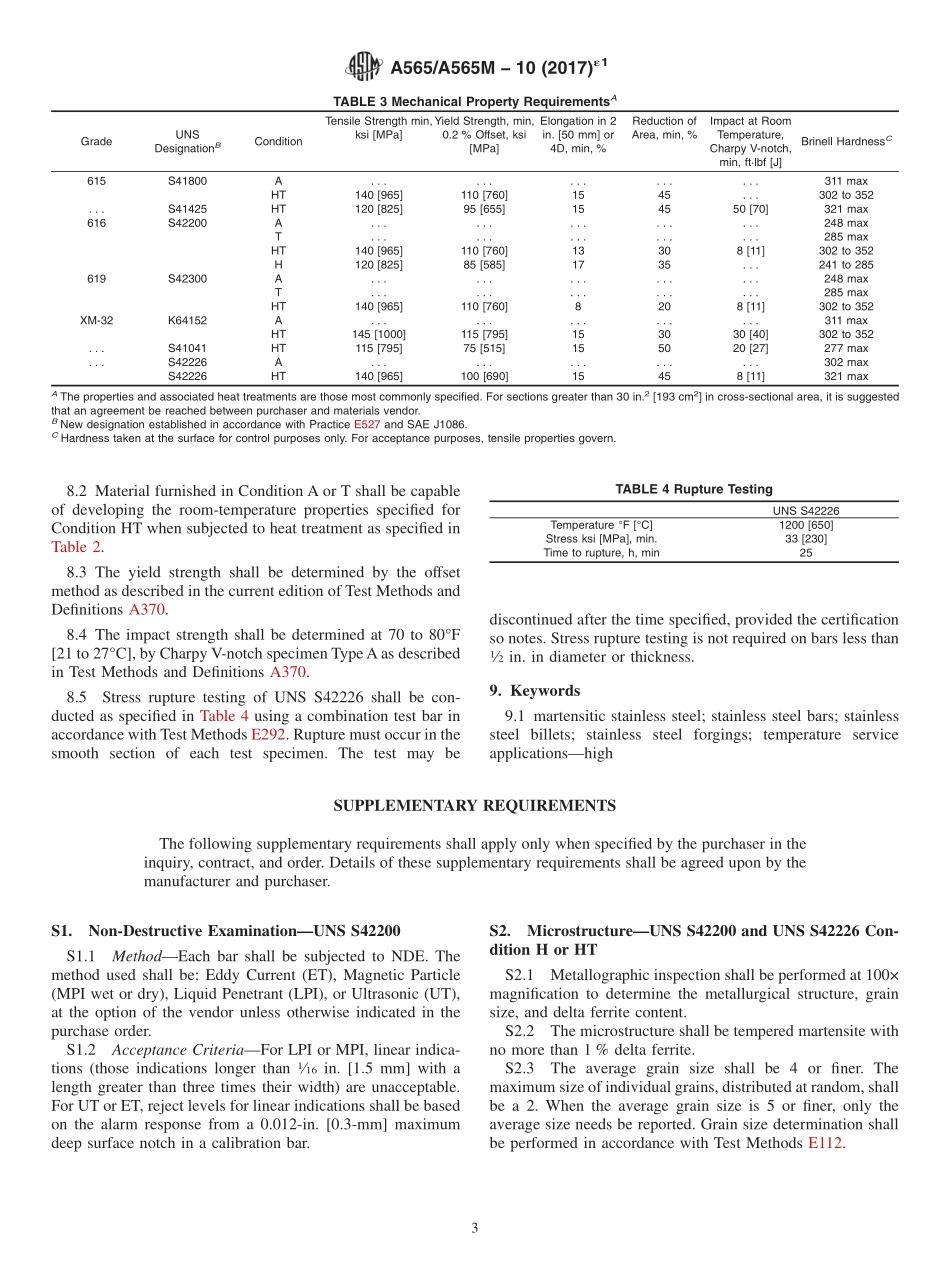

Designation:A565/A565M−10(Reapproved2017)´1StandardSpecificationforMartensiticStainlessSteelBarsforHigh-TemperatureService1ThisstandardisissuedunderthefixeddesignationA565/A565M;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheU.S.DepartmentofDefense.ε1NOTE—RevisedTable1editoriallytoshowcommonlyacceptedelementnameNiobium(formerlyColumbium)inMarch2017.1.Scope1.1Thisspecificationcovershot-finishedandcold-finishedmartensiticchromiumsteelbarsforhigh-temperatureservice.Themechanicalpropertiesaredevelopedbysuitableheattreatment,asindicatedforeachalloy.1.2Wherestrengthattemperatureisafactor,thesesteelsaregenerallylimitedtoamaximumservicetemperatureof1200°F[650°C].Foroxidation(scaling)resistanceandatlowstresses,thesesteelsareusefulto1450°F[790°C].1.3Thisspecificationisexpressedinbothinch-poundunitsandSIunits;however,unlessthepurchaseorderorcontractspecifiestheapplicableMspecificationdesignation(SIunits),theinch-poundunitsshallapply.Thevaluesstatedineitherinch-poundunitsorSIunitsaretoberegardedseparatelyasstandard.Withinthetext,theSIunitsareshowninbrackets.Thevaluesstatedineachsystemmaynotbeexactequivalents;therefore,eachsystemshallbeusedindependentlyoftheother.Combiningvaluesfromthetwosystemsmayresultinnoncon-formancewiththespecification.2.ReferencedDocuments2.1ASTMStandards:2A370TestMethodsandDefinitionsforMechanicalTestingofSteelProductsA484/A484MSpecificationforGeneralRequirementsforStainlessSteelBars,Billets,andForgingsA751TestMethods,Practices,andTerminologyforChemi-calAnalysisofSteelProductsA994GuideforEditorialProceduresandFormofProductSpecificationsforSteel,StainlessSteel,andRelatedAlloysE112TestMethodsforDeterminingAverageGrainSizeE292TestMethodsforConductingTime-for-RuptureNotchTensionTestsofMaterialsE...