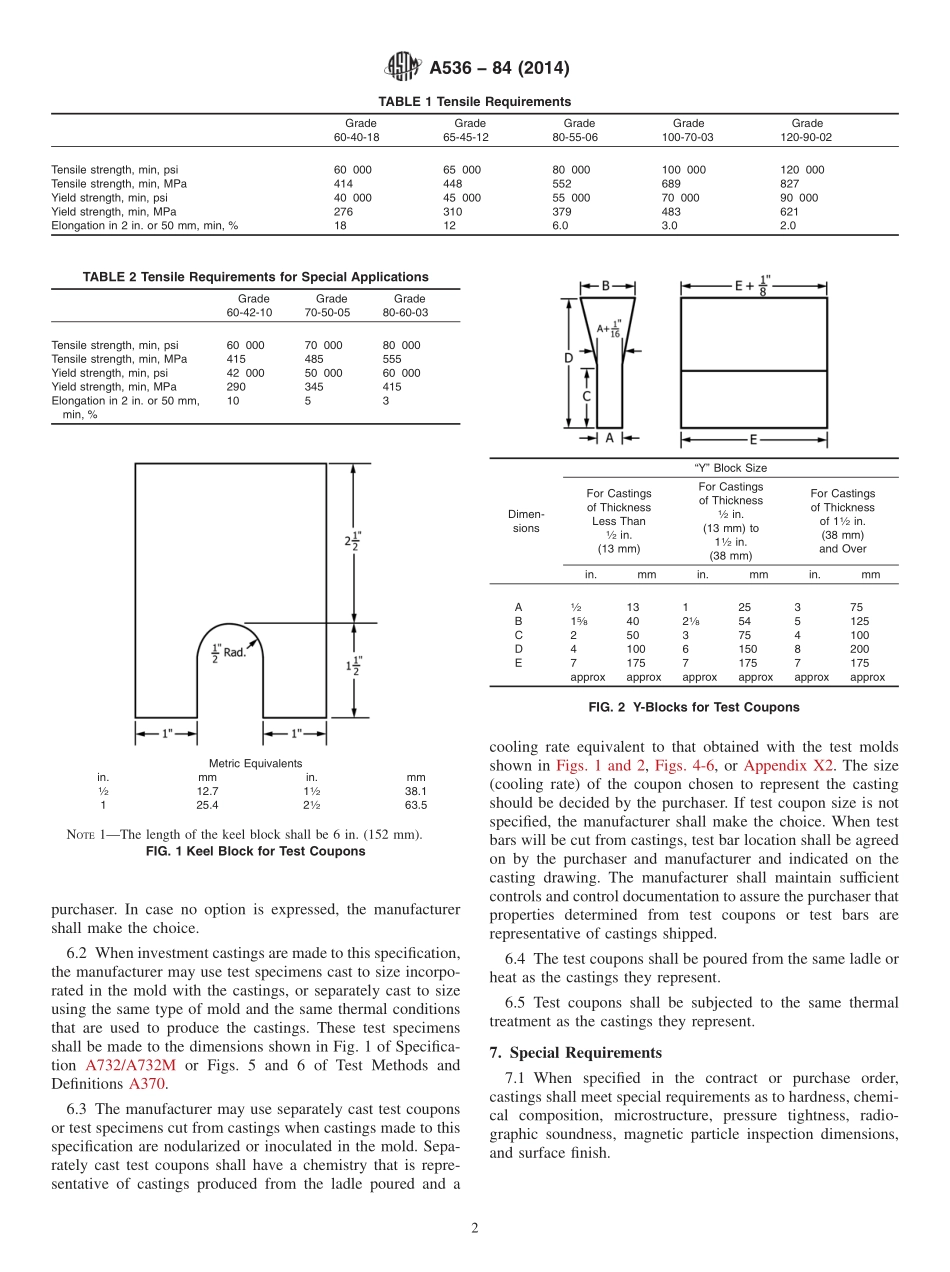

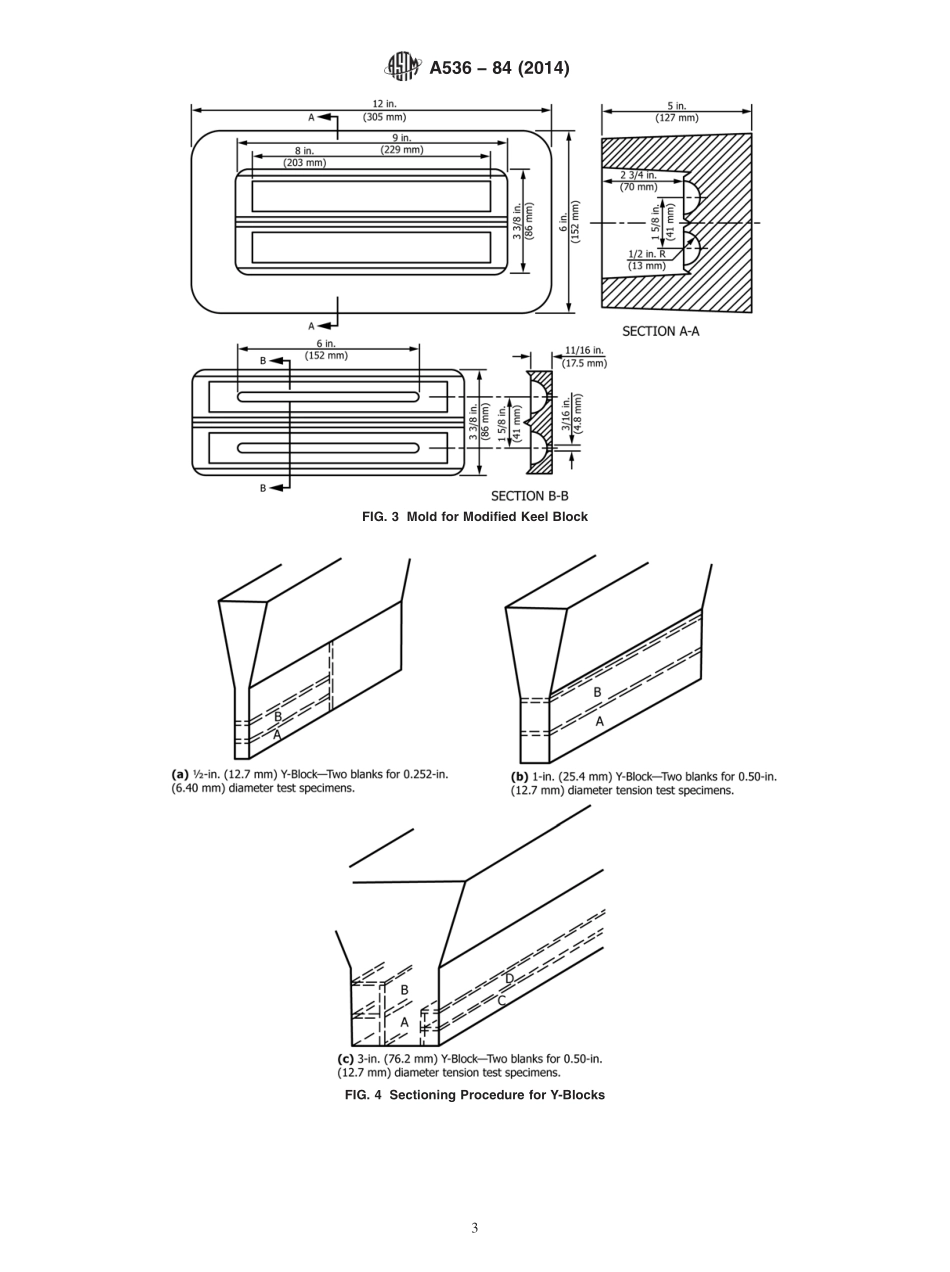

Designation:A536−84(Reapproved2014)StandardSpecificationforDuctileIronCastings1ThisstandardisissuedunderthefixeddesignationA536;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheU.S.DepartmentofDefense.1.Scope1.1Thisspecificationcoverscastingsmadeofductileiron,alsoknownasspheroidalornodulariron,thatisdescribedascastironwiththegraphitesubstantiallyspheroidalinshapeandessentiallyfreeofotherformsofgraphite,asdefinedinTerminologyA644.1.2Noprecisequantitativerelationshipcanbestatedbe-tweenthepropertiesoftheironinvariouslocationsofthesamecastingorbetweenthepropertiesofcastingsandthoseofatestspecimencastfromthesameiron(seeAppendixX1).1.3Thevaluesstatedininch-poundunitsaretoberegardedasstandard.ThevaluesgiveninparenthesesaremathematicalconversionstoSIunitsthatareprovidedforinformationonlyandarenotconsideredstandard.2.ReferencedDocuments2.1ASTMStandards:2A370TestMethodsandDefinitionsforMechanicalTestingofSteelProductsA644TerminologyRelatingtoIronCastingsA732/A732MSpecificationforCastings,Investment,Car-bonandLowAlloySteelforGeneralApplication,andCobaltAlloyforHighStrengthatElevatedTemperaturesE8TestMethodsforTensionTestingofMetallicMaterials2.2MilitaryStandard:3MIL-STD-129MarkingforShipmentandStorage3.OrderingInformation3.1Ordersformaterialtothisspecificationshallincludethefollowinginformation:3.1.1ASTMdesignation,3.1.2Gradeofductileironrequired(seeTable1,andSections4and9),3.1.3Specialproperties,ifrequired(seeSection7),3.1.4Ifadifferentnumberofsamplesarerequired(seeSection10),3.1.5Certification,ifrequired(seeSection14),and3.1.6Specialpreparationfordelivery,ifrequired(seeSec-tion15).4.TensileRequirements4.1Theironrepresentedbythetestspecimensshallcon-formtotherequirementsastotensilepropertiespresentedinTables1and2.Theiron...