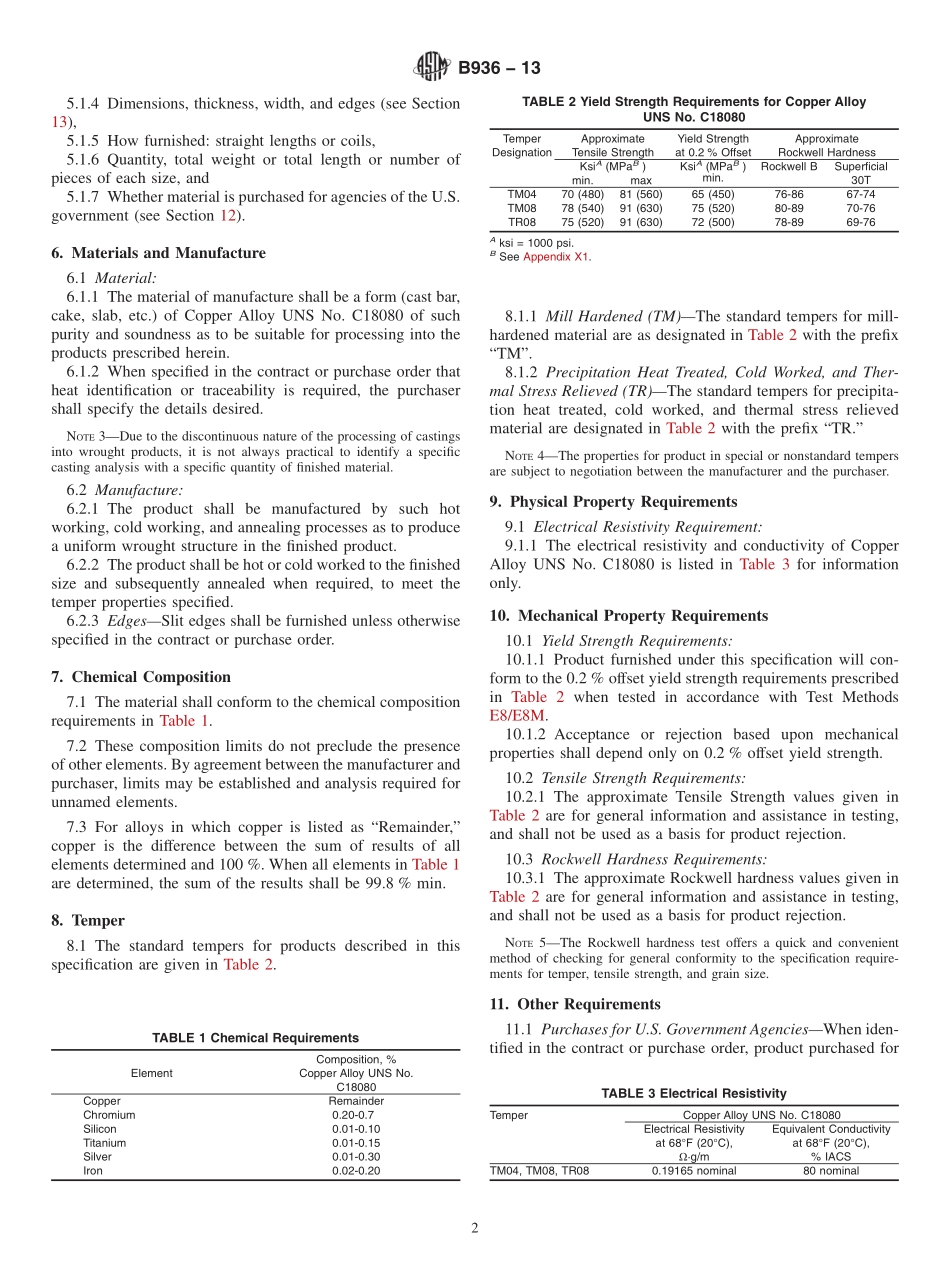

Designation:B936−13StandardSpecificationforCopper-Chromium-Iron-TitaniumAlloyPlate,Sheet,StripandRolledBar1ThisstandardisissuedunderthefixeddesignationB936;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope*1.1ThisspecificationestablishestherequirementsforCop-perAlloyUNSNo.C18080forplate,sheet,strip,androlledbar.NOTE1—SinceCopperAlloyUNSNo.C18080isfrequentlyusedinavarietyofapplicationswhereyieldstrengthandstress-corrosionresistancemaybecritical,itisrecommendedthatdrawingsorsamplesoftheparttobefabricatedanddetailsofapplicationbesubmittedforuseinestablishingtemperandtreatmentofmaterial.NOTE2—CopperAlloyUNSNo.C18080iscoveredbyapatent.Interestedpartiesareinvitedtosubmitinformationregardingtheidenti-ficationofanalternative(s)tothispatenteditemtoASTMInternationalheadquarters.Yourcommentswillreceivecarefulconsiderationatameetingoftheresponsibletechnicalcommittee,1whichyoumayattend.1.2Units—Thevaluesstatedininch-poundunitsaretoberegardedasstandard.ThevaluesgiveninparenthesesaremathematicalconversionstoSIunitsthatareprovidedforinformationonlyandarenotconsideredstandard.2.ReferencedDocuments2.1ASTMStandards:2B248SpecificationforGeneralRequirementsforWroughtCopperandCopper-AlloyPlate,Sheet,Strip,andRolledBarB248MSpecificationforGeneralRequirementsforWroughtCopperandCopper-AlloyPlate,Sheet,Strip,andRolledBar(Metric)B846TerminologyforCopperandCopperAlloysB950GuideforEditorialProceduresandFormofProductSpecificationsforCopperandCopperAlloysE8/E8MTestMethodsforTensionTestingofMetallicMa-terialsE62TestMethodsforChemicalAnalysisofCopperandCopperAlloys(PhotometricMethods)(Withdrawn2010)3E76TestMethodsforChemicalAnalysisofNickel-CopperAlloys(Withdrawn2003)3E478TestMethodsforChemicalAnalysisofCopperAlloysE1473TestMethodsforChemicalAnalysisofNickel,Cobalt,andHigh-Tempera...