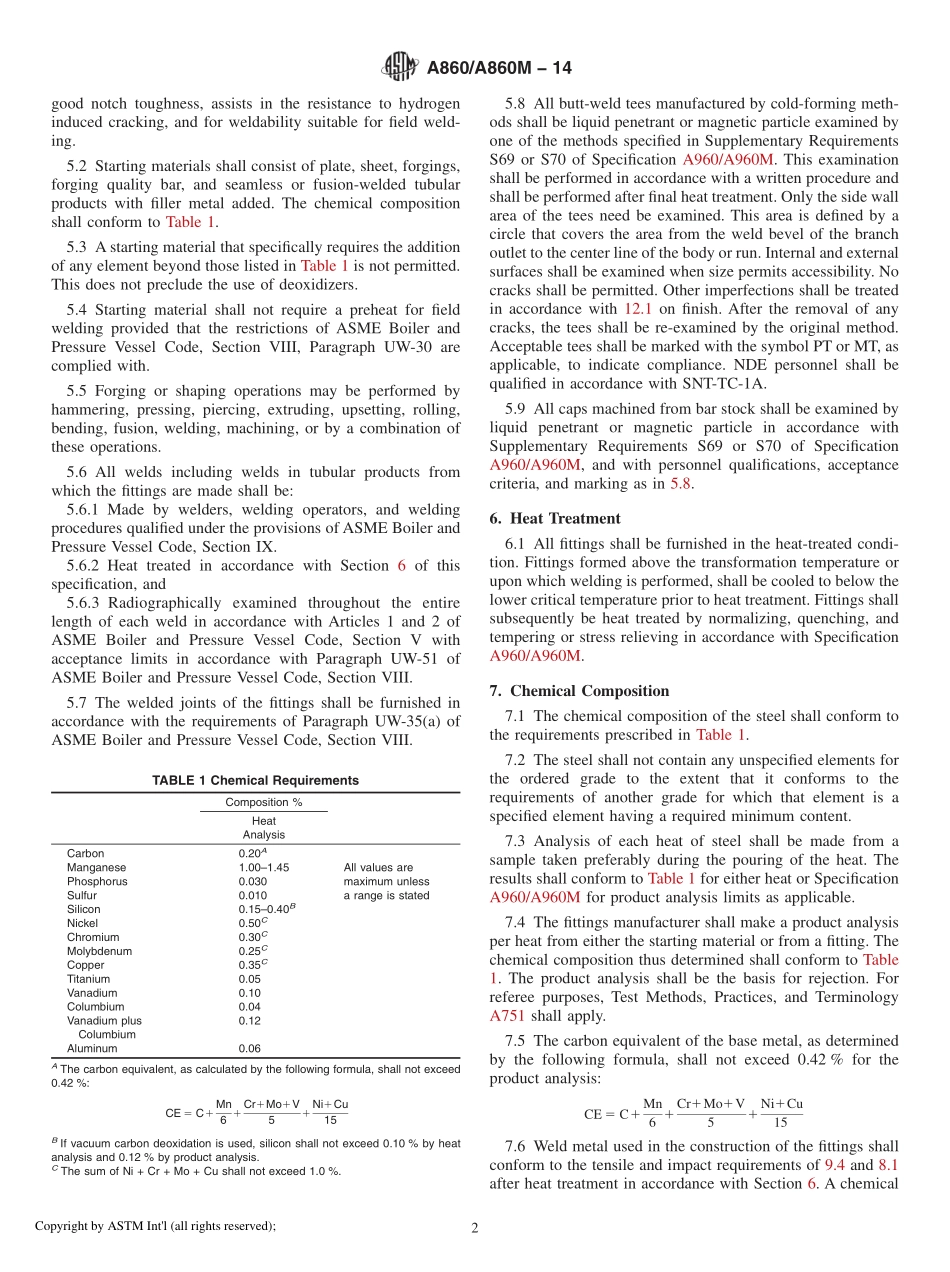

Designation:A860/A860M−14StandardSpecificationforWroughtHigh-StrengthFerriticSteelButt-WeldingFittings1ThisstandardisissuedunderthefixeddesignationA860/A860M;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope*1.1Thisspecificationcoverswroughthigh-strengthferriticsteelbutt-weldingfittingsofseamlessandelectricfusion-weldedconstructioncoveredbythelatestrevisionsofASMEB16.9andMSS-SP-75.Butt-weldingfittingsdifferingfromtheseASMEandMSSstandardsshallbefurnishedinaccor-dancewithSupplementaryRequirementS58ofSpecificationA960/A960M.Thesefittingsareforuseinhigh-pressuregasandoiltransmissionanddistributionsystems.1.2Optionalsupplementaryrequirementsareprovidedforfittingswhenagreaterdegreeofexaminationisdesired.Oneormoreofthesupplementaryrequirementsmaybespecifiedintheorder.1.3Thisspecificationdoesnotcovercast-weldingfittingsorfittingsmachinedfromcastings.1.4ThevaluesstatedineitherSIunitsorinch-poundunitsaretoberegardedseparatelyasstandard.Withinthetext,theSIunitsareshowninbrackets.Thevaluesstatedineachsystemmaynotbeexactequivalents;therefore,eachsystemshallbeusedindependentlyoftheother.Combiningvaluesfromthetwosystemsmayresultinnon-conformancewiththestandard.Unlesstheorderspecifiestheapplicable“M”speci-ficationdesignation(SIunits),thematerialshallbefurnishedtoinch-poundunits.2.ReferencedDocuments2.1ASTMStandards:2A751TestMethods,Practices,andTerminologyforChemi-calAnalysisofSteelProductsA960/A960MSpecificationforCommonRequirementsforWroughtSteelPipingFittings2.2ASMEStandards:3B16.9SteelButt-WeldingFittings2.3ASMEBoilerandPressureVesselCode:3SectionVSectionVIIIDivision1SectionIX2.4MSSStandards:4MSSSP-25TheStandardMarkingSystemofValves,Fittings,FlangesandUnionsMSS-SP-75SpecificationforHighTestWroughtButt-WeldingFittings2.5AmericanSocietyofNondestructiveTesting:5SN...